Wort soft boiling process and equipment

A wort, gentle technology, applied in the field of beer brewing, can solve the problems of large evaporation of wort, high heat load of wort, easy aging of beer, etc., to reduce evaporation rate, reduce heat load of wort, and reduce beer aging substances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

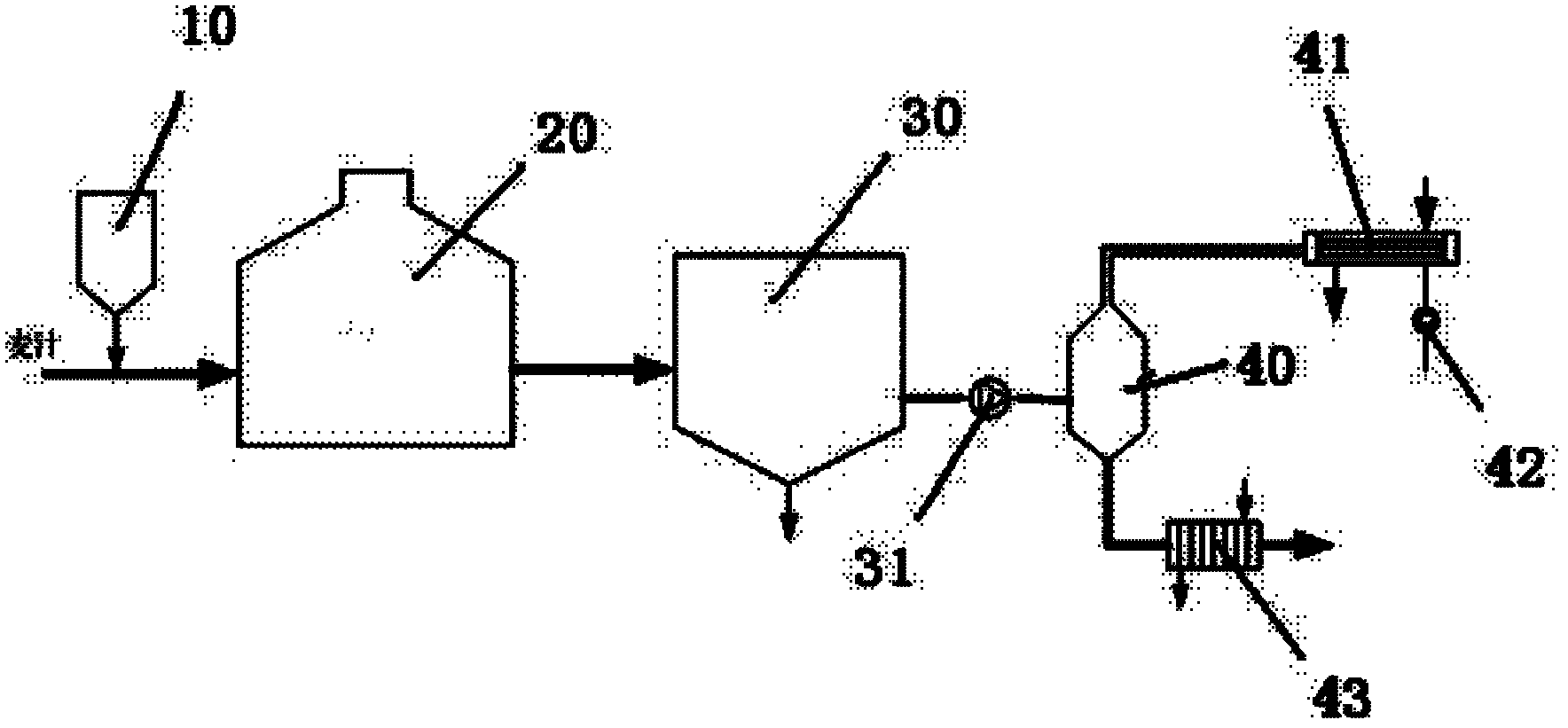

[0033] A kind of wort gentle boiling process that the present invention proposes, adopts following three steps:

