Large-caliber head spinning die

A large-caliber, mold technology, applied in the direction of forming tools, household utensils, manufacturing tools, etc., can solve the problems that are not suitable for single pieces, small batches and multi-variety, and achieve the effect of low manufacturing cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

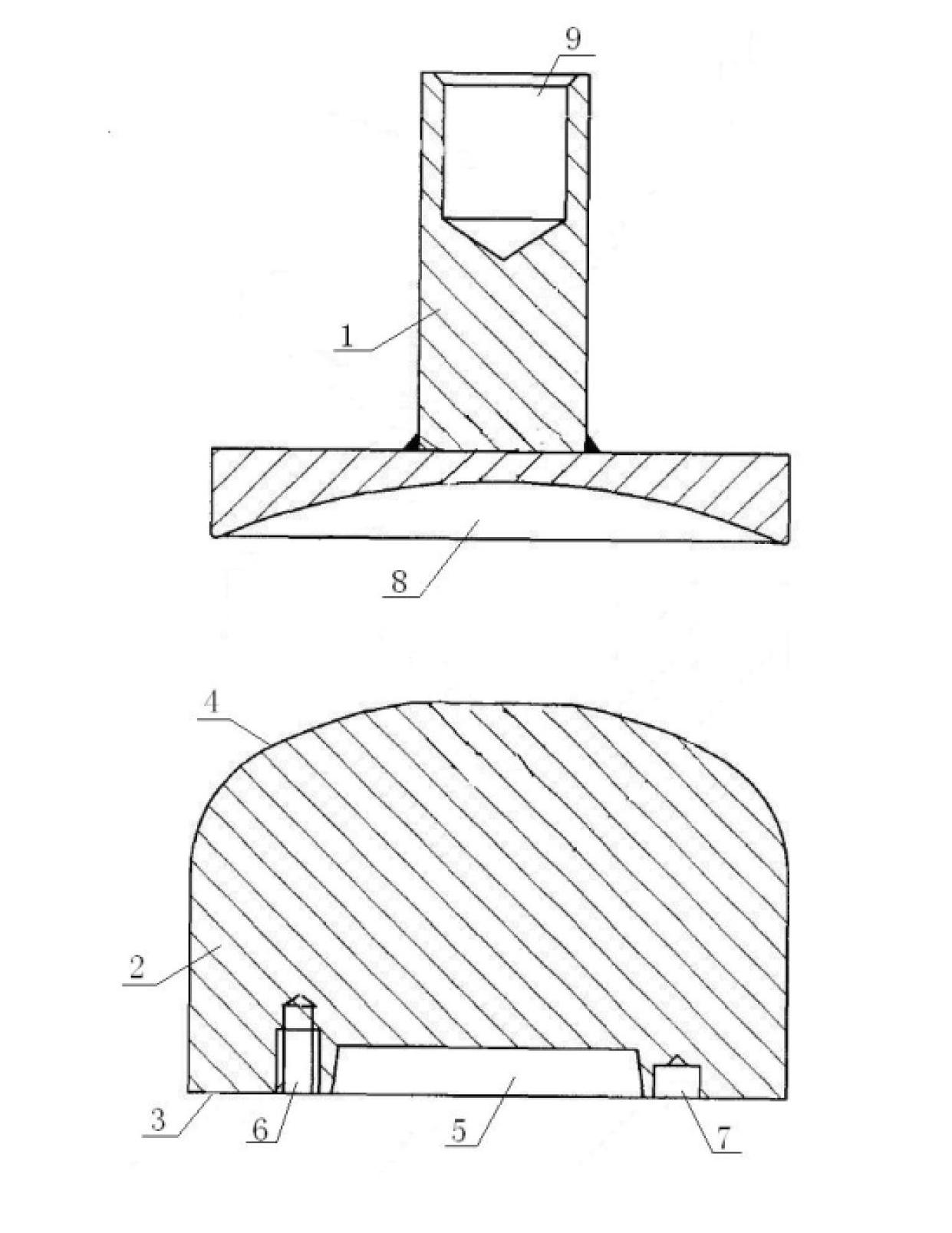

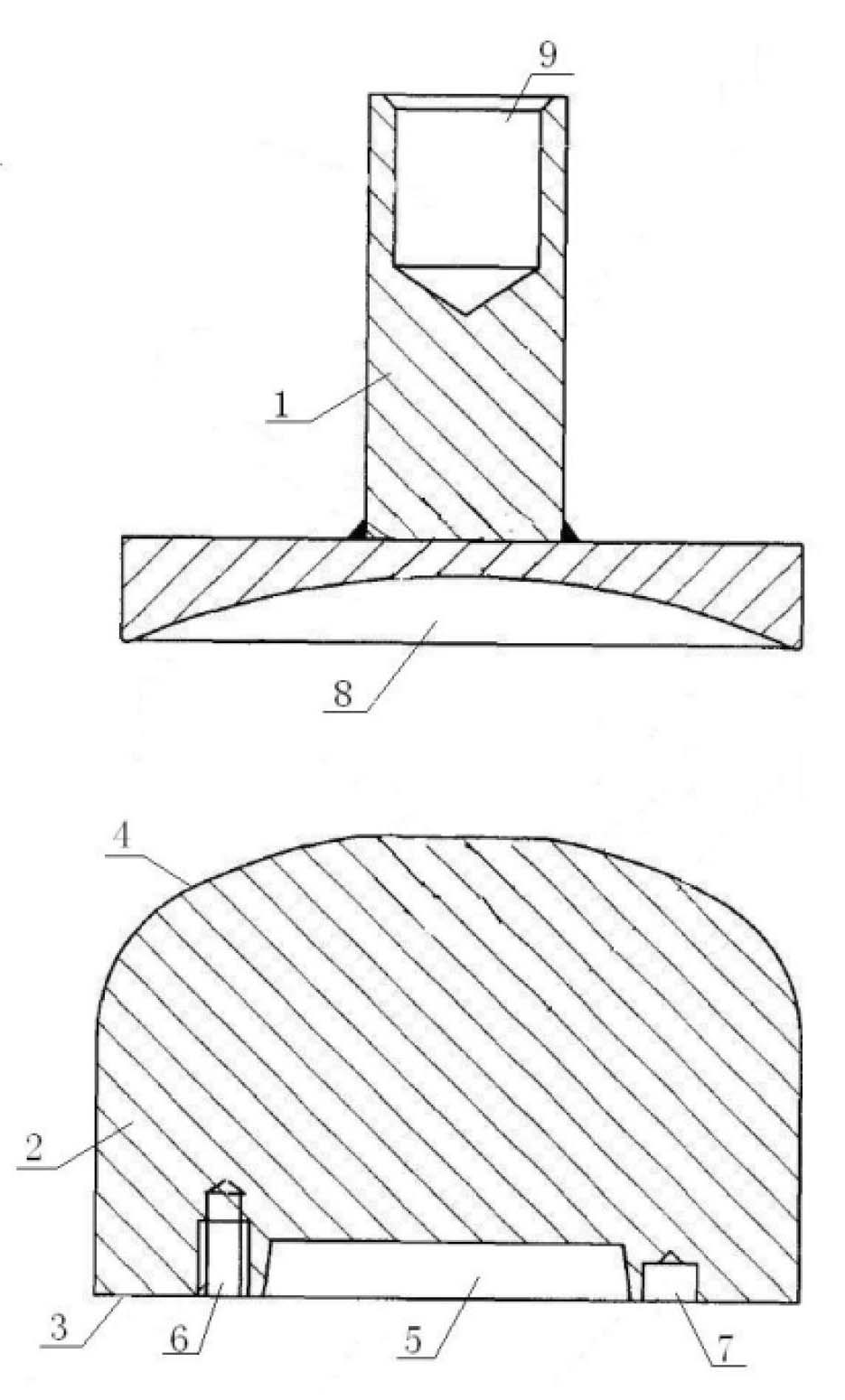

[0012] like figure 1 As shown, a large-diameter head spinning die according to the present invention includes an upper die 1 and a lower die 2; one end of the lower die 2 is a plane 3, and the other end is a large radial arc surface 4. The flat end of the lower die 2 is provided with a tapered blind hole 5, a threaded blind hole 6 is provided on one side of the tapered blind hole 5, and an escape blind hole 7 is provided on the other side; the lower part of the upper die 1 is concave. The arc surface 8 is provided with a large blind hole 9 on the upper part of the upper die 1; the lower die 2 is made of medium carbon steel; the upper die 1 is T-shaped. The invention has low manufacturing cost, can manufacture high-quality large-diameter sealing heads, and has high precision.

[0013] The parts not involved in the present invention are the same as the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com