Novel roadbed side slope building protecting method and precast concrete blocks therefor

A prefabricated concrete and concrete technology, applied in roads, roads, buildings, etc., can solve the problems of difficult construction quality control, failure to meet roadbed slope protection, and affect engineering safety and quality, so as to improve stability and safety and ensure slope protection quality And life, shorten the effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

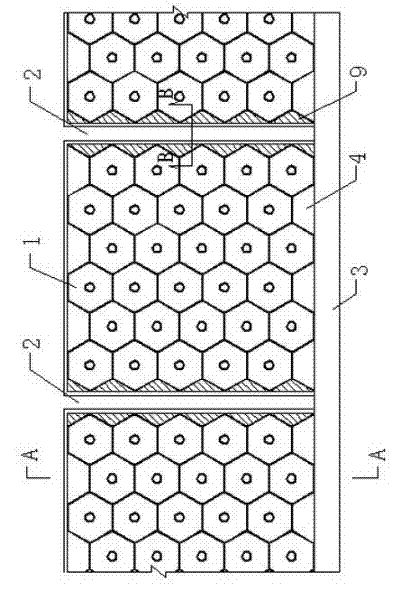

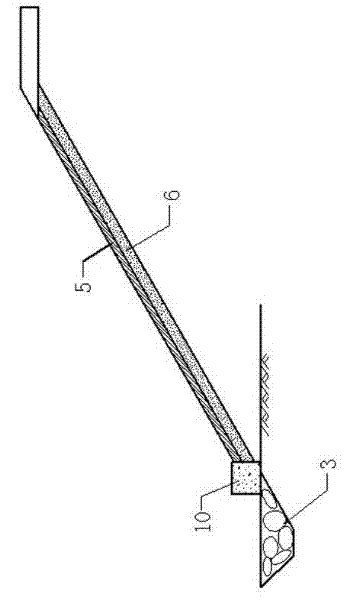

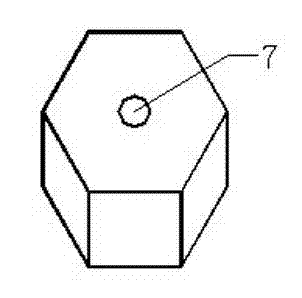

[0025] as attached Figure 1-4 As shown, a new roadbed slope protection method, the slope protection foundation is a stone foundation 3, prefabricated concrete blocks 1 are used to lay along the slope surface, and a U-shaped concrete drainage channel 2 is arranged at intervals along the line direction. The prefabricated concrete block 1 is a regular hexagonal prism structure, which is a C25 plain concrete prefabricated block. The hexagonal prism is provided with drainage holes 7 passing through the upper and lower surfaces of the cylinder. The drainage holes 7 are used to meet the requirements of water seepage from the inside of the subgrade. The shape of the drainage hole 7 can be a round hole or an oval hole or a triangular hole or a rectangular hole or other shapes. The drainage hole 7 is preferably arranged in the middle of the prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com