Dyeing method for water-soluble polyvinyl alcohol nonwovens

A non-woven fabric and polyvinyl alcohol technology, applied in the field of textile dyeing and finishing, can solve the problems of fabric stiffness, high cost, poor color fastness of dyed products, etc., and achieve the effect of good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

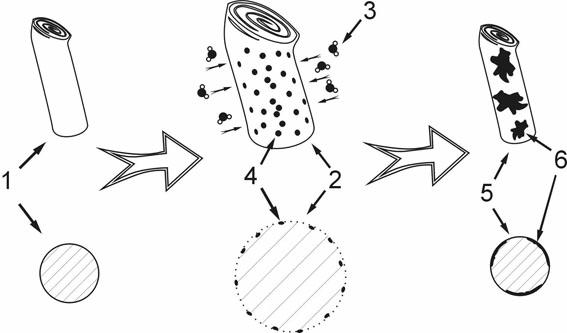

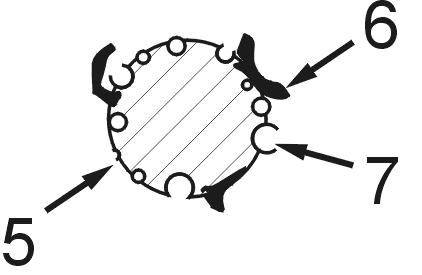

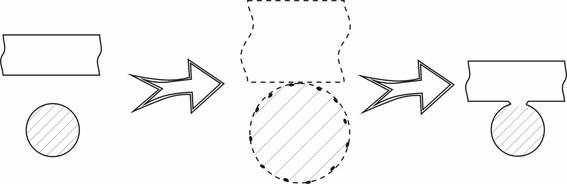

Image

Examples

Embodiment 1

[0039] The fabric is made of water-soluble polyvinyl alcohol spunlace nonwoven fabric with a weight of 60 grams per square meter. The formula of the dyeing solution is as follows:

[0040] Blue printing paste: 2g / L

[0041] Black printing paste: 0.5g / L

[0042] Acrylic adhesive: 5g / L

[0043] After the blue printing color paste and the black printing color paste are fully stirred in water, add the binder before use, and continue to stir evenly to form a dye solution. Before being delivered to the pre-dye liquor tank 10, it needs to be filtered to remove possible impurities in the dye liquor.

[0044] The device used in this example is Figure 4 shown.

[0045] When the temperature of the dyeing solution was measured to be 30°C, the nip roller 12 was pressurized to 0.6 MPa, and a small piece of cloth sample was tested to obtain a nip rate of 180%. Adjust the temperature in each district of the drying oven 16 to be 105° C., and the fastest drying speed tested at the outlet ...

Embodiment 2

[0053] The fabric is made of water-soluble polyvinyl alcohol spunlace nonwoven fabric with a weight of 60 grams per square meter. The formula of the dyeing solution is as follows:

[0054] Navy blue printing paste: 3.25g / L

[0055] Black printing paste: 0.25g / L

[0056] Acrylic adhesive: 5g / L

[0057] After the navy blue printing color paste and black printing color paste are fully stirred in water, add the binder before use, and continue to stir evenly to form a dye solution. Before being delivered to the pre-dye liquor tank 10, it needs to be filtered to remove possible impurities in the dye liquor.

[0058] The device used in this example is Figure 5 , adding a water bath heating device.

[0059] When the measured dyeing solution temperature was 33°C, the nip roll 12 was pressurized to 0.6MPa, and a small piece of cloth sample was tested to obtain a nip rate of 165%. Adjust the temperature in each district of the drying oven 16 to be 105° C., and the fastest drying sp...

Embodiment 3

[0067] The fabric is made of water-soluble polyvinyl alcohol spunlace nonwoven fabric with a weight of 60 grams per square meter. The formula of the dyeing solution is as follows:

[0068] Green printing paste: 2.5g / L

[0069] Black printing paste: 0.5g / L

[0070] Acrylic adhesive: 5g / L

[0071] After the green printing color paste and the black printing color paste are fully stirred in water, add the binder before use, and continue to stir evenly to form a dye solution. Before being delivered to the pre-dye liquor tank 10, it needs to be filtered to remove possible impurities in the dye liquor.

[0072] use Image 6 In the continuous liquid feeding device shown, the configured dye solution is added to the high level tank 22, and the valve in front of the float level control valve 24 is adjusted to ensure that when the high level tank 22 is at the lowest liquid level 23, the level of the metering tank 25 can still be maintained. Supply volume. The dye solution in the mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com