Method for measuring reducing agent

A reducing agent and mass flow technology, applied in the direction of air quality improvement, electronic control of exhaust treatment devices, exhaust treatment, etc., can solve problems such as SCR-catalyst conversion deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

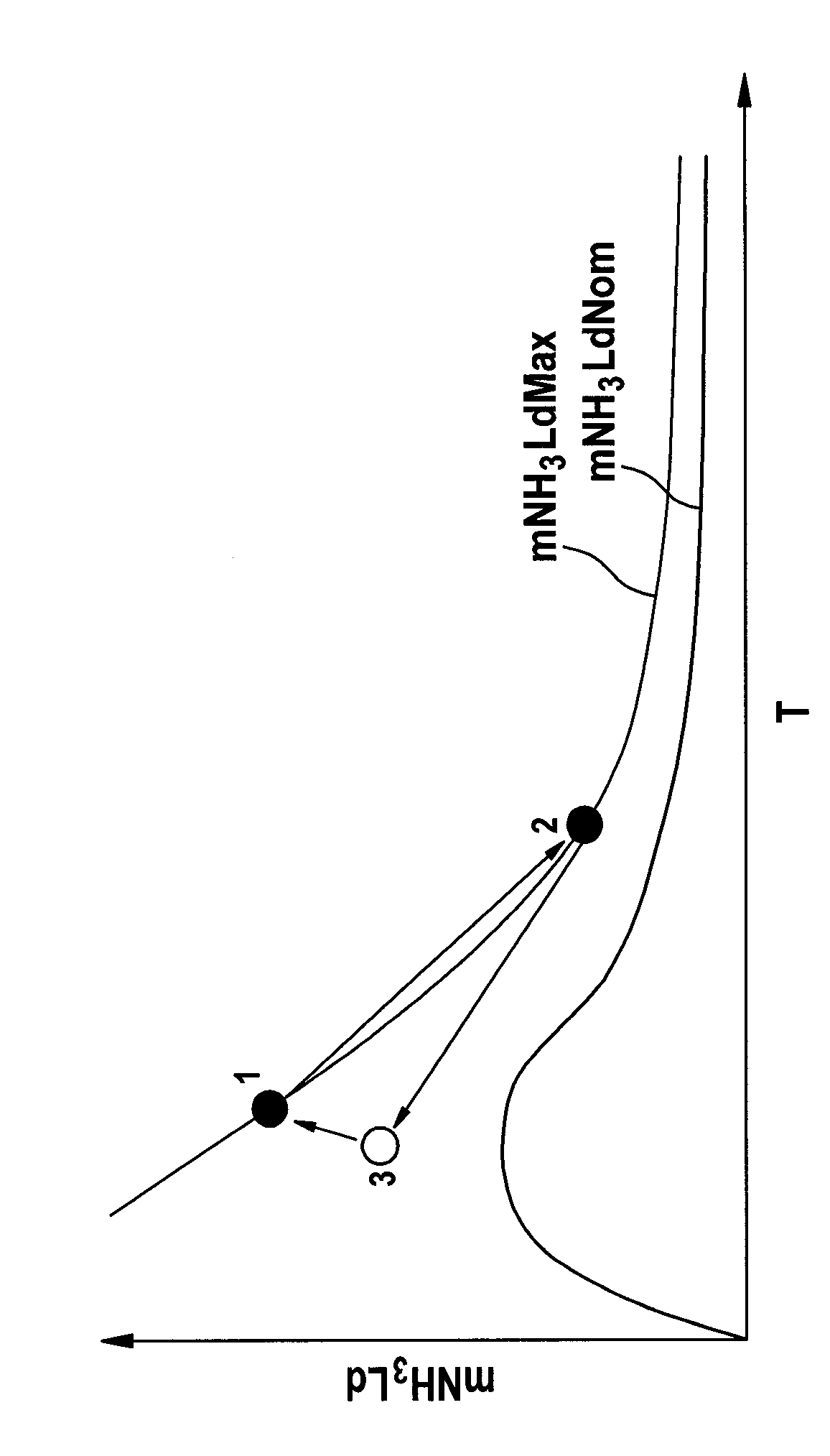

[0052] figure 1 Indicates that the abscissa is the temperature T of the SCR-catalyst, the maximum possible NH of the SCR-catalyst 3 Load mNH3LdMax. As the temperature increases the SCR-catalyst can store less NH 3 -quantity. During normal driving, phases with high and low SCR catalytic converter temperatures T alternate continuously. When the SCR-temperature T increases, especially in an overmetered system, NH can be reached quickly 3 - Storage capacity limit mNH3LdMax. The risk of ammonia being emitted into the exhaust gas after the SCR catalytic converter is high. Regulation, especially in the case of overmetering, can therefore become problematic at this stage in SCR catalytic converter systems according to the prior art, since the reductant metering can be set in the wrong direction. It can thus be seen that at an ammonia loading 1 which corresponds to the maximum possible ammonia loading mNH3LdMax at a given temperature, there is NH 3 - High risk of venting, if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com