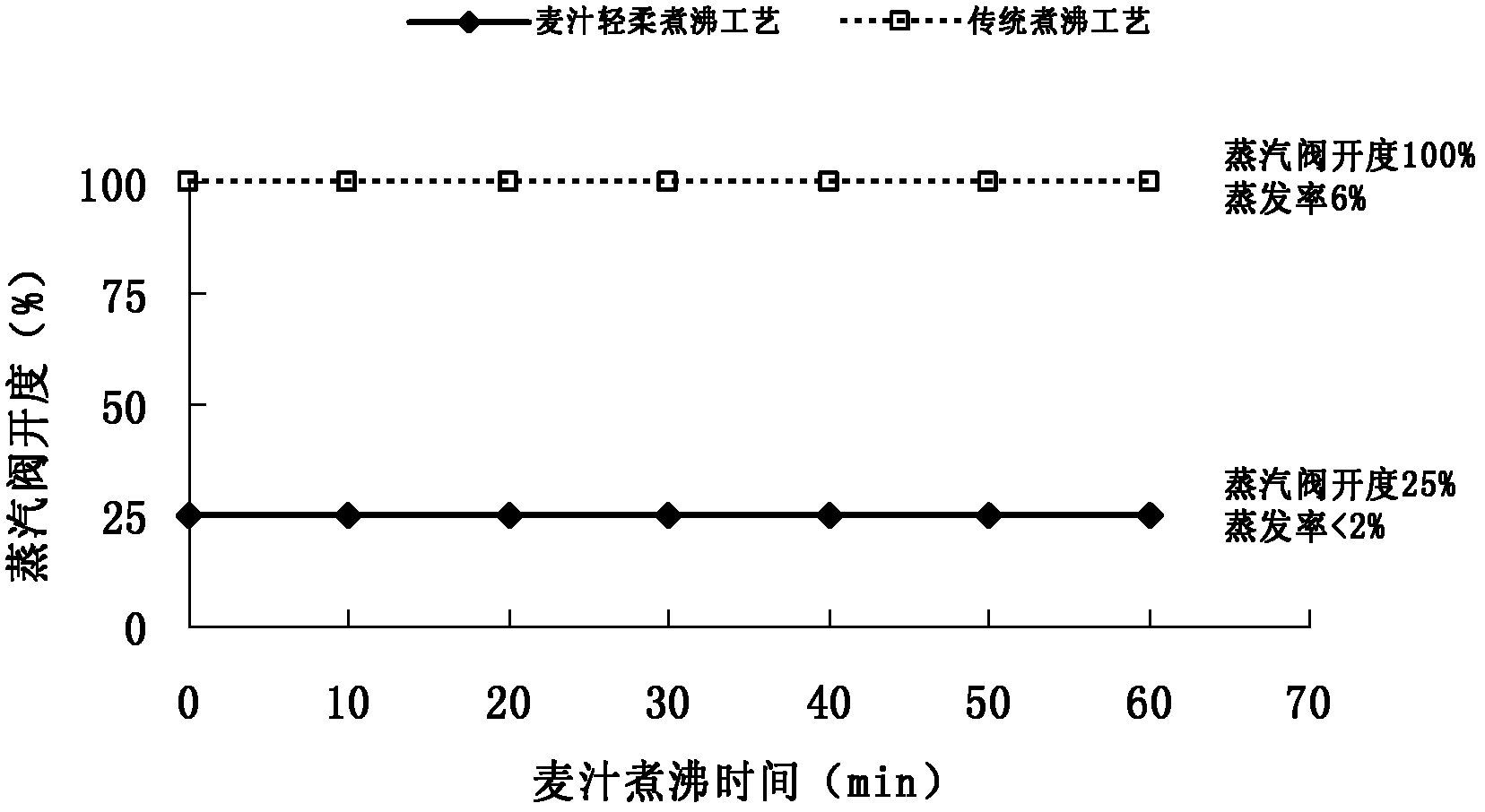

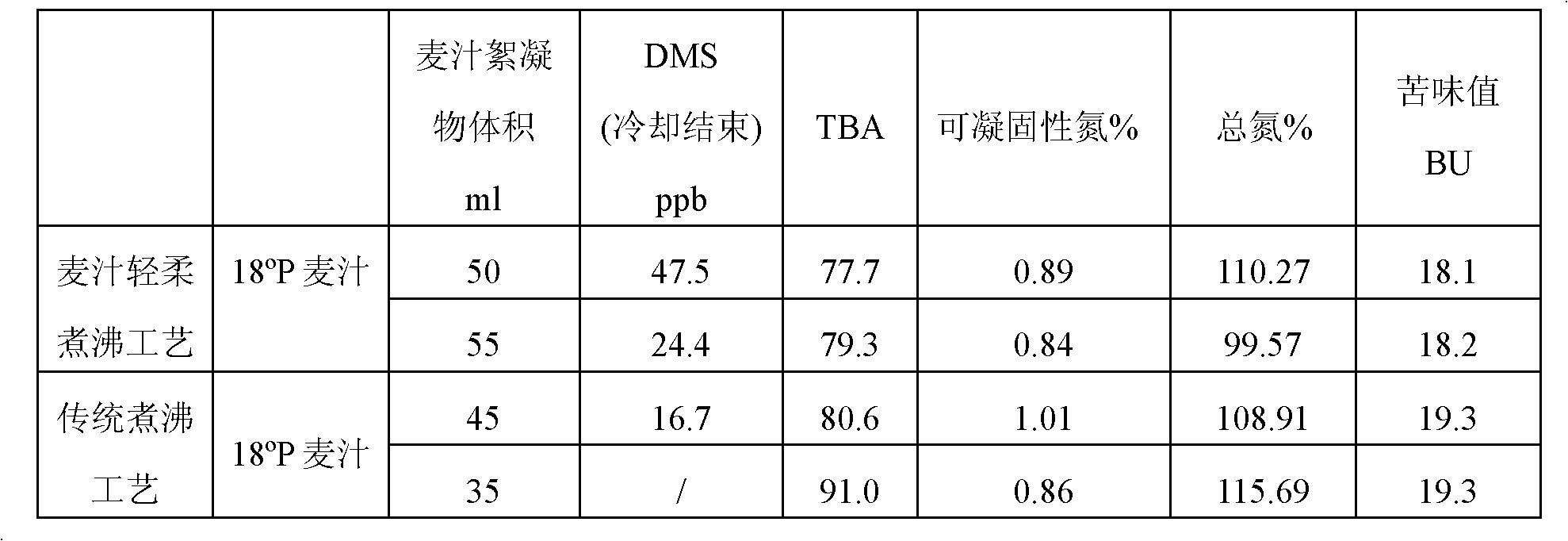

[0034] A. During the whole wort boiling process, control the opening of the steam valve to 15% to 30%, and control the boiling time to no more than 60 minutes, so that the evaporation rate in the wort boiling stage is lower than 2%, which is beneficial to reduce the heat load of the wort and make the wort Reduce beer aging substances and improve beer quality;

[0035] B. The hops or hop products that need to be added are added to the wort after the α-acid pre-isomerization process, so that the hop isomerization process will not be affected by the reduction of steam usage and boiling time, so that the bitterness value of the wort is the same as The traditional boiling process remains the same; aroma hops do not need to go through the hop pre-isomerization process.

[0036] C. After the wort is boiled, the wort vacuum evaporation system can volatilize the dimethyl s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com