Coagulating sedimentation separator

A technology of coagulation sedimentation and separator, which is applied in the field of water treatment, can solve the problems of large fluctuation in water quality, high intensity of operation and management, unreasonable dosing of chemicals, etc., and achieves good effluent water quality, saves electricity consumption, and improves the utilization rate of chemicals. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

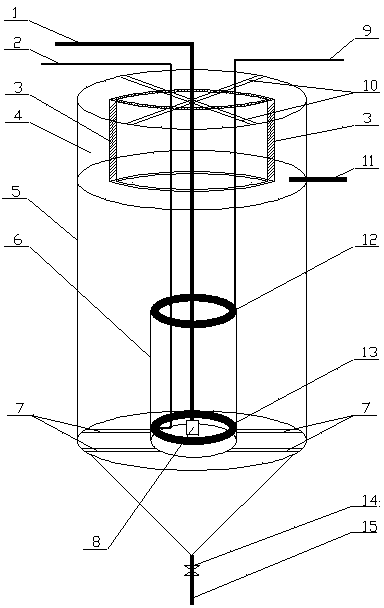

[0024] see figure 1 , an embodiment of a coagulation-sedimentation separator of the present invention mainly includes a housing 5, a water outlet tank 4 in the housing 5, a water outlet pipe 11 connected to the water outlet tank 4, a dosing device 12, 13, and a dosing device The dosing pipes 9 and 2 connected by 12 and 13, the water inlet pipe 1, and the mud discharge pipe 15 provided at the bottom of the casing 5.

[0025] The shell 5 is made of a steel plate of a certain thickness (such as: carbon steel plus glass fiber reinforced plastic or stainless steel) into a circular cylinder, the upper part is a cylinder, the lower part is a cone, and is supported by a base. An annular water outlet tank 4 is arranged on the upper part of the cylinder part in the housing 5, the outer ring groove wall of the water outlet groove 4 is the side wall of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com