Fluid Driven Spherical Robot

A spherical robot, fluid-driven technology, applied in the electromechanical field, can solve the problems of difficult engineering implementation, low practicability, complex structure, etc., and achieve the effect of no transmission loss, compact structure, and simplified driving device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

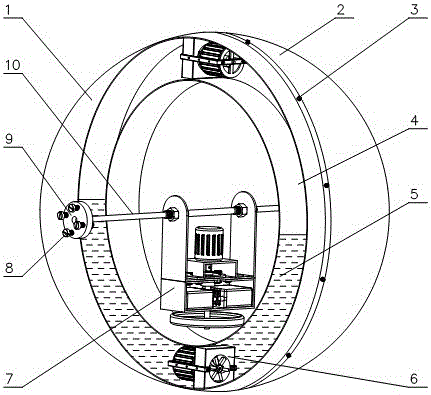

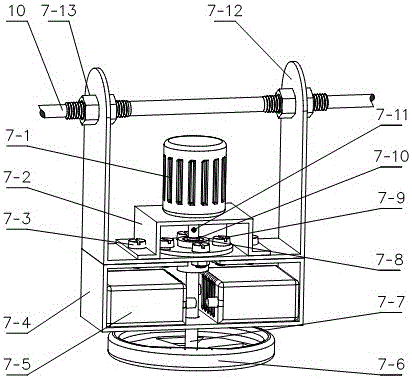

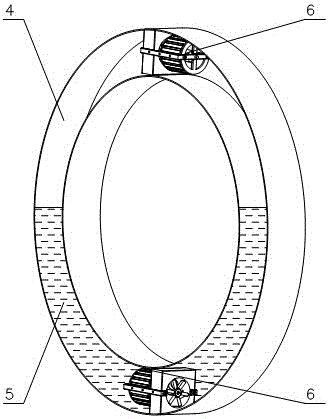

[0026] Such as figure 1 , 2 As shown, an embodiment of the present invention is: a fluid-driven omnidirectional motion spherical robot device, which mainly includes a left hemispherical shell 1, a right hemispherical shell 2, a square annular sealed container 4, an axial flow device 6, an internal drive rotation mechanism 7, The main shaft 10; the left and right hemispherical shells are fastened by screws 3, the square ring-shaped sealed container 4 is located inside the spherical shell, the outer ring surface of the container is concentric with the spherical surface of the spherical shell, and the fluid (usually liquid) is contained inside the container, and the volume of the fluid is equal to the volume of the container 1 / 2, two axial flow devices 6 are symmetrically installed inside the square annular sealed container, and the axial flow device drives the liquid 5 to flow in the square annular sealed container 4, thereby changing the center of mass of the spherical robot, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com