Transition section-free monopile offshore wind turbine foundation structure

A technology for offshore wind turbines and infrastructure, applied in infrastructure engineering, construction, etc., can solve problems such as hidden safety hazards, and achieve the effects of firm connection, improved durability, and simple and fast leveling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

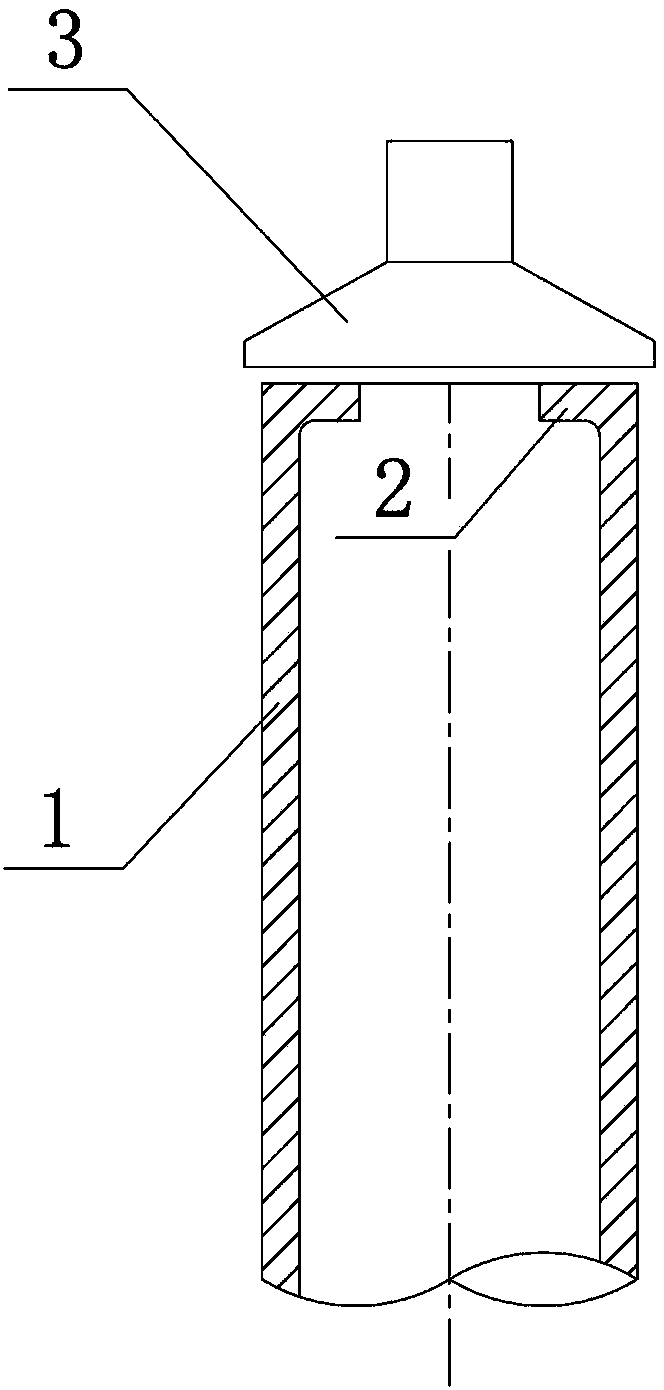

[0024] Embodiment 1: as Image 6 As shown, this embodiment includes a super-large-diameter steel pipe pile 1 driven into the seabed to a certain depth, the pile diameter is 4000mm~6500mm, the top of the pile is welded to the foundation top flange 2 in the factory, and the foundation top flange is arranged on the steel pipe pile 1 and the upper surface of the flange is flush with the top surface of the steel pipe pile 1. This example also includes a fan bottom section tower 13 connected to the upper end of the steel pipe pile 1 , and a bottom section tower flange 12 is provided at the bottom of the fan bottom section tower 13 . A double gasket leveling structure is set between the bottom tower flange 12 and the foundation top flange 2, and the two flanges are tightly connected by bolts 10 and nuts 11.

[0025] Among them, the double gasket leveling structure includes two gaskets I9 with exactly the same specifications. The gasket I is an annular gasket with uniform height chan...

