Light plastic-woven inner sticking film air duct

A technology of inner film and plastic weaving, applied in the ventilation of mines/tunnels, mining equipment, layered products, etc., can solve the problems of only garbage disposal, difficult repair, low labor efficiency, etc., to reduce local quality and ventilation. resistance, reducing ventilation energy consumption, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

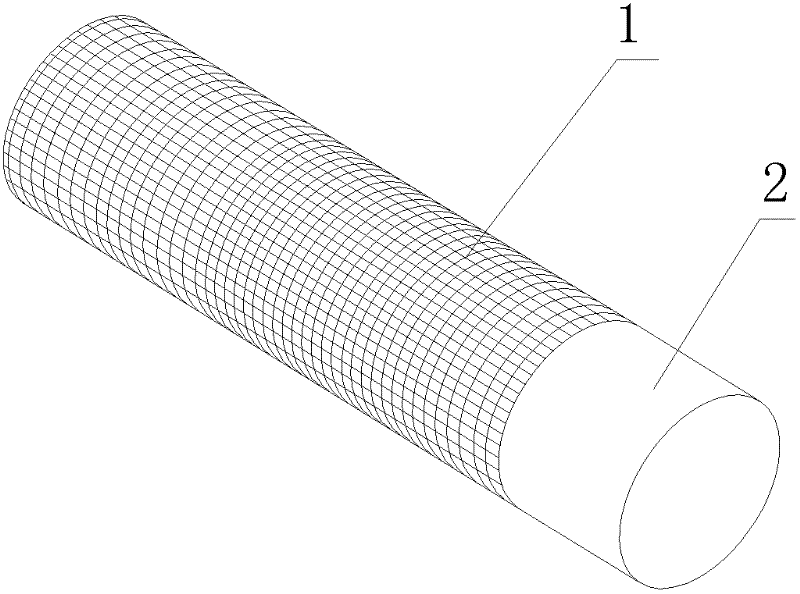

