Corynebacterium acetoacidophilum strain and method for producing succinic acid therefrom

A technology of Corynebacterium acetoacetophilus and succinic acid, which is applied in the field of bioengineering, can solve the problems of complex operation process, long fermentation cycle, and reduced activity, and achieve the effects of simple culture conditions, rapid growth, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

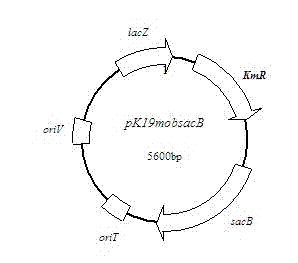

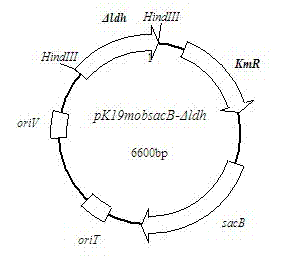

[0024] Embodiment 1, gene knockout vector pK19mob sacB -Δ ldh build

[0025] 1) PCR amplification ldh Upstream and downstream fragments of the gene: Extract Corynebacterium acetoacetophilus with a genomic DNA extraction kit (product of Sangon Company) C. acetoacidophilum Genome of ATCC 13870. According to Gene Bank C. glutamicum Primers were designed for the whole genome sequence of ATCC 13032 (Gene Bank No: Nc_006958.1). Using the extracted genome as a template, P1 (SEQ ID No.1) and P2 (SEQ ID No.2) as primers, PCR amplification under the action of Taq enzyme (product of Guangzhou Dongsheng Company) ldh Gene upstream fragment ( ldh 503bp upstream of the start codon of the gene, namely SEQ ID No.5). With P3 (SEQ ID No.3) and P4 (SEQ ID No.4) as primers, PCR amplification ldh The downstream fragment of the gene ( ldh 500bp downstream of the gene termination codon, namely SEQ ID No.6). The sequences of the above primers are respectively:

[0026] P1: AAG...

Embodiment 2

[0033] Embodiment 2, ldh gene deletion C. acetoacidophilum Δ ldh preparation of

[0034] 1) C. acetoacidophilum Competent preparation: pick a fresh plate C. acetoacidophilum ATCC 13870, inoculated into liquid LB medium containing 1% glucose, cultivated overnight at 30°C, 200r / min, and then transferred to 30 mL containing 1% (mass volume ratio) glycine and 0.5% (volume ratio) Tween 80 In LB medium, make the starting OD 600 reach 0.5, continue culturing at 37°C, 100r / min for 20 hours to OD 600 reached 0.9. After the bacterial solution was ice-bathed, the bacterial cells were collected by centrifugation, washed 4 times, and the cells were suspended with pre-cooled 15% (volume percentage) glycerol, and distributed in 1.5 mL centrifuge tubes, 100 μL per tube. Store the competent cells in a -70°C refrigerator or directly use them for electroshock transformation.

[0035] 2) Electric shock transformation plasmid pK19mob sacB -Δ ldh : Take the competent cells out of ...

Embodiment 3-4

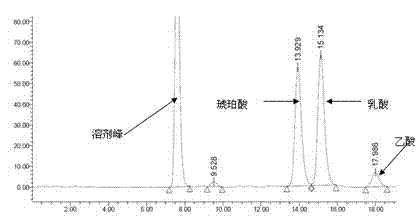

[0037] Embodiment 3-4, the method for producing succinic acid by Corynebacterium acetoacetophilus

[0038] (1) Aerobic medium (g / L): glucose 20, urea 1.2, yeast extract 4, casein 4, (NH 4 ) 2 SO 4 10, KH 2 PO 4 1.5,K 2 HPO 4 1.5, MgSO 4 ·7H 2 O 1.5, MnSO 4 ·H 2 O 0.005, FeSO 4 ·7H 2 O 0.06, thiamine 0.0004, biotin 0.0004, pH 7.0-7.2, sterilized at 115°C for 20 min.

[0039] (2) Culture medium in anoxic environment (g / L): glucose 80, carbonate 60, KH 2 PO 4 1.5,K 2 HPO 4 1.5, MgSO 4 ·7H 2 O 1.5, MnSO 4 ·H 2 O 0.005, FeSO 4 ·7H 2 O 0.06, Thiamine 0.0004, Biotin 0.0004. pH 7.0-7.2, sterilized at 115°C for 20 minutes.

[0040] Corynebacterium acetoacetophilus ATCC 13870 and YF / Δ ldh Pick a ring of fresh slant and inoculate them in the Erlenmeyer flasks with aerobic medium, culture at 35°C and 300 r / min for 36 h, expand the culture at 1% inoculum size, and collect by centrifugation after 48 h bacteria. The wet cells were transferred to a capped bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com