Preparation method of pyrazolone/polymer composite photochromic film

A technology of pyrazolone and polymer is applied in the field of preparation of pyrazolone/polymer composite photochromic film, can solve problems such as inconvenience of manufacture, and achieve the effects of low cost, uniform texture and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] At room temperature, under the condition of magnetic stirring, slowly add 0.25 g of HPMC white powder into 20 ml of distilled water, and keep stirring to fully dissolve HPMC to form a clear solution. Then, under the condition of avoiding light, slowly add 0.05 g of DP3BrBP-PSC white powder into the clear solution, and continue to stir for 3 hours, so that DP3BrBP-PSC is well dispersed in the clear solution to obtain a co-suspension, After defoaming by standing in the dark, the blended suspension was slowly poured into a clean glass tank, and dried overnight at room temperature in the dark to obtain a pyrazolone / polymer composite photochromic film. The composite film has good photochromic properties, and it turns from white to yellow after being irradiated with 365nm ultraviolet light.

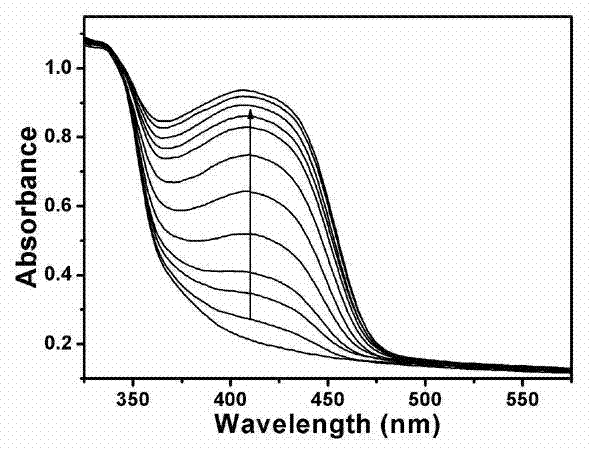

[0017] The above-mentioned composite film has good photochromic performance, and the ultraviolet absorption spectrum of the composite film is shown as follows: figure 1 As shown, it is ...

Embodiment 2

[0019] At 60°C, under the condition of magnetic stirring, slowly add 3 grams of PVA white particles into 20 ml of distilled water, and stir for 1 hour to fully dissolve the PVA and form a clear solution. Then, 0.06 g of DP3BrBP-PSC white powder was slowly added to the clear solution at room temperature and protected from light, and the stirring was continued for 5 hours, so that DP3BrBP-PSC was well dispersed in the clear solution to obtain a co-suspension, After defoaming by standing in the dark, the blended suspension was slowly poured into a clean glass tank, and dried overnight at room temperature in the dark to obtain a pyrazolone / polymer composite photochromic film. The composite film has good photochromic properties, and it turns from white to yellow after being irradiated with 365nm ultraviolet light.

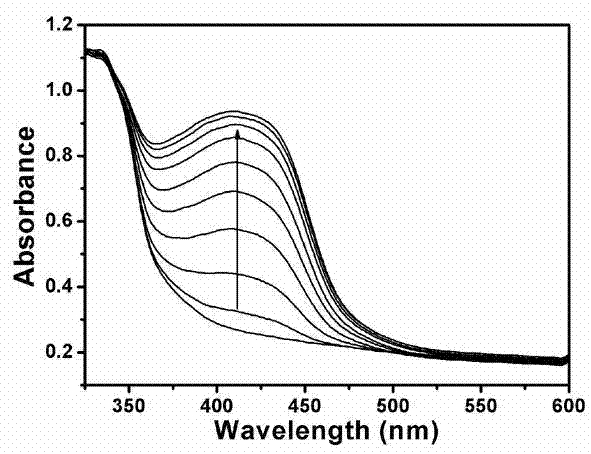

[0020] After irradiating with 365nm ultraviolet light, the ultraviolet absorption spectrum of the composite film is as follows: image 3 As shown, it is found that a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com