Parallel mechanism of four-degree-of-freedom dual acting platform

A technology with double-moving platforms and degrees of freedom, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large size, uncompact structure, and increased weight of the moving platform, so as to improve the rigidity and stability, and the overall Superior compact structure and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content and features of the present invention, a detailed description is given as follows in conjunction with the drawings and embodiments:

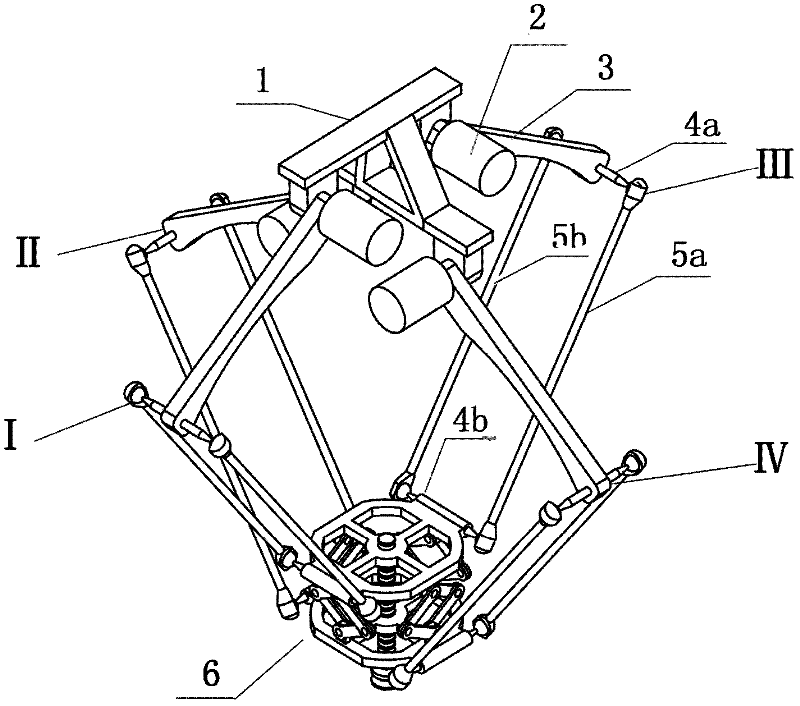

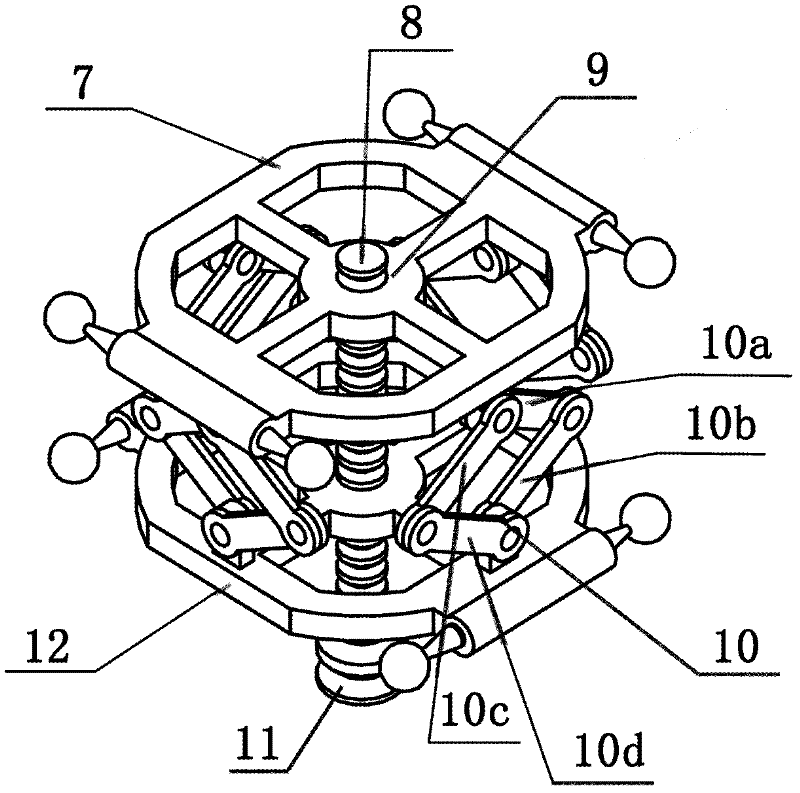

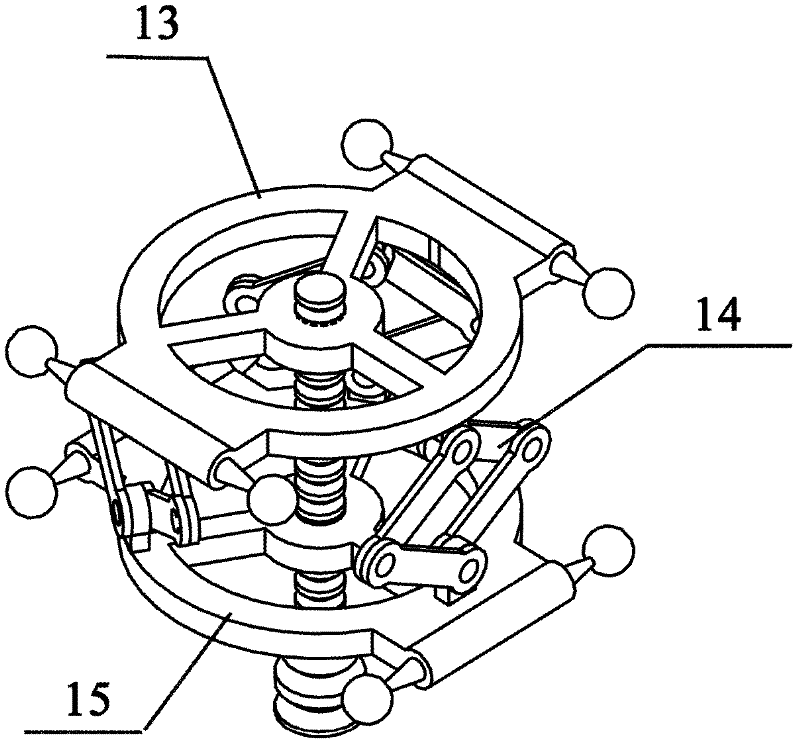

[0018] The embodiment structure of a four-degree-of-freedom parallel mechanism proposed by the present invention, such as figure 1 As shown, it includes a fixed platform 1, a moving platform 6 composed of an upper moving platform and a lower moving platform parallel to each other, a connecting mechanism connected to the upper and lower moving platforms, a rotating mechanism, and an end effector 11 ( figure 2 ), and the first branch I, the second branch II, the third branch III, and the fourth branch IV connecting the fixed platform 1 and the moving platform 6, and the four branches are respectively placed on the fixed platform 1 and the front, rear, left, and right of the outer periphery of the moving platform 6; the four branch chains have the same structure, all including the active link 3, the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com