Gas, water and coal separation device of coal-mine gas spray hole

A coal mine gas, water and coal separation technology, applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as hidden safety hazards of nozzle holes, and achieve the effect of improving efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

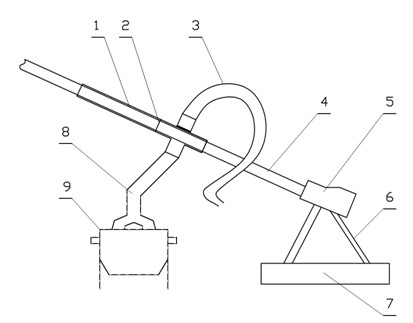

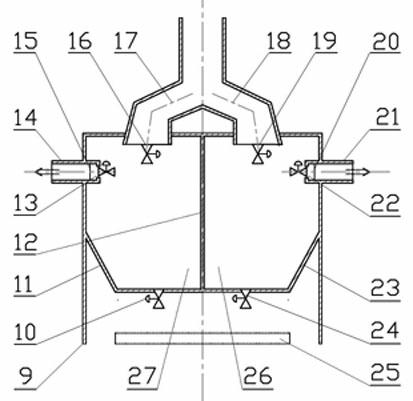

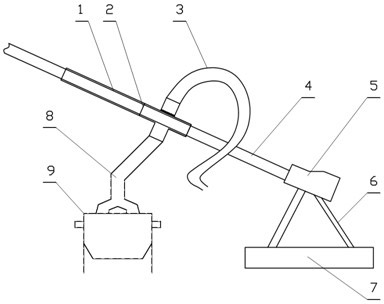

[0013] In the figure, the coal mine gas injection hole gas-water coal separation device includes drilling casing 1, cross 2, gas pre-pumping pipe 3, drill pipe 4, drilling rig 5, drilling rig support 6, platform 7, coal guide pipe 8 , Coal bunker 9, A bunker coal unloading board pressure switch 10, A bunker moving coal unloading board 11, coal bunker sub-bin board 12, A bunker gas drainage nozzle valve 13, A bunker gas drainage pipe 14, A bunker filter Net 15, A storehouse coal guide pipe valve 16, A storehouse coal guide branch pipe 17, B storehouse coal guide branch pipe 18, B storehouse coal guide pipe valve 19, B storehouse filter screen 20, B storehouse gas drainage pipe 21, B storehouse Storehouse gas drainage nozzle valve 22, second storehouse moving coal unloading plate 23, second storehouse unloading coal plate pressure switch 24, coal retaining plate 25, second storehouse 26, a storehouse 27; the coal mine gas spray hole gas-water coal separation device The sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com