Control system for internal flow field of mesh-belt kiln

A control system, mesh belt kiln technology, applied in the flow field control system in the mesh belt kiln kiln, and in the field of calcining mesh belt kiln, it can solve the problems of catalyst cracking, difficult to ensure process requirements, product quality, process temperature error, etc., to achieve Good heat and moisture exchange, avoid catalyst cracking, stabilize temperature difference and humidity difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

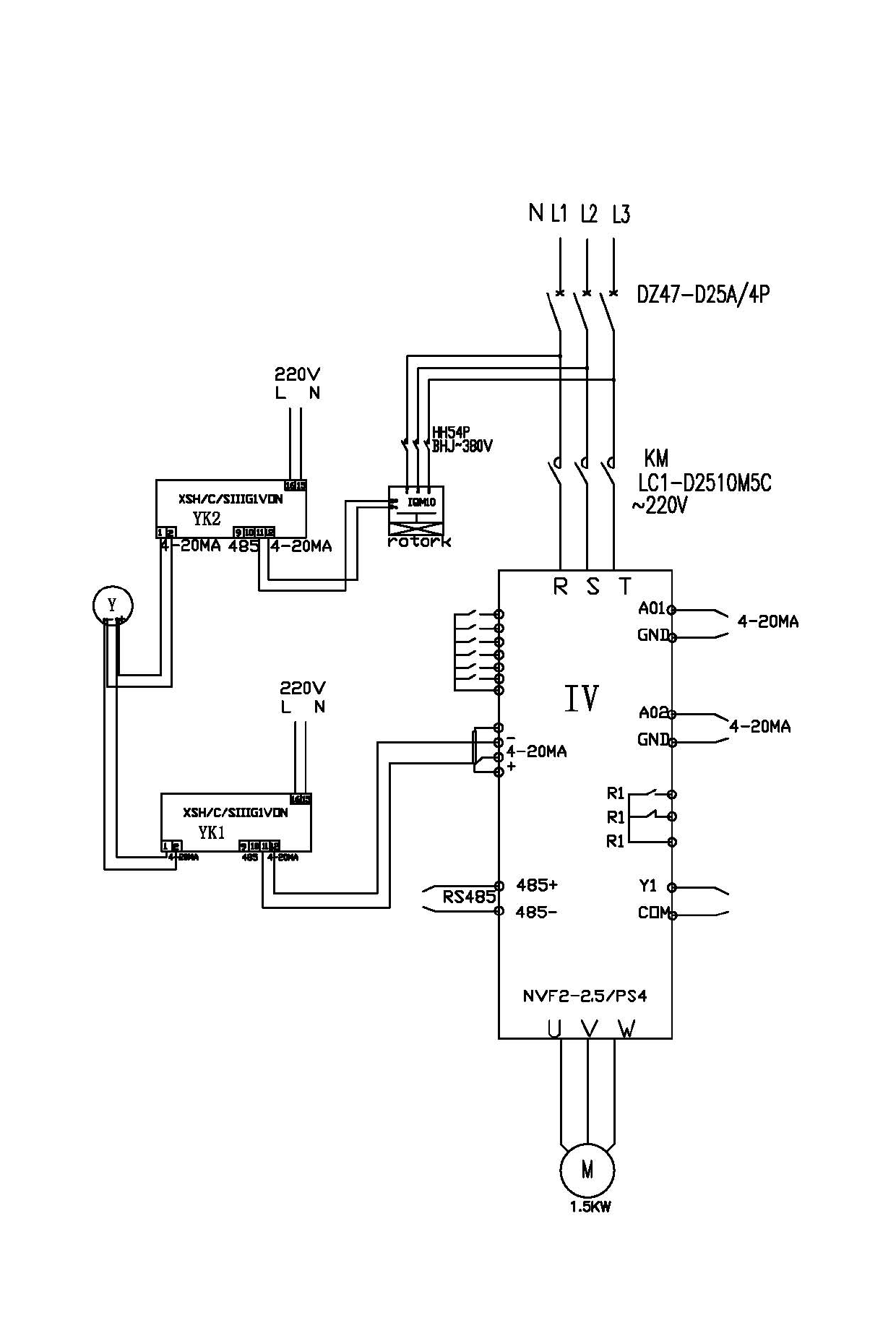

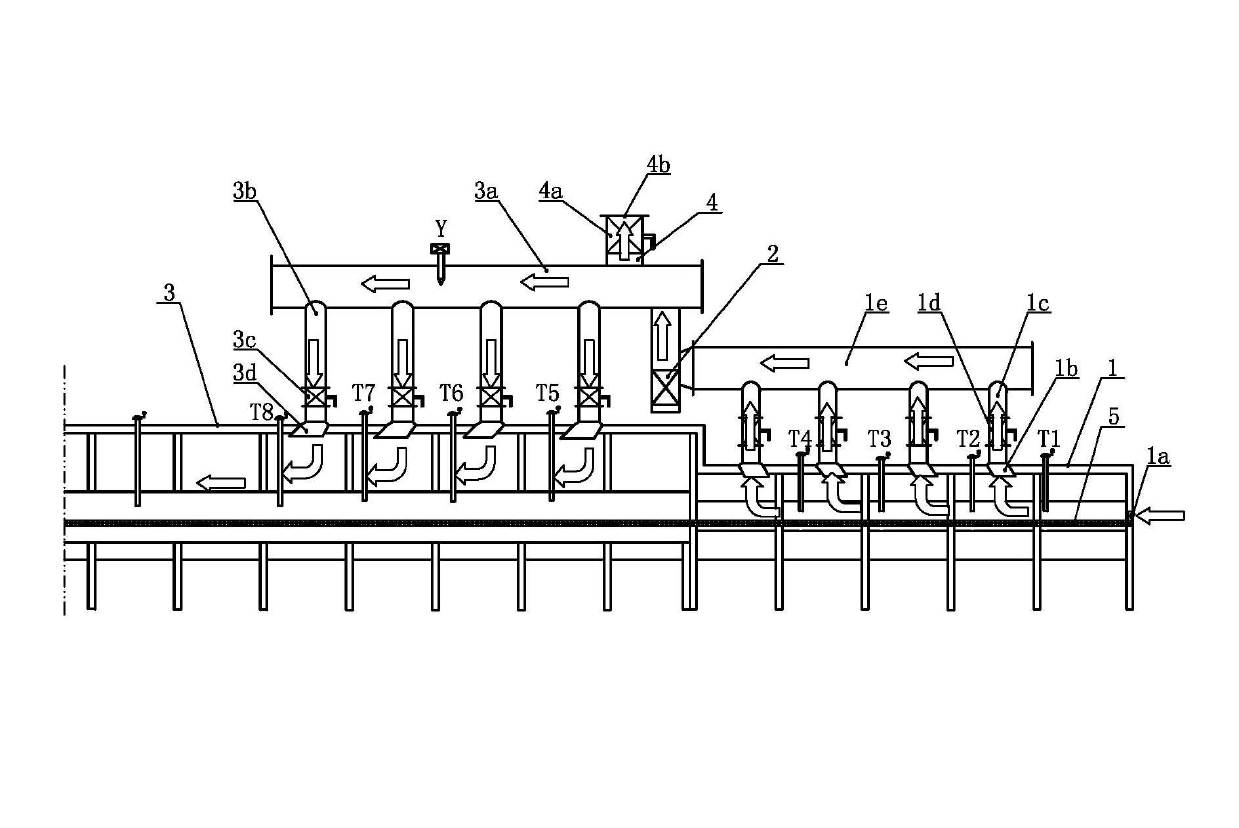

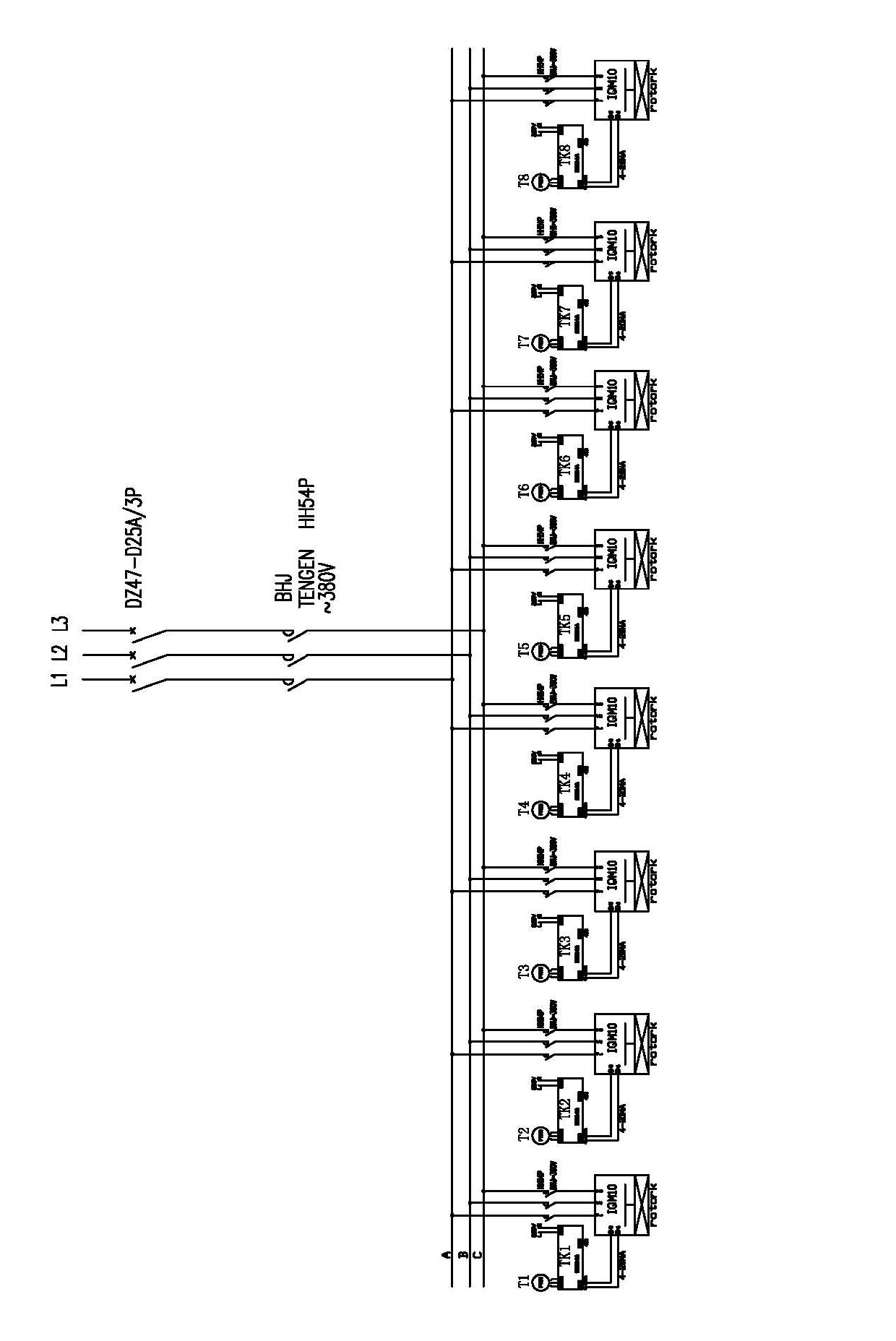

[0019] Such as figure 1 As shown, the flow field control system in the mesh belt kiln kiln of the present invention includes the high box 3 of the cooling section of the mesh belt kiln and the low box 1 of the cooling section of the mesh belt kiln, and the mesh belt 5 is located in the middle of the height direction of the high box 3 of the cooling section of the mesh belt kiln The lower box 1 of the cooling section of the mesh belt kiln extends horizontally, and the mesh belt 5 is tiled with a denitrification catalyst. The lower end of the tail air inlet 1a is flush with the mesh belt 5, and the top wall of the low box 1 of the mesh belt kiln cooling section is provided with a plurality of low box suction hoods 1b, and each low box suction hood 1b is respectively located in the mesh belt kiln cooling section The middle part of the width direction of the low box is evenly distributed along the length direction of the low box in the cooling section of the mesh belt kiln. Tilt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com