Membrane conveying device for soft bag infusion production line

A technology of soft bag infusion and conveying device, which is applied in the direction of packaging material feeding device, transportation packaging, transportation and packaging, etc. It can solve the problems of reducing the usage rate of film materials, increasing the quality risk of infusion products, and affecting production efficiency. The effect of normal operation, improving production efficiency and membrane material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

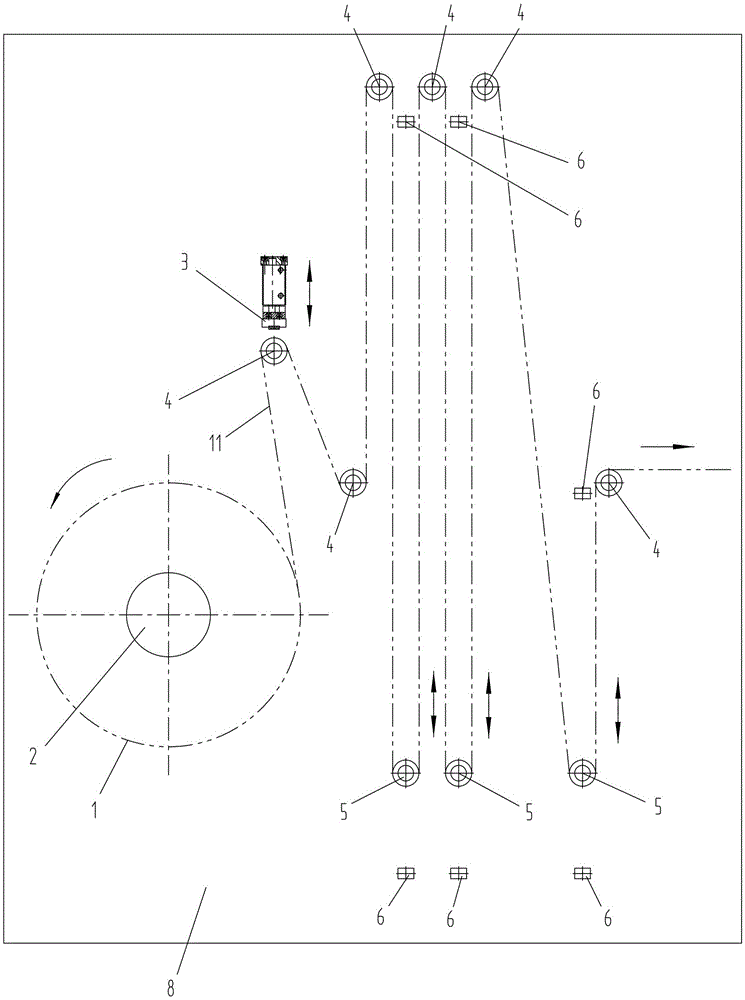

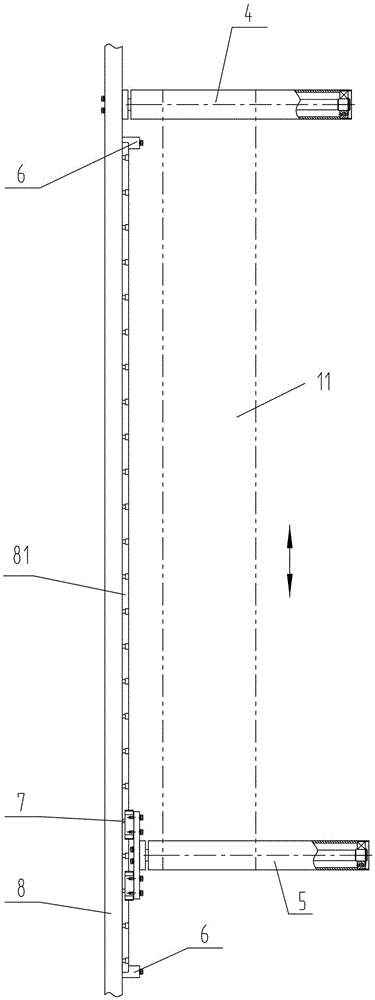

[0020] Such as figure 1 As shown, the film conveying device for the soft bag infusion production line of the present invention includes a rotating film feeding mechanism 2 and a roller conveying mechanism. The rotating film feeding mechanism 2 is used to install the film roll 1 and rotate the film 11. The roller conveying mechanism includes two or more fixed rollers 4 and more than one moving roller 5 for winding the film 11. The moving roller 5 can move in a direction close to or away from the fixed roller 4 to change the entire roller conveying mechanism. The film material 11 is wound around the length. Along the winding direction of the film material 11, the moving roller 5 is arranged between two adjacent fixed rollers 4, and the moving roller 5 closest to the rotating film feeding mechanism 2 is provided with a pressing mechanism that can stop the film material 11 from moving forward. 3. Such as figure 2 As shown, in this embodiment, the fixed roller 4 is fixedly install...

Embodiment 2

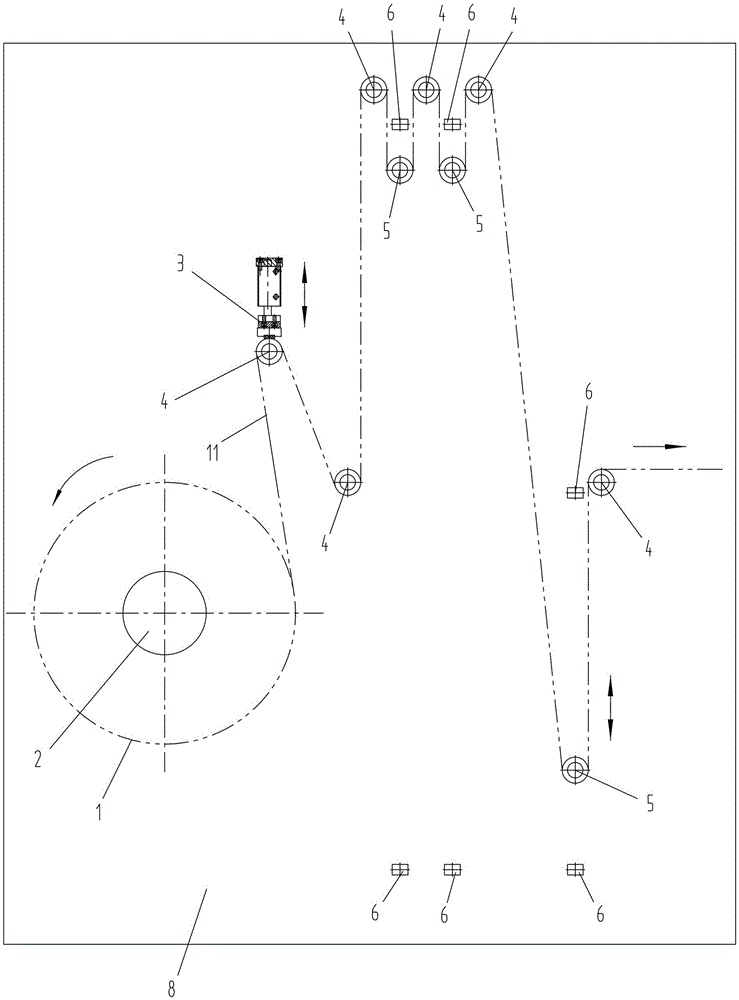

[0025] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of embodiment 1, but the difference is that under the premise that the length of the reserved film 11 determined according to the film change time is sufficient, the two fixed rollers 4 are removed, that is, along In the winding direction of the film material 11, only one fixed roller 4 is arranged before the moving roller 5 closest to the rotating film feeding mechanism 2, and the structure is more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com