Automatic imaging detection analysis processing system for macroscopic test

A technology of imaging detection, analysis and processing, applied in the direction of optical testing flaws/defects, etc., to achieve the effect of improving steel quality, improving detection speed, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

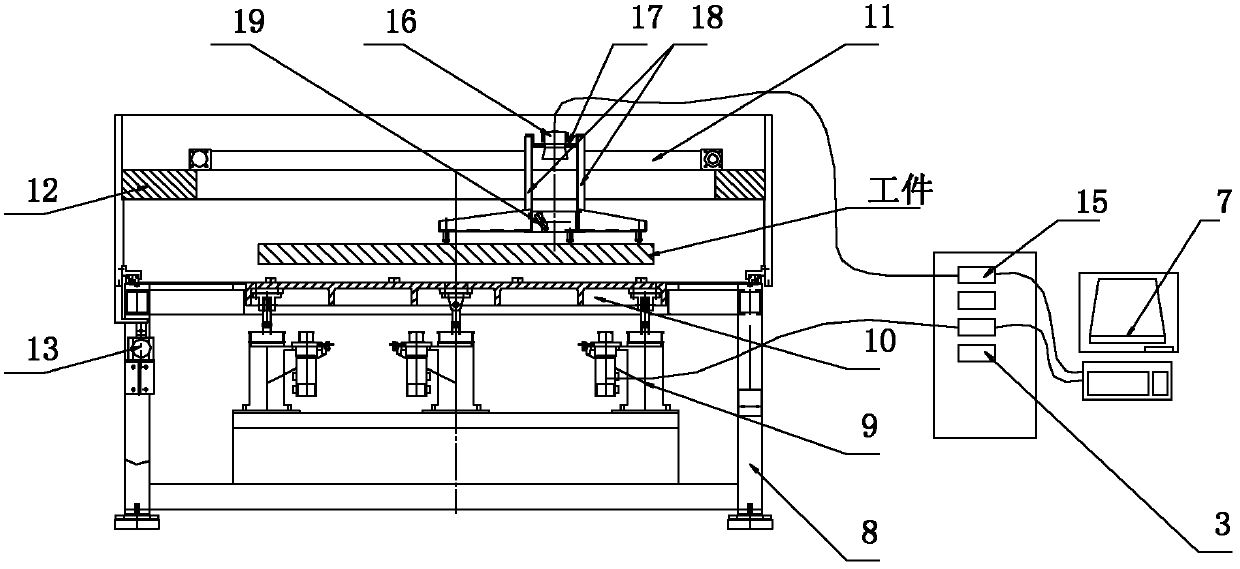

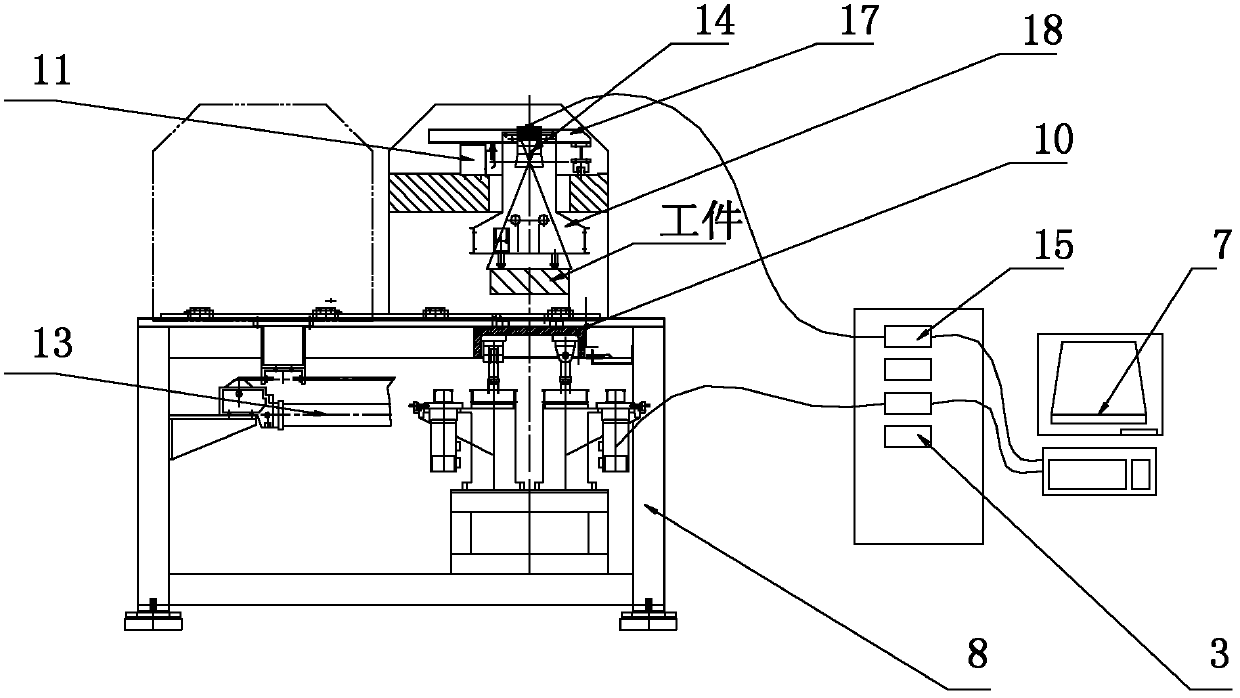

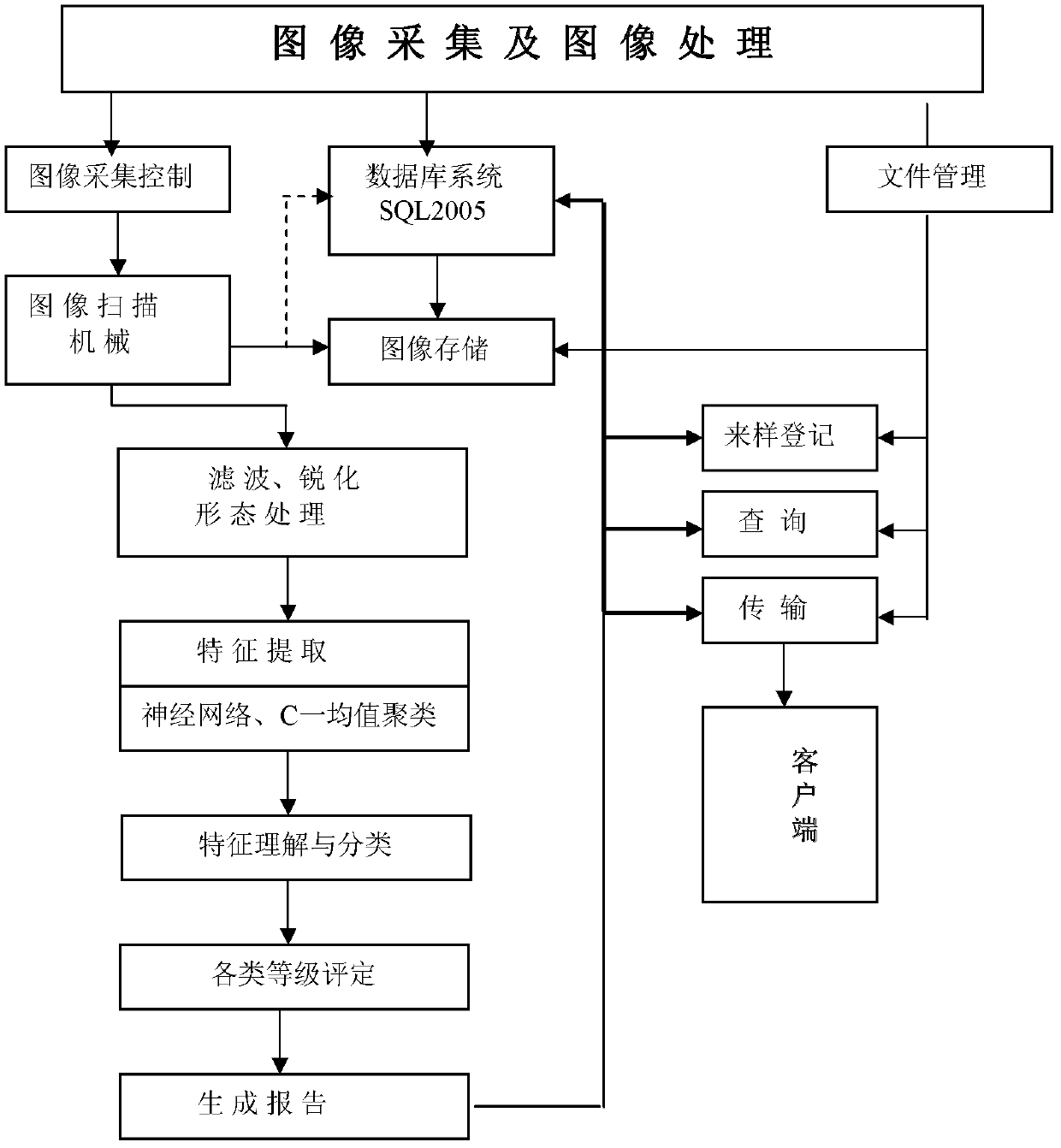

[0018] A low magnification test automatic imaging detection analysis processing system, such as figure 1 and figure 2 As shown, including: workpiece leveling system, camera motion system, multi-axis CNC drive system 3, image information acquisition and processing system, surface quality analysis and automatic rating software system, and image storage management browsing report generation system;

[0019] The workpiece leveling system is installed on the inner front side of the frame 8, and consists of three servo axes 9 and a platform 10. The three servo axes 9 drive the platform 10 for lifting adjustment, and drive the workpiece placed on the platform 10 to make the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com