Three-channel electrode-sharing light-emitting diode (LED) lamp of lens structure

A lens structure and technology of LED lamps are applied to LED lamps. It can solve the problems of moisture absorption and moisture absorption, easy water absorption and moisture absorption, dead lights, etc., and achieve the effect of good heat dissipation characteristics and convenient mounting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

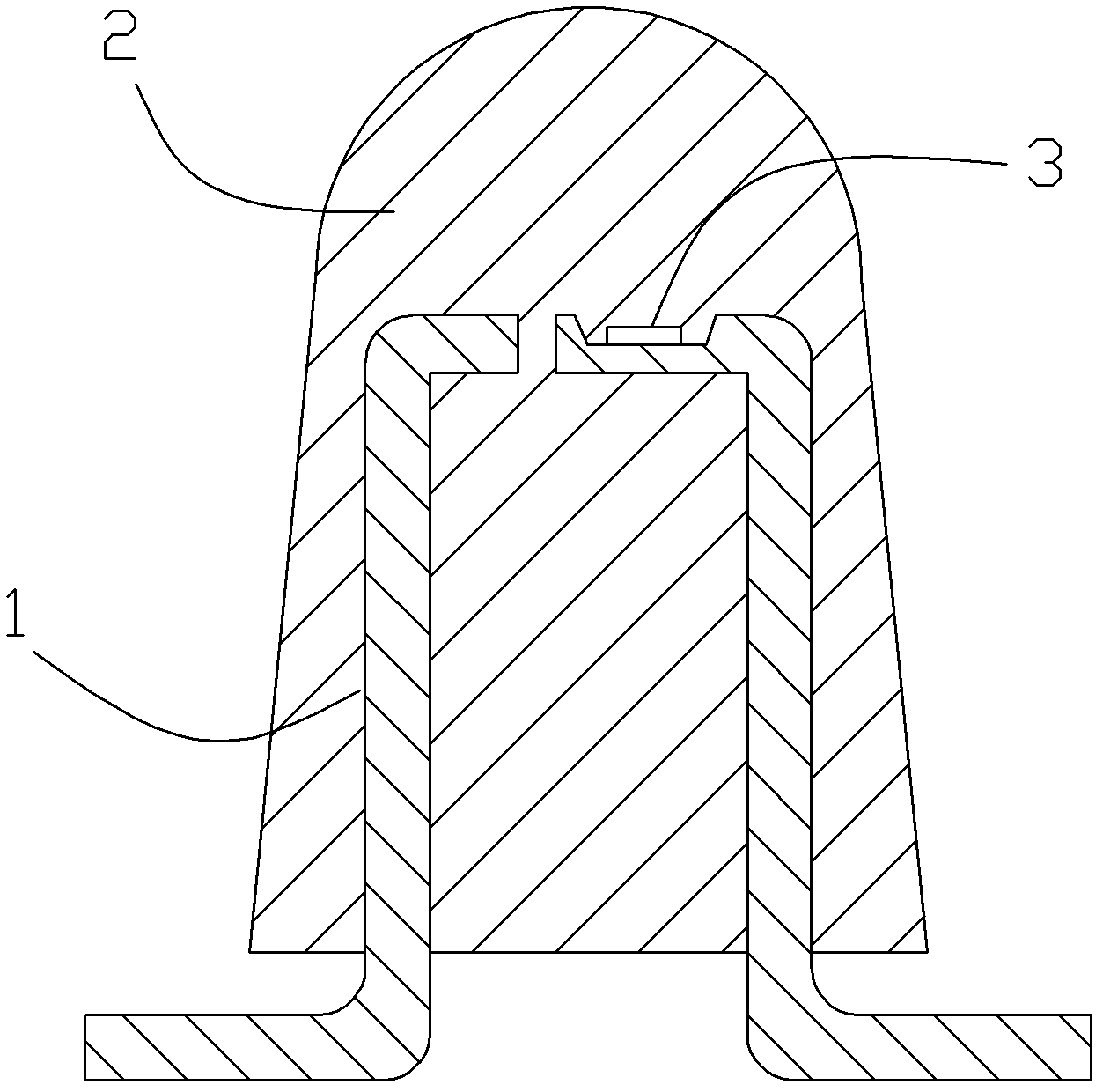

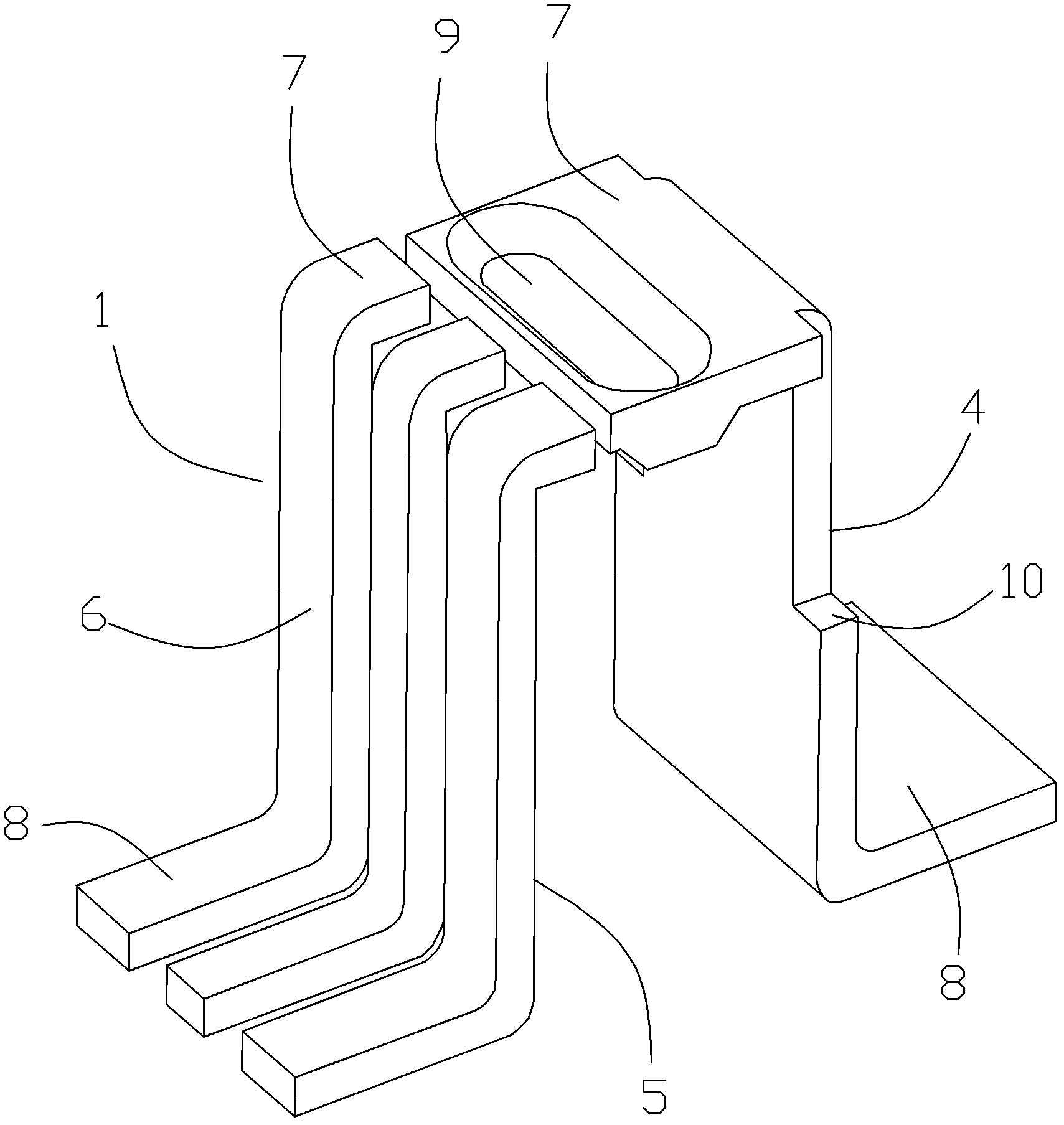

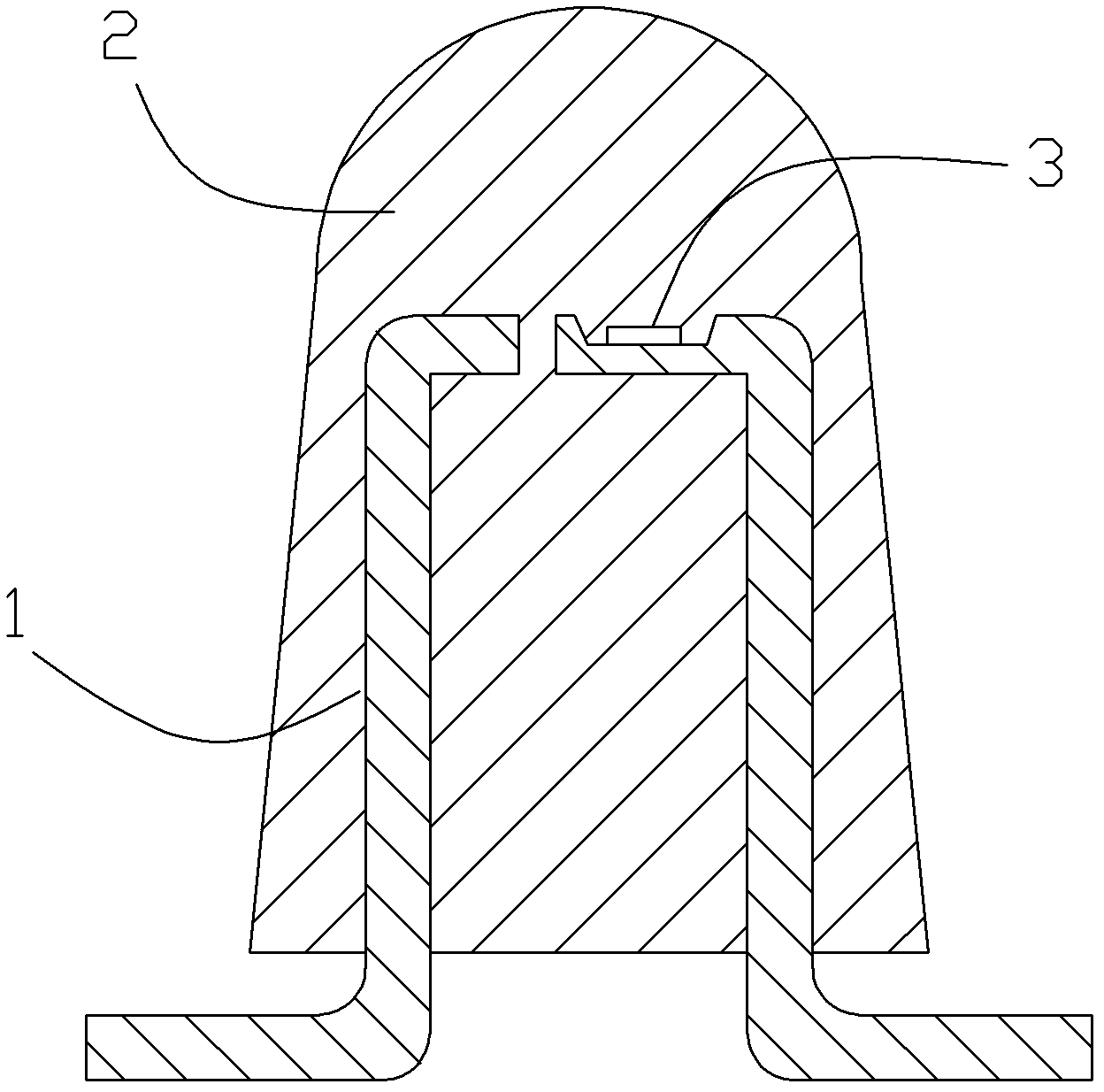

[0018] This embodiment is an LED lamp with a three-channel common-polar lens structure, such as figure 1 and figure 2 As shown, there are 4 pins 1, one of which is anode pin 4, three are cathode pins 5, the pins are flat and long, and the pins are formed by bending the pin body 6 and the upper end of the pin body The pad portion 7 and the mounting portion 8 formed by bending the lower end of the lead body are constituted, and the pad portion and the mounting portion are bent in opposite directions. The anode pin is wider than the other three cathode pins, and the lower half of the pin body of the anode pin is wider than the upper half, and a stepped surface is formed between the upper half and the lower half of the pin body 10. A bowl 9 is concavely formed in the middle of the pad portion of the anode pin. Three light-emitting chips 3 are installed in the bowl. The positive ends of the three light-emitting chips are respectively connected to the pad portion of the anode pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com