Device and method for converting circular motion

A kind of arc motion and motion conversion technology, applied in transmission, medical science, brushes, etc., can solve the problems of difficult application, low efficiency, etc., and achieve the effect of stabilizing the driving relationship and solving the load and fault.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

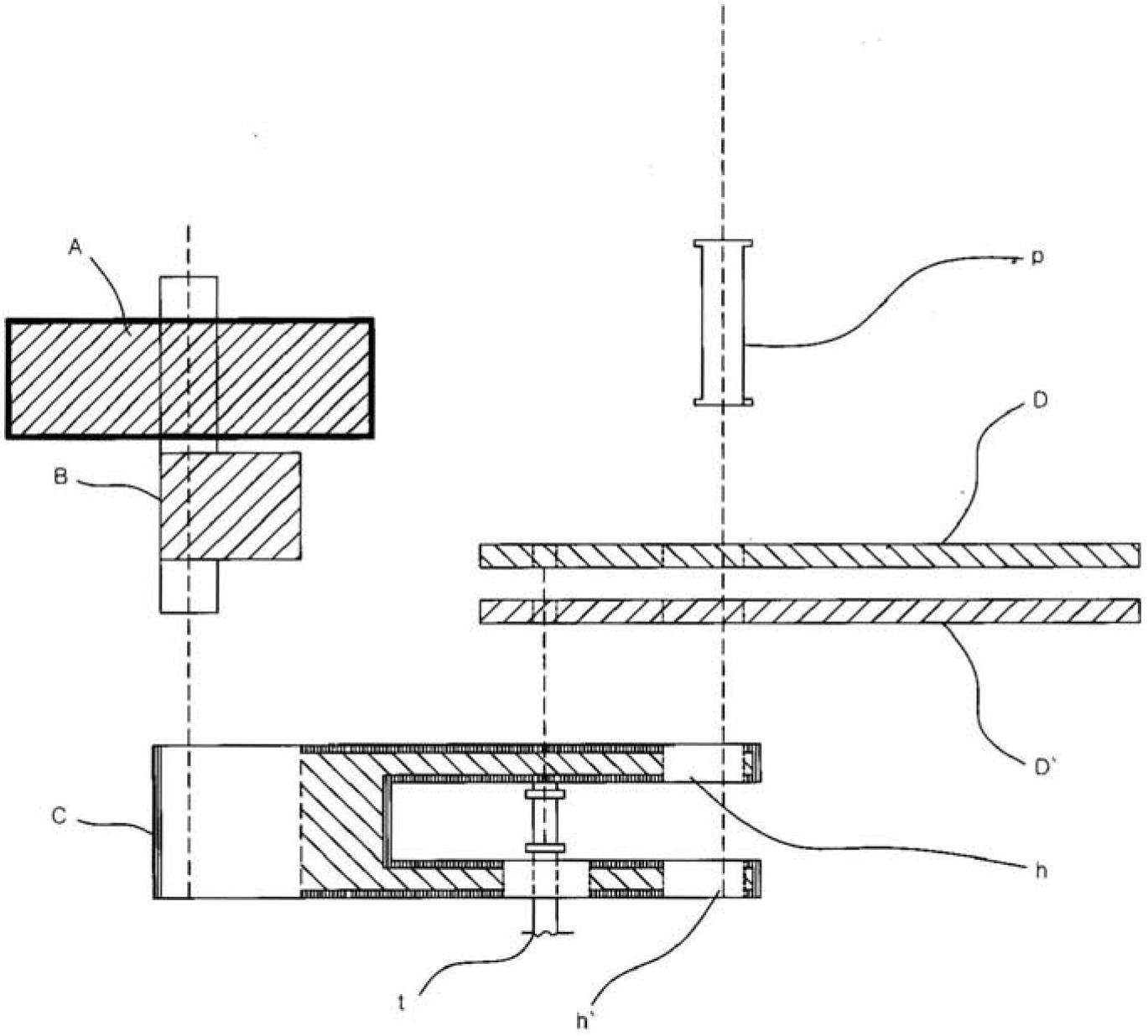

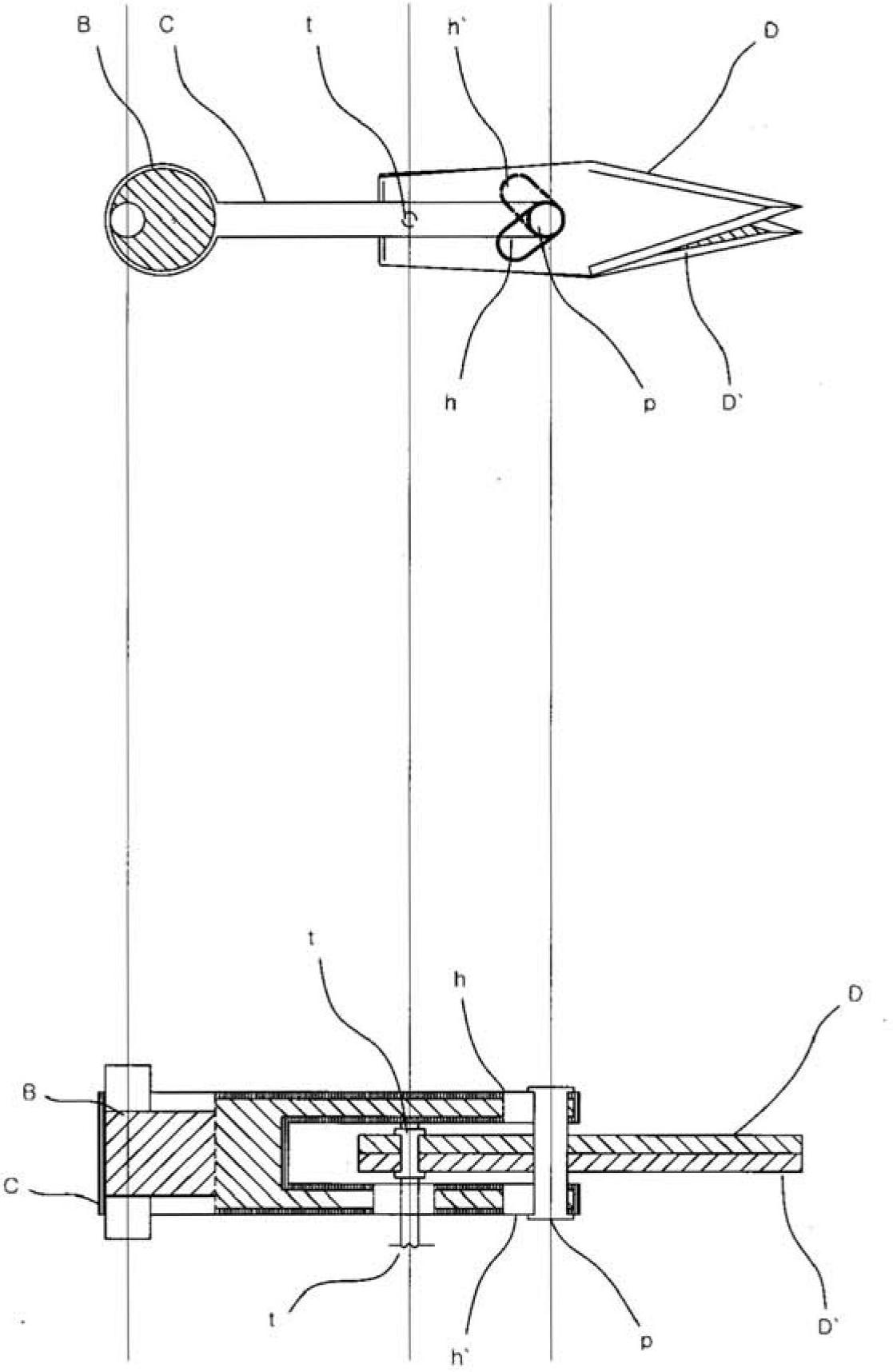

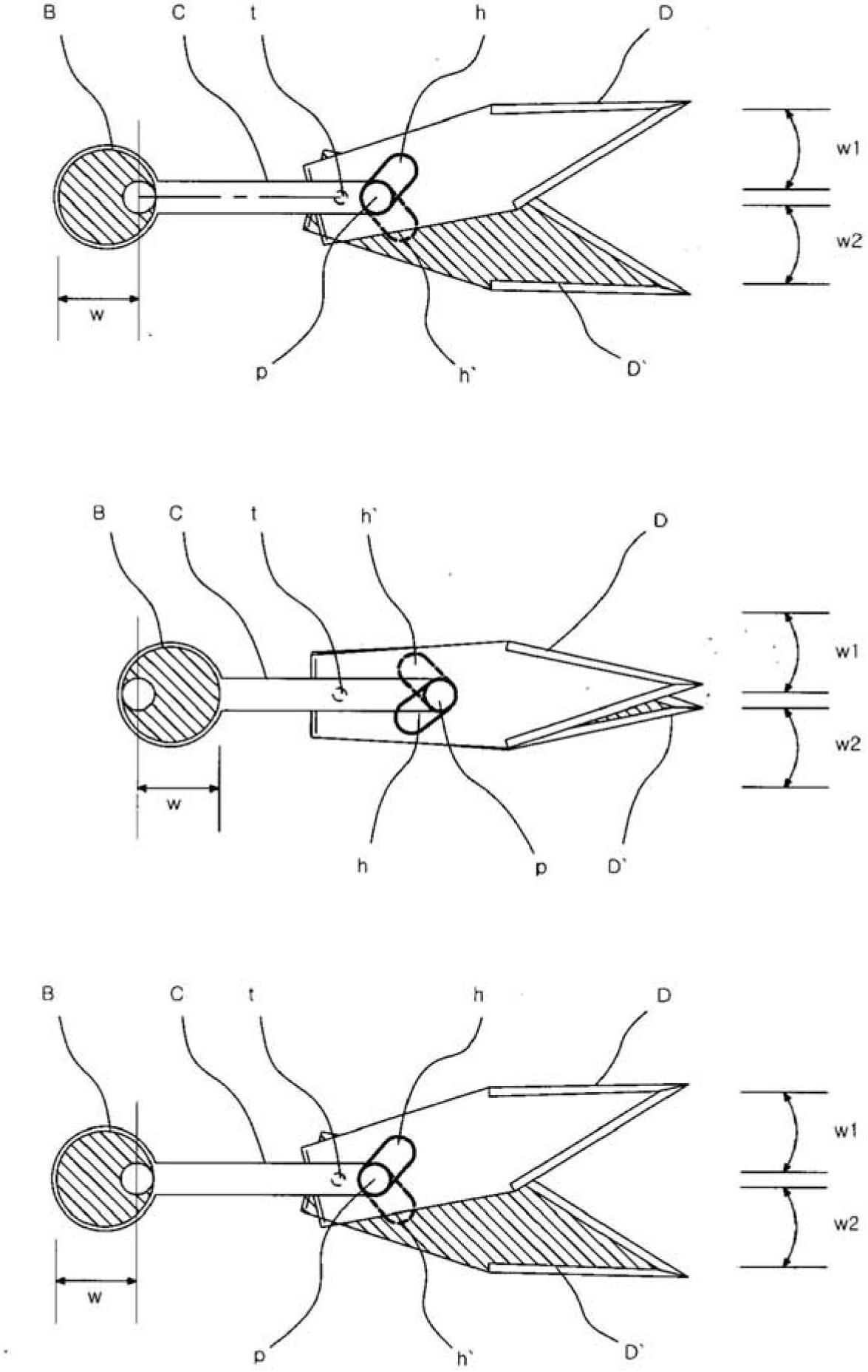

[0025] When the rotary power is generated by an internal combustion engine, a motor, etc. as a general rotary power generating device, the power is transmitted through various gears, cams, shafts, etc. In the mechanical device used to convert the direction of this rotary motion, the eccentric cam is often used to convert the direction of motion.

[0026] As briefly explained in the previous prior art, the above-mentioned method is applied to the motion conversion of various mechanical devices, so in devices that use eccentric cams to convert rotational motion into other motion directions, it is a fact that generally It is used for one conversion, that is, converting eccentric rotation motion into motion in various directions.

[0027] In the present invention, such motion can be applied to various mechanical devices in order to improve efficiency and stability in use in the device and method for converting eccentric rotary motion into arc motion. Use, in the power unit that p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com