Carrier for highway flyover

A technology for overpasses and carriers, applied in the field of reloading equipment, can solve problems such as high manufacturing costs, comprehensive utilization of unfavorable sites, and unusable space in the middle of the runner, so as to achieve the effect of improving utilization rate and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

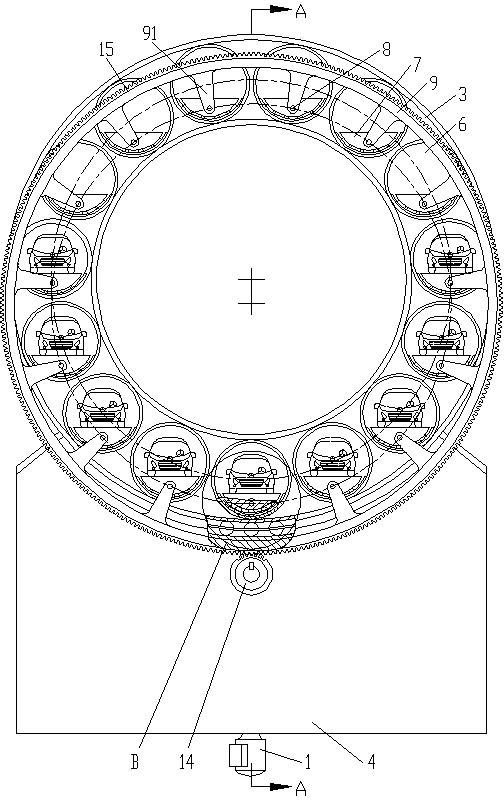

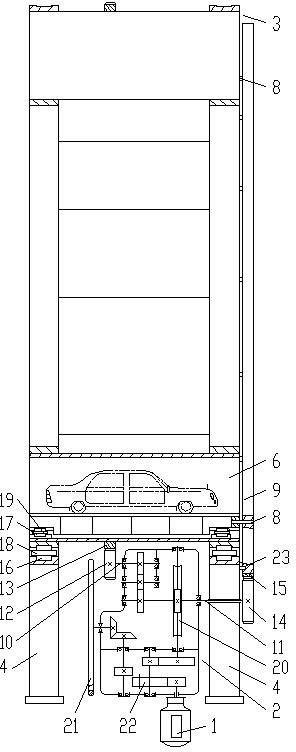

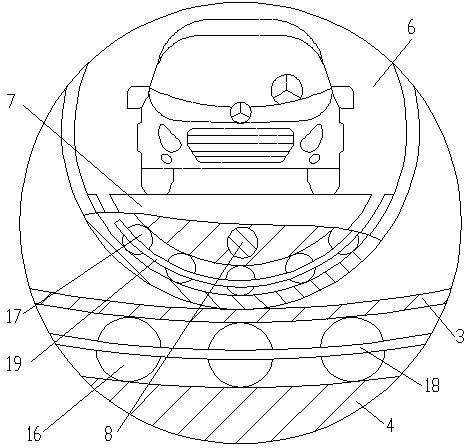

[0024] Example 1 see figure 1 , figure 2 , image 3 , Figure 4 , a carrier machine used for highway overpasses, comprising a reducer 2 connected to a drive motor 1, a runner 3 provided with a plurality of bearing compartments, the runner 3 is in a ring structure, and a The base 4, the upper end surface of the base 4 supports the runner 3 and is coaxial with the arc concave surface of the runner 3; 3 A plurality of circular tube holes 6 arranged on the axis, a bearing platform 7 is arranged inside the circular tube hole 6, the lower end of the bearing platform 7 is an arc surface coaxial with the circular tube hole 6, and the bearing platform 7 passes through the circular arc surface at the lower end. The arc surface is rotatably supported on the inner wall of the circular pipe hole 6; one side of the runner 3 is provided with a stop ring 9, the axis of the stop ring 9 is parallel to the axis of the runner 3, and the axes of the stop ring 9 are opposite to each other. ...

Embodiment 2

[0037] Example 2 see Figure 5 , the stop ring 9 is connected with the pin shaft 8 by its annular body part. In order to ensure that the load-bearing bin has enough passage space for vehicles or personnel to enter and exit at the lower end and the upper end, the load-bearing bin is only used for one-way entry or exit when it is in the middle. When vehicles or personnel are selected to enter at the upper end, lower end or middle part, they can exit at the lower end or upper end; when vehicles or personnel are selected to enter from the lower end or upper end, they can exit from the upper end, lower end or middle part.

[0038] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0039] The main application of the present invention will be further elaborated below.

[0040] see Image 6 , a three-dimensional traffic structure for highway crossings, the three-dimensional traffic structure includes a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com