Closed water cooling blast furnace top distributing gear based on rapid exchange oil cylinder

A distributor and quick-change technology, applied in the direction of bell and funnel arrangement, etc., can solve problems such as difficulty in lubrication of the slewing bearing of the distributor, cumbersome replacement of hydraulic cylinders, overflow of cooling water into the blast furnace, etc., and achieve simple structure, easy maintenance and Easy maintenance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The distributor of the present invention will be described in further detail below with reference to the accompanying drawings and the embodiments of the present invention.

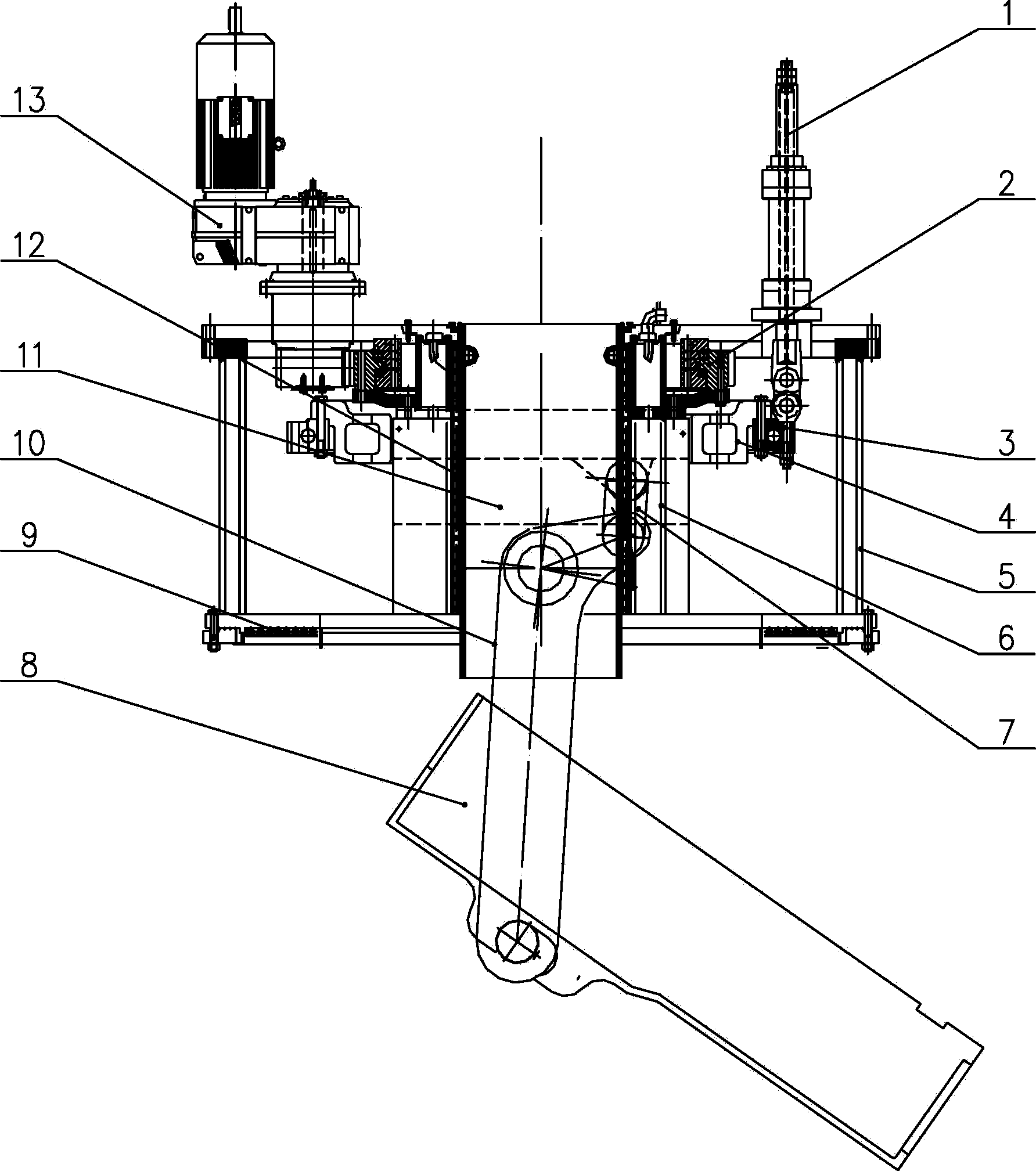

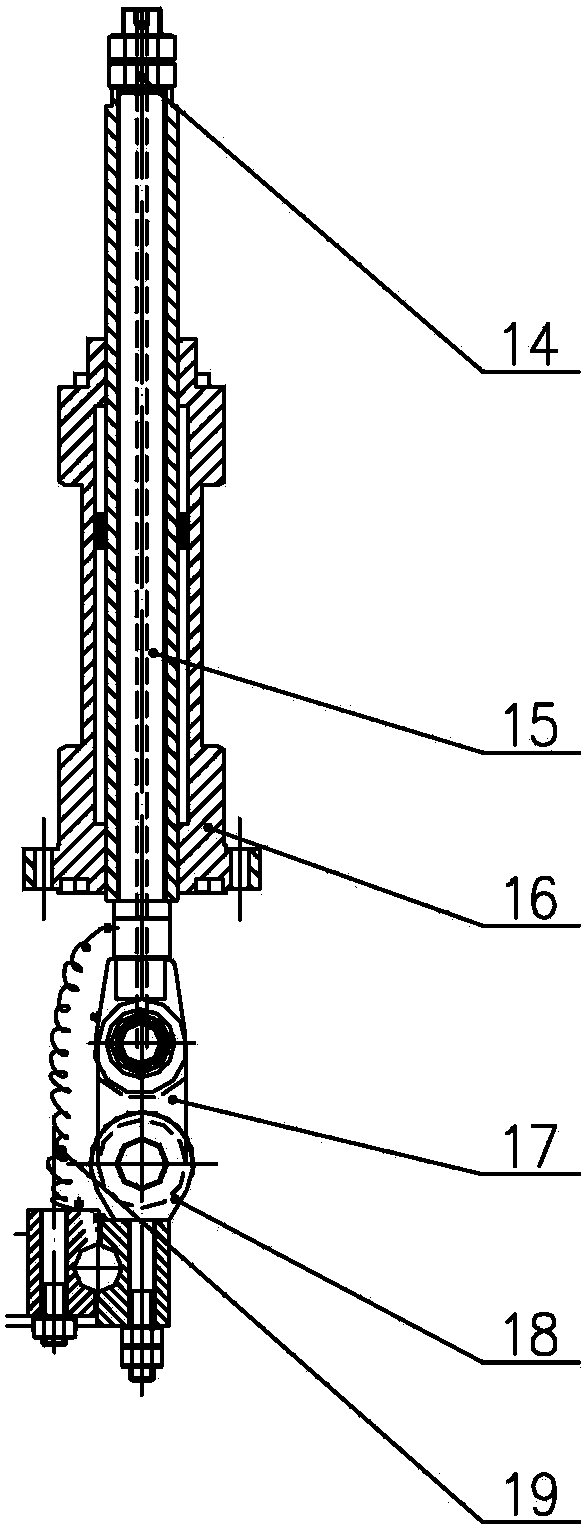

[0041] figure 1 It is a schematic diagram of the structure of the closed water-cooled blast furnace top distributor based on the quick-change oil cylinder of the present invention, such as figure 1 As shown, the basic composition of the distributor includes: lift drive assembly 1 (three pieces in total, evenly distributed); upper slewing bearing 2; lower slewing bearing 3; sliding box ring 4; distributor shell 5; rotating cylinder 6 ; connecting rod 7; chute 8; lower closed water cooling plate 9; suspension assembly 10; central throat 11;

[0042] Please refer to figure 1 , the rotary drive assembly 13 of the distributor uses a deceleration motor as a drive member. The distributor shell 5 is installed on the top steel ring of the blast furnace, and its center line coincides with the center line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com