Hoisting mechanism of multi-lifting-point joint crane

A hoisting mechanism and crane technology, applied in the direction of load block, load hanging components, transportation and packaging, etc., can solve the problem that the hoisting points of a single hoisting mechanism cannot be hoisted synchronously, the hoisting transmission efficiency is low, and the construction and installation are inconvenient, etc. problems, to achieve the effects of reduced construction difficulty and operating costs, shortened installation period, and reduced pulley magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Now in conjunction with the drawings, the present invention will be further described in detail:

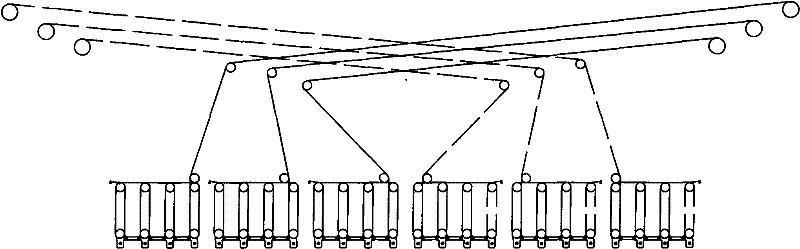

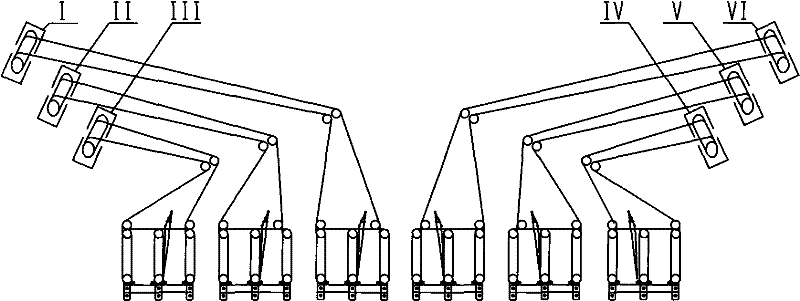

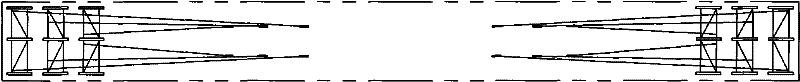

[0038] The multi-lifting point crane hoisting mechanism is used on a 20,000-ton super-heavy crane, such as figure 2 , image 3 As shown, each main beam is equipped with 6 sets of hoisting mechanisms, which are represented by Roman numerals I, II, III, IV, V, VI;

[0039] Each set of hoisting mechanism, such as Figure 4 As shown, they all include a duplex reel set 14 with a spacer 20 in the middle, such as Picture 11 As shown, it also includes two steel wire ropes 10, 11, two upper guide pulleys 12, 13, two lower guide pulleys 7, 9, and three fixed pulley sets 4 located on the same side span end of the main beam as the duplex drum set. , 5, 6 and three corresponding hook groups 1, 2, 3, respectively, as Picture 9 , Picture 10 As shown, as well as two hook connectors 15, 16, respectively, as Figure 7 with Figure 8 Shown

[0040] The two steel wire ropes 10, 11 are each wound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com