Dust removal system on coke oven machine side

A technology of dust removal system and coke oven, used in coke oven, furnace prevention/removal of scale, petroleum industry, etc., can solve the problems of poor sealing and poor dust removal effect, and achieve the reduction of soot overflow, long furnace life, The effect of improving the level of environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

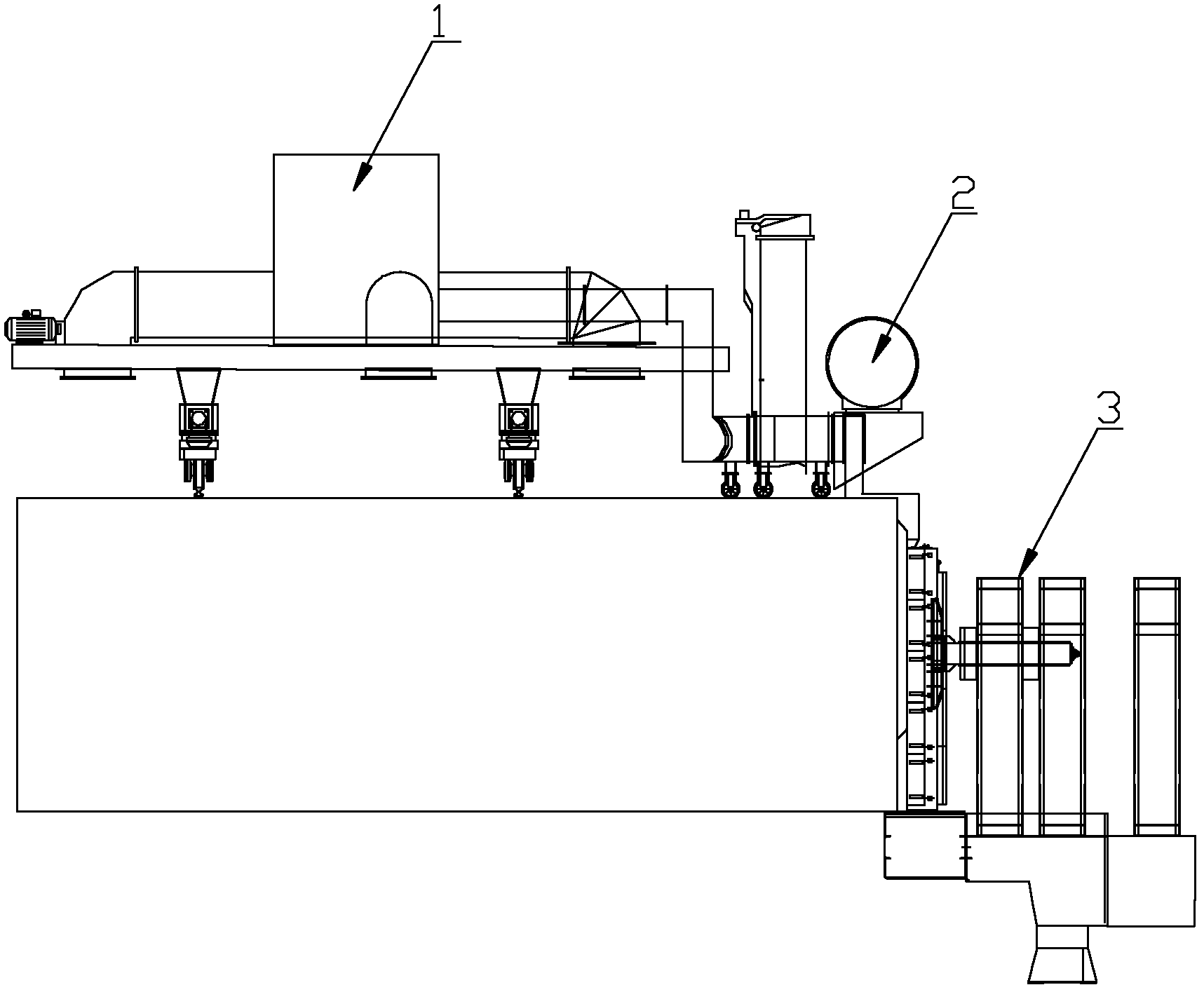

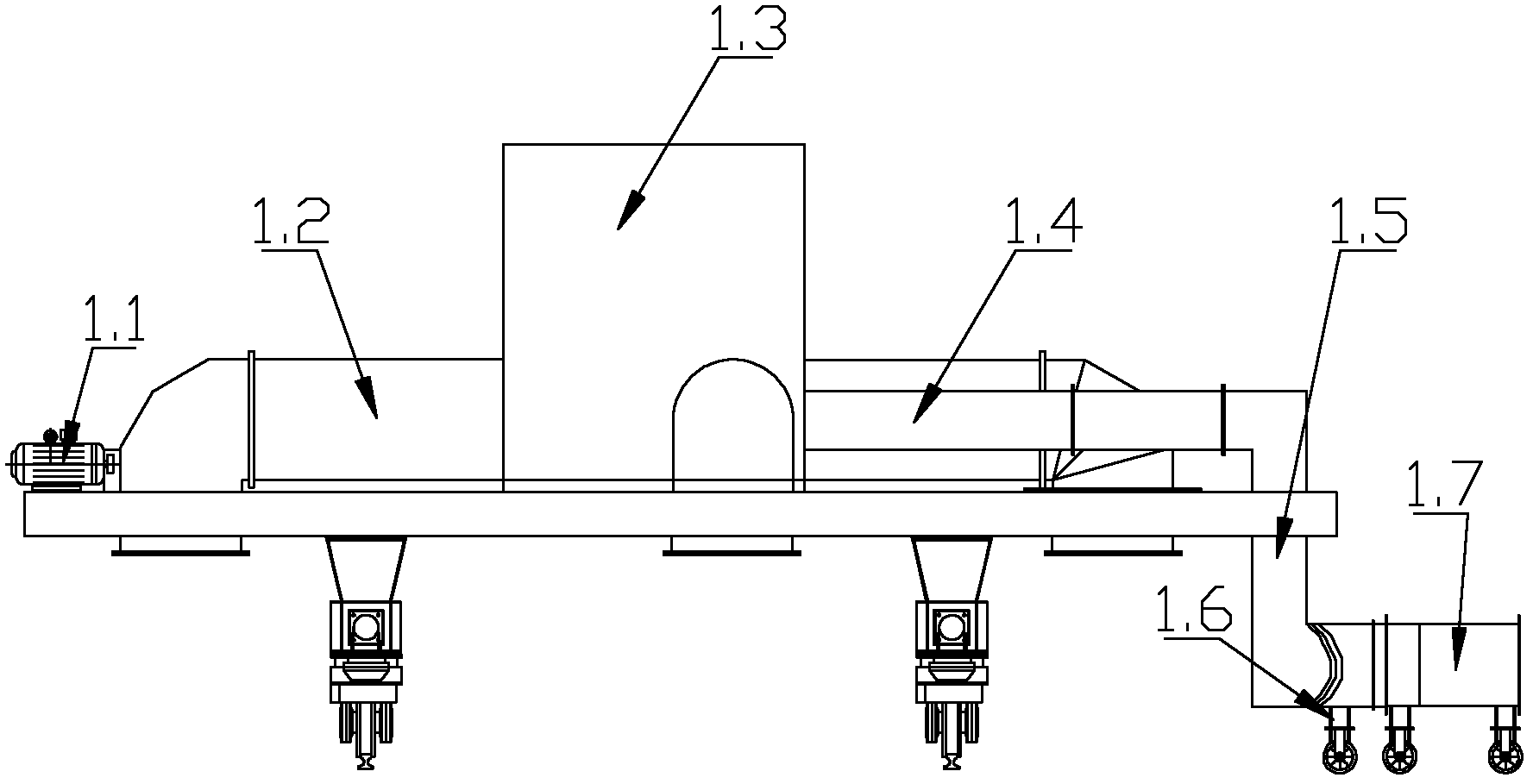

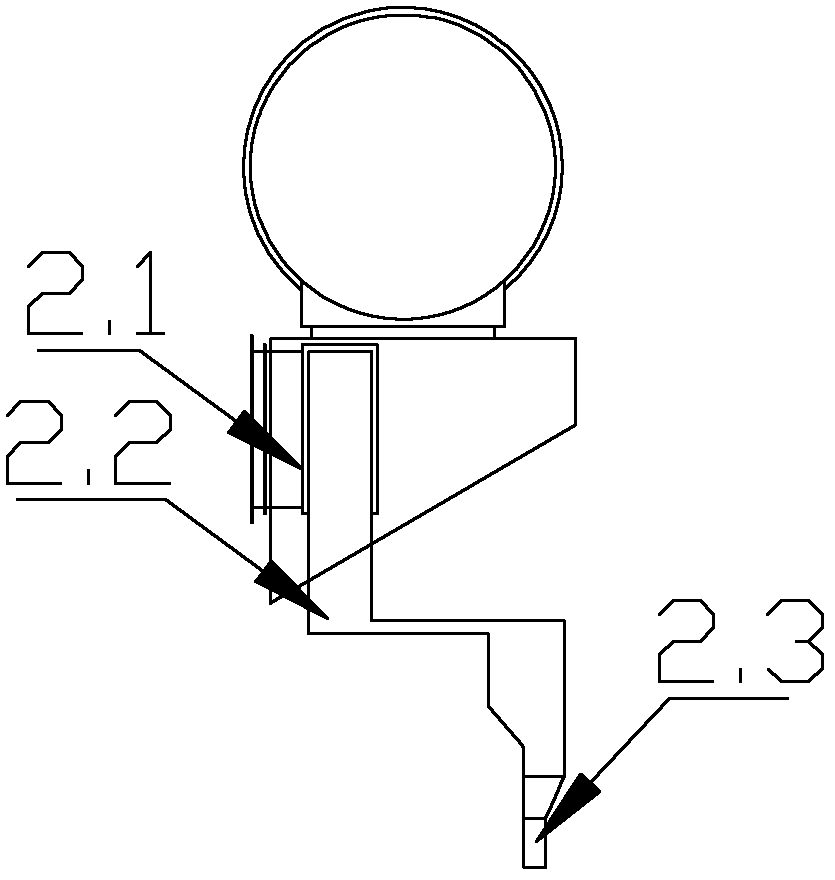

[0013] Such as figure 1 The coke oven machine-side dedusting system shown is composed of furnace top smoke and dust collection device 1, machine-side smoke and dust collection device 2 and coal charging sealing device 3; furnace top smoke and dust collection device 1 includes axial flow fan 1.1, connecting pipe 1.2, Smoke collecting hood 1.3, dust collecting pipe I 1.4, telescoping pipe 1.5 and walking trolley 1.6 such as figure 2 Shown; one end of the axial flow fan 1.1 is connected and fixed with the smoke collection hood 1.3 through the connecting pipe 1.2, and the other end of the axial flow fan 1.1 is connected with the smoke collection pipeline of the furnace top smoke guiding vehicle; the smoke collection cover 1.3 is connected with the smoke collection pipe I 1.4 It is welded and fixed by reinforcing ribs; the dust collection pipe I 1.4 and the telescopic pipe 1.5 are connected and fixed by bolts; the walking trolley 1.6 is provided with a docking guide sleeve I 1.7 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com