Sandwich structure having arrestment feature and method of making the same

A sandwich structure and component technology, applied in the direction of manufacturing tools, layered products, transportation and packaging, etc., can solve the problems of inconsistent propagation, expensive manufacturing and assembly of substructures, increased weight of sandwich structures, etc., to improve fracture and structural toughness, Improved strength, the effect of improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

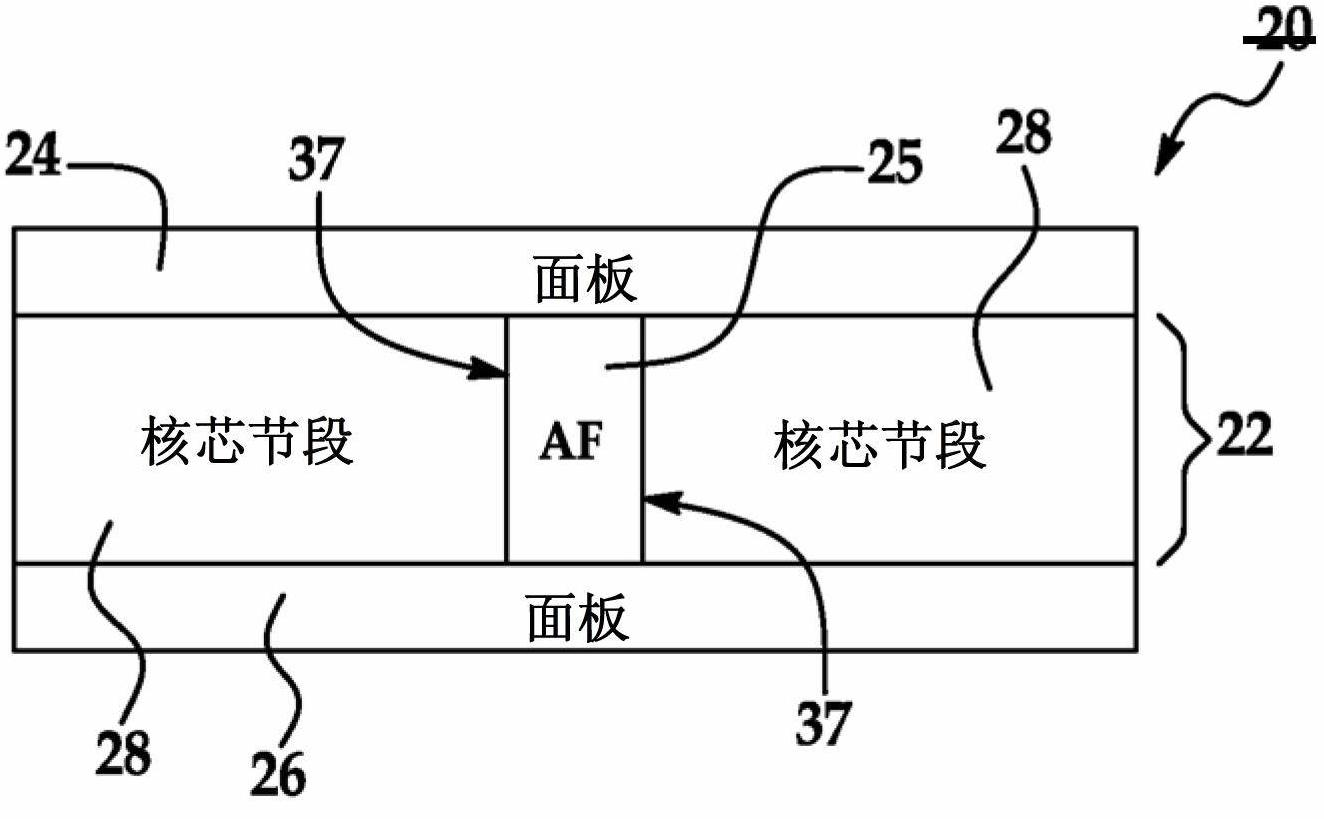