Embodiment 2

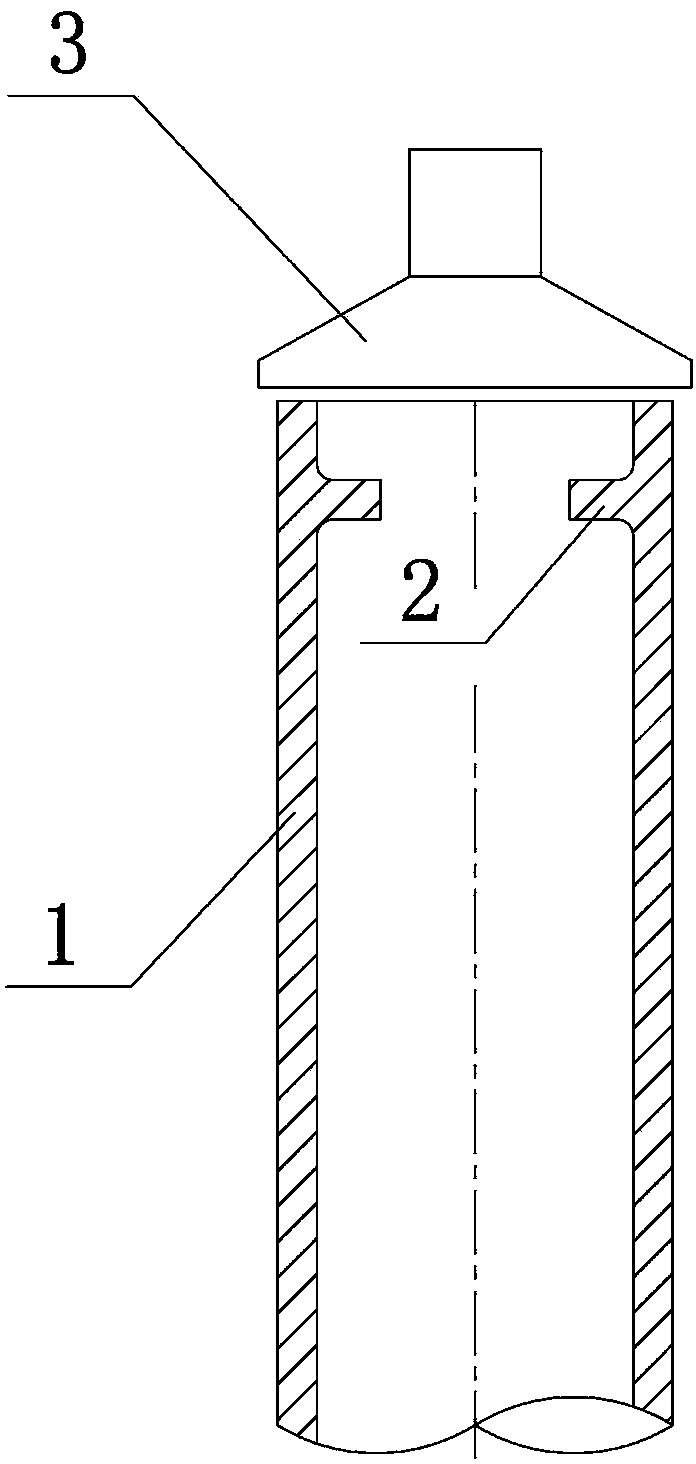

[0032] Embodiment 2: The basic structure of this embodiment is the same as that of Embodiment 1, the only difference is that a three-gasket adjustment structure is set between the top flange 2 of the foundation and the tower flange 12 of the bottom section (such as Figure 8 As shown), the structure is composed of three different specifications of circular gaskets II14 with uniform variable height and equal diameter, stacked up and down, and the height of gasket II14 varies from 20 to 80 mm. The outer diameter of the gasket Ⅱ14 is the same as that of the top flange 2 of the foundation, and a circle of bolt holes is uniformly arranged on each gasket Ⅱ14 along the circumference, and the number and position of the bolt holes are the same as those of the top flange 2 of the foundation and the tower flange of the bottom section. 12 are all corresponding; the adjustment level of gasket II14 of three specifications is 1‰, 2‰ and 5‰ respectively. Generally, 1~3 ring gaskets II14 of di...

Embodiment 3

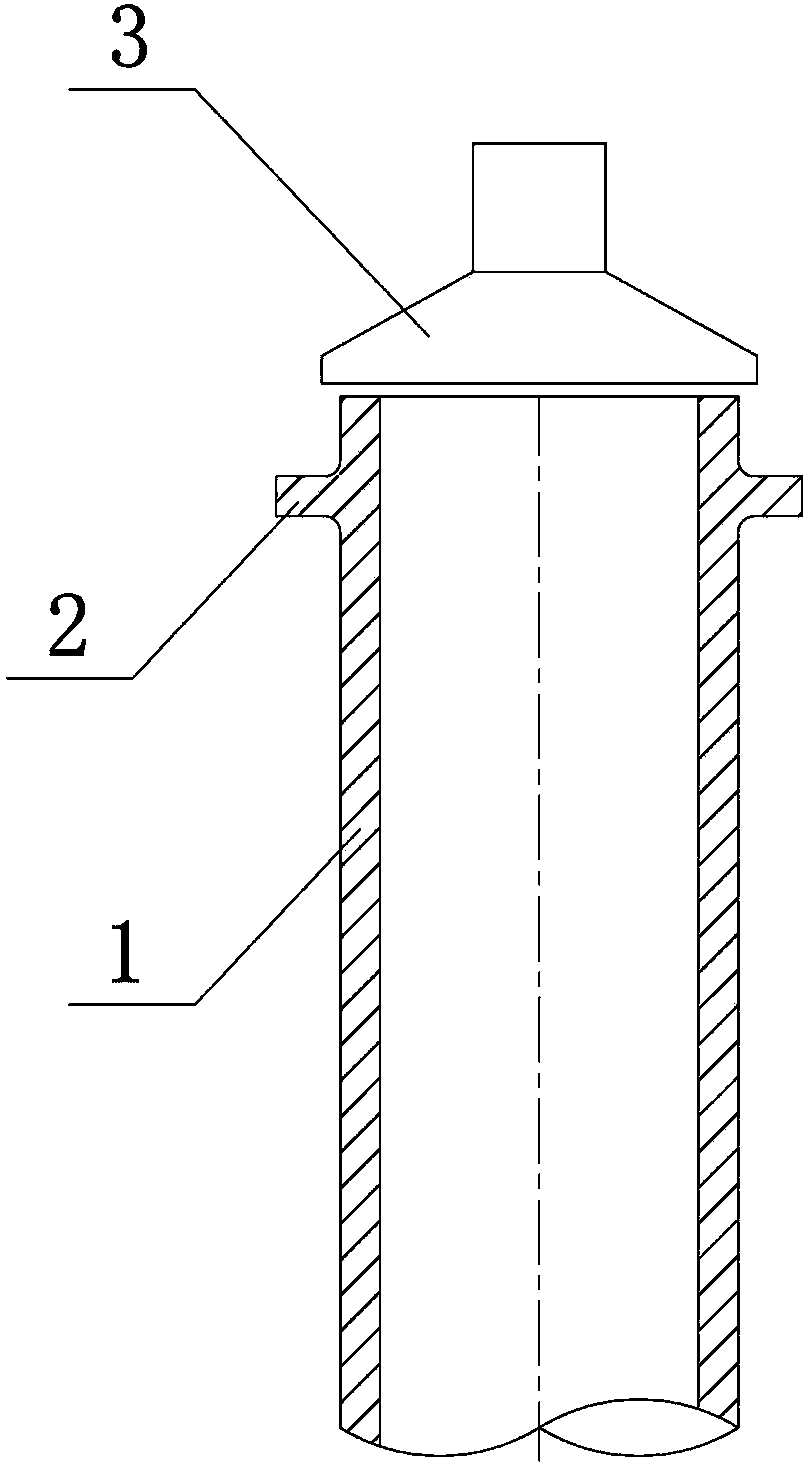

[0033] Embodiment 3: as Figure 9As shown, the top of the steel pipe pile 1 is the top flange 2 of the foundation. Due to the piling accuracy, the steel pipe pile 1 will be inclined, resulting in an inclination of the upper surface of the flange. Section tower tube 13, make tower tube verticality meet requirement. Bolts 10 and nuts 11 are used to tightly connect the bottom section tower flange 12 and the foundation top flange 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com