Rapid clamping drive plate

A chuck and fast technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of many hours of work and high labor intensity, and achieve the effect of low labor intensity, reasonable structure and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

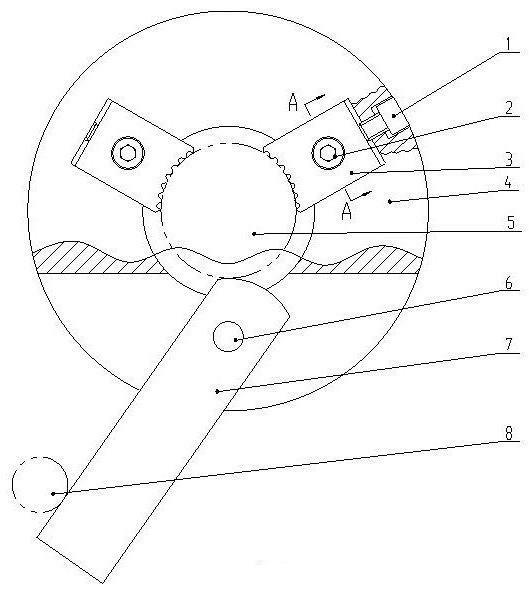

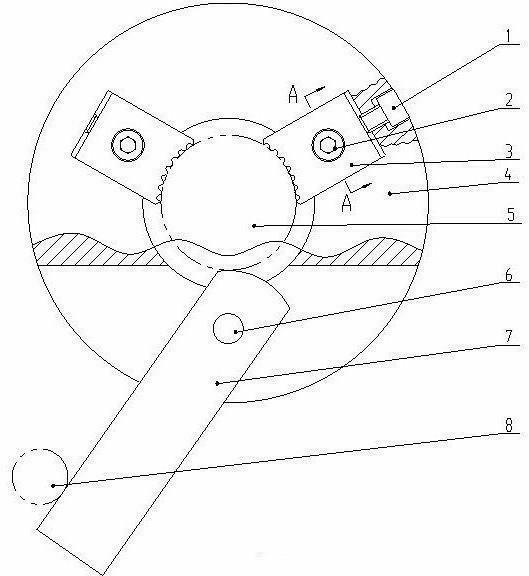

[0013] from figure 1 with figure 2 It can be seen that a quick clamping dial is provided with a chuck body 4, two claws 3, and an eccentric pressure rod 7. The chuck body 4 is axially provided with a round hole for fitting a workpiece 5. When in use, First, the chuck body 4 is inserted into the outer circle of the workpiece 5 .

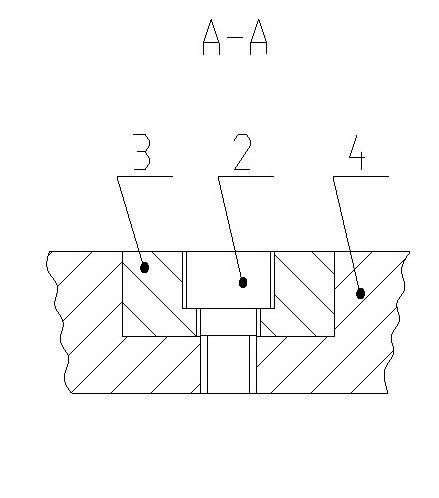

[0014] Two rectangular grooves are symmetrically arranged on the end surface of the chuck body 4 of the present invention, and the middle part corresponding to the rectangular grooves on the chuck body 4 is provided with a screw hole, and the middle part of the claw 3 is provided with a counterbore. Cooperating with the screw hole provided in the middle of the chuck body 4, the two claws 3 are respectively installed in the rectangular grooves of the chuck body 4, and the compression screw 2 is compressed and fixed. Such as figure 2 shown. The front end surface of the claw 3 protrudes radially from the circumferential surface of the circular hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com