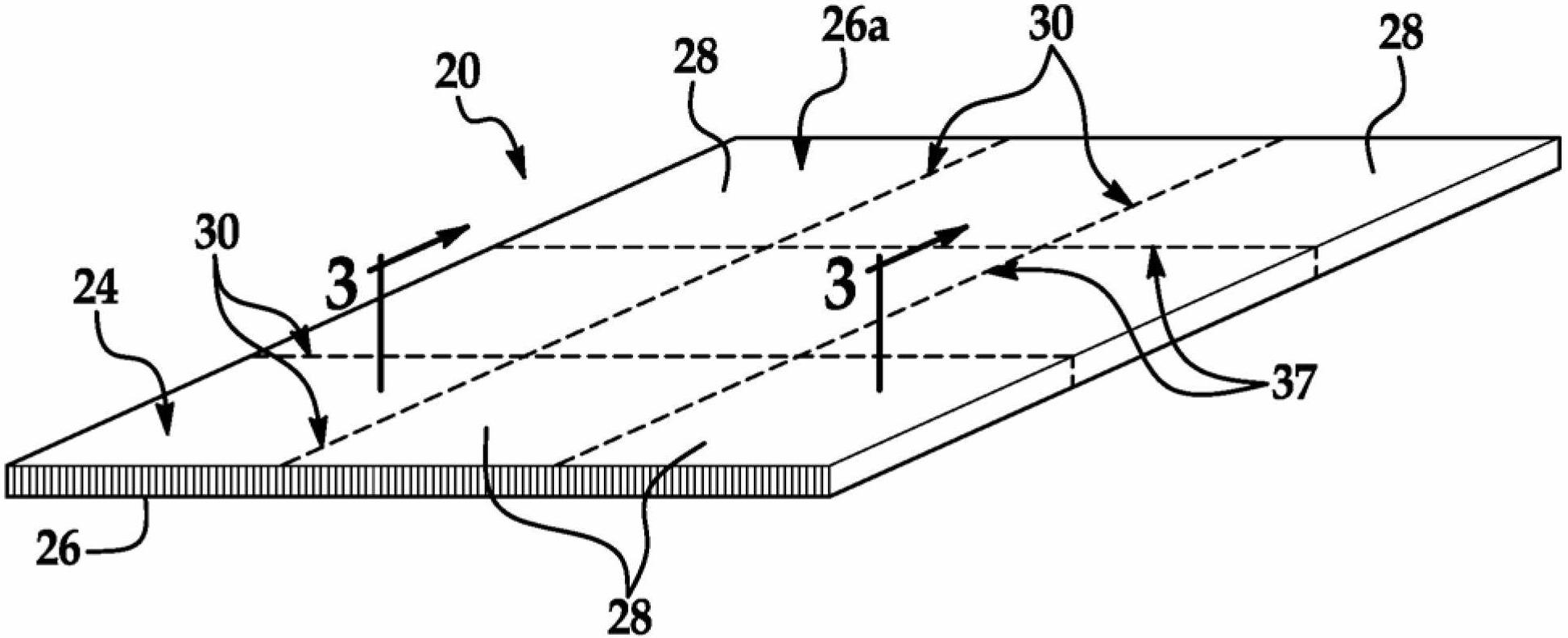

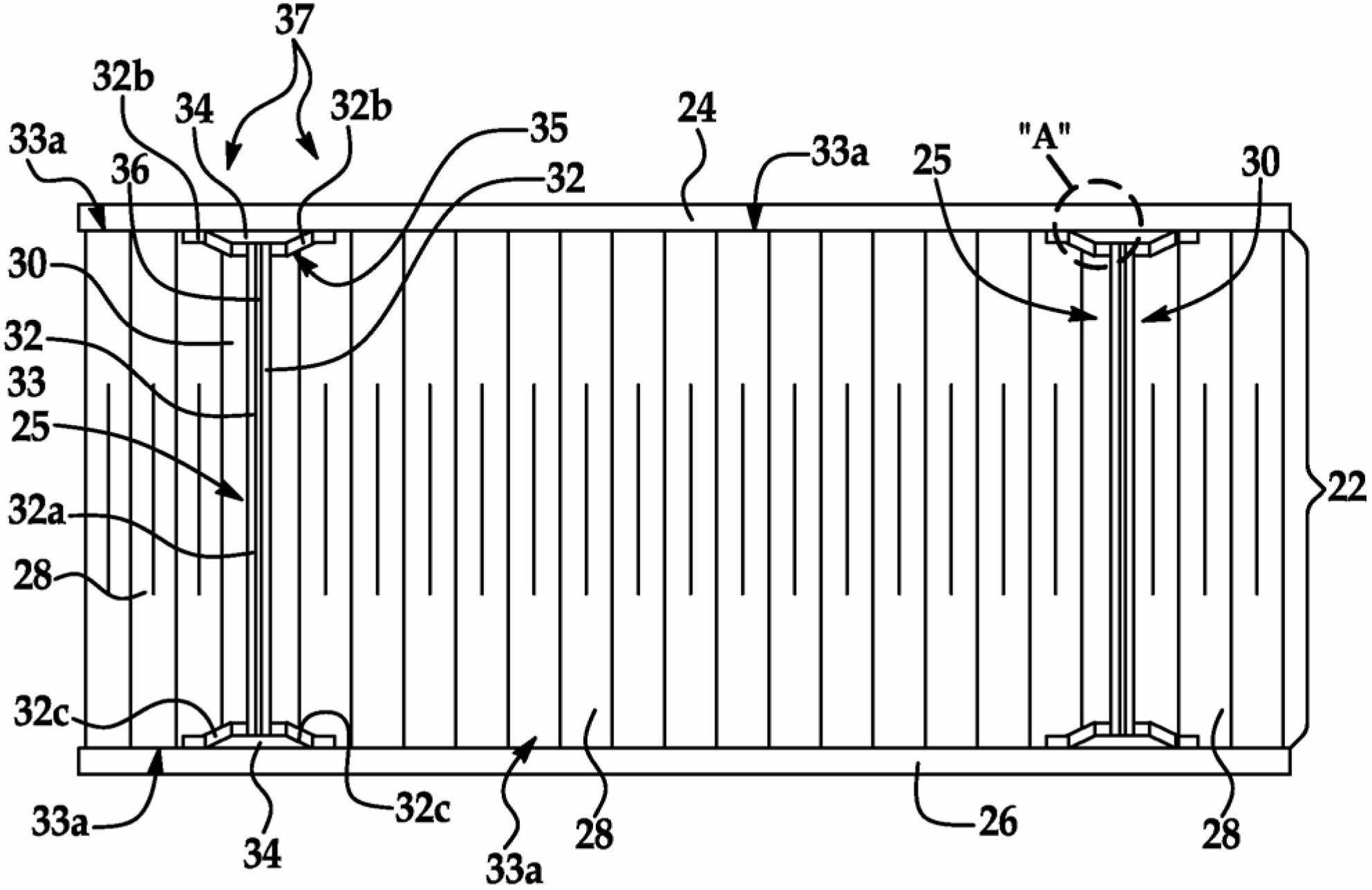

[0061] first reference figure 1 with figure 2 , the disclosed embodiments relate to a composite sandwich structure 20 comprising a segmented core 22 sandwiched between first and second face sheets 24, 26 and secured thereto. Core 22 includes a plurality of core segments 28 that are spliced together along a common edge 37 thereof to form joint 30 . In the example shown, the joints 30 extend substantially orthogonally, although other geometries are possible. Also, while sandwich structure 20 is shown as being substantially flat, it may include curvature and various contours (not shown) to suit a particular application.

[0062] The sandwich structure 20 includes, along the joint 30 , a blocking member 25 disposed between two adjacent segments of the core segment 28 and disposed between the face sheets 24 , 26 . As described in more detail below, the blocking member 25 may be used to block the propagation of one or more local inconsistencies (not shown) in the sandwich stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com