Balance sliding device of block material loader

A technology of sliding device and loader, applied in the direction of lifting device, etc., can solve the problems of inconvenient use, poor maneuverability, inflexible movement, etc., and achieve the effect of expanding the scope of use, compact structure and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

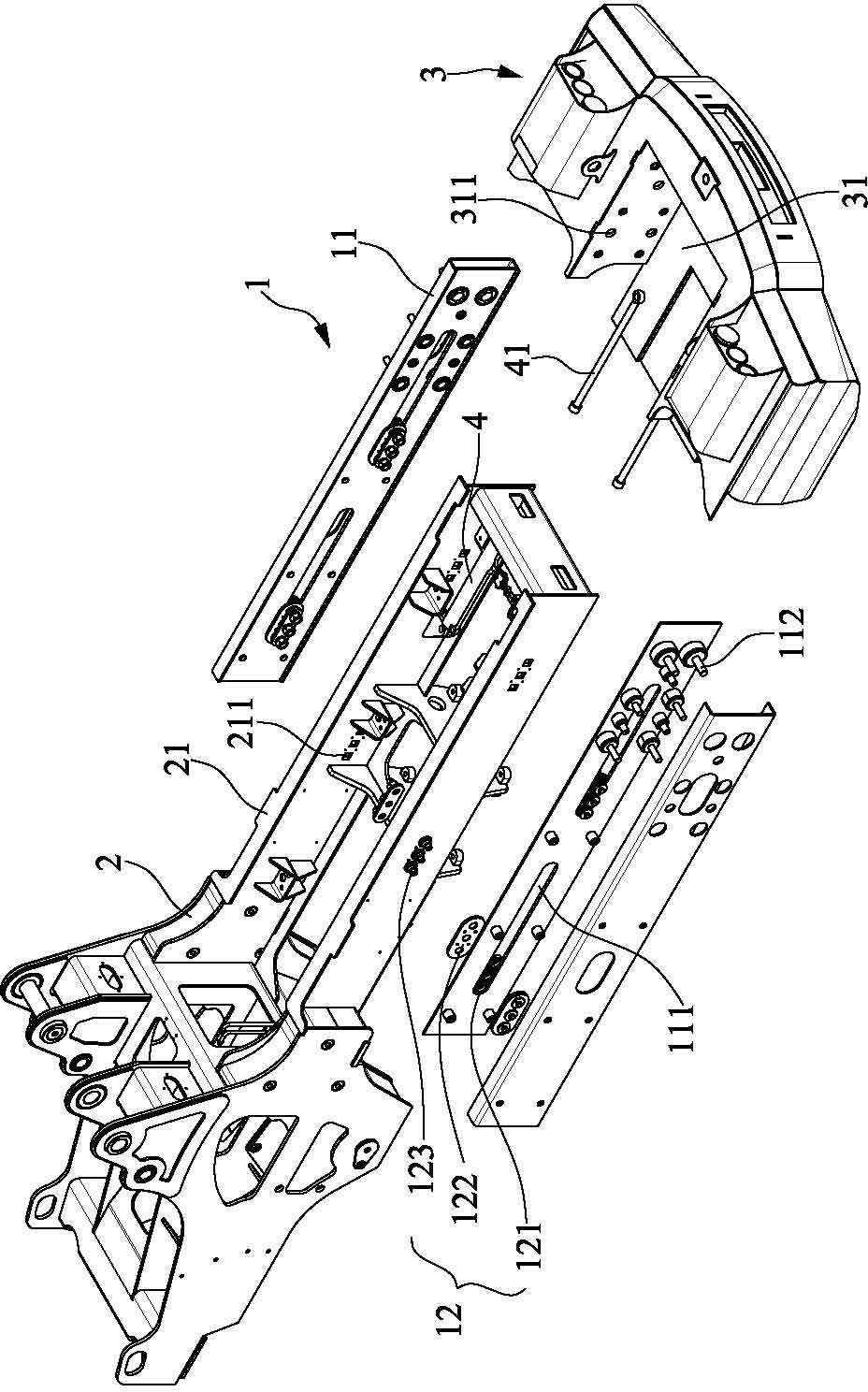

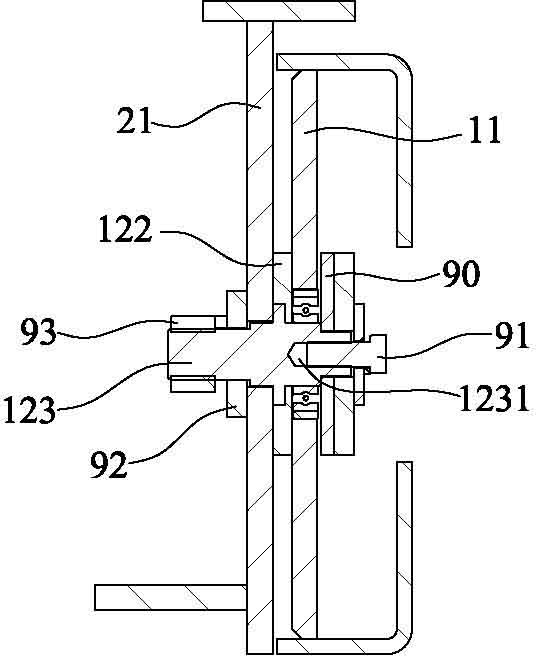

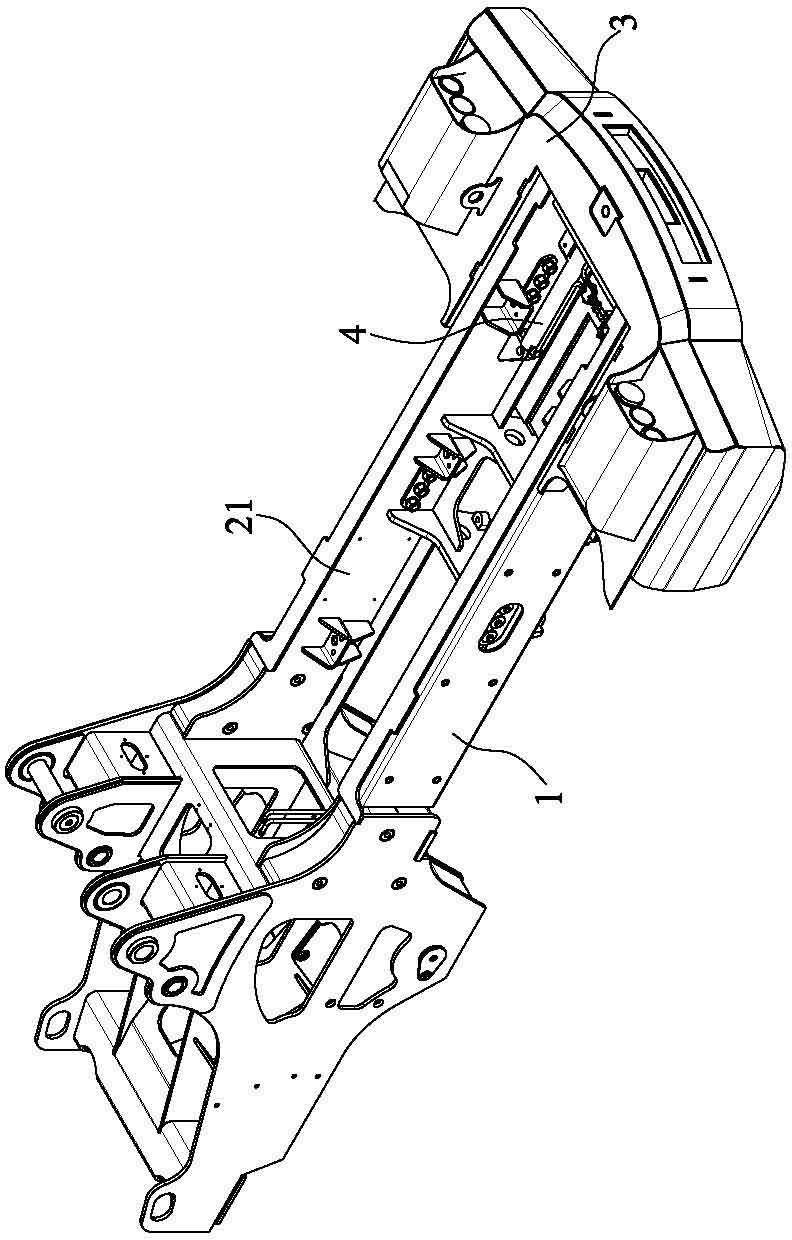

[0040] Such as figure 1 As shown, a balance sliding device for a block loader disclosed by the present invention includes an inner plate 21, a balance weight slide plate group 1, a balance weight 3, a balance weight oil cylinder 4, a pressure sensor 5 and a control system 6; the inner plate 21 is installed On the frame 2, the balance weight slide set 1 is slid on the inner plate 21 of the frame 2, and the balance weight 3 is connected with the inner plate 21 of the frame 2 through the balance weight slide set 1; the balance weight cylinder 4 is installed on the frame 2, the cylinder rod 41 of the balance weight cylinder 4 is fixed on the balance weight 3, so that the balance weight cylinder 4 can control the balance weight 3 to move.

[0041] A pressure sensor 5 is also installed on the vehicle frame 2, so that the weight change of the goods c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com