Selection method of pipe plugging for shell-sand-tube heat exchanger

A shell-and-tube heat exchanger and heat exchange tube technology, applied in heat exchange equipment, lighting and heating equipment, and by measuring the acceleration and deceleration rates of fluids, etc. and other problems, to achieve the effect of reducing the number of temporary parking, improving the economic benefits of the enterprise, and reducing the hidden danger of accidents in the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

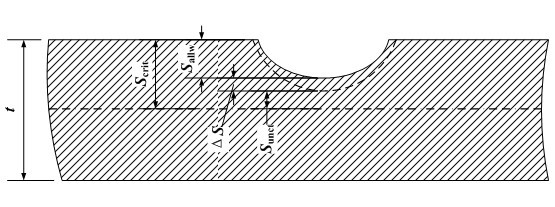

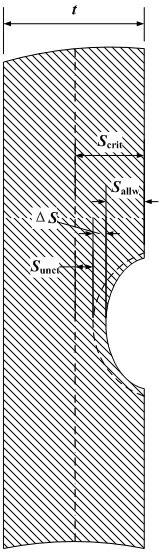

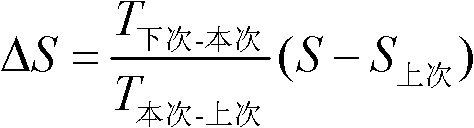

[0033] The heat exchange tube wall thickness t and critical failure defect size S of the present invention crit , the current maximum allowable defect size S allw , defect growth size ΔS and detection uncertainty S unct relative relationship between figure 1 shown.

[0034] In order to achieve the above purpose, the technical solution adopted by the present invention is: when the heat exchanger is overhauled this time, the leaked heat exchange tubes are first selected according to the existing heat exchanger hydraulic test method, and then through non-destructive testing and integrity evaluation Technology selects the heat exchange tubes that may leak during the next operation cycle, and the sum of the two parts ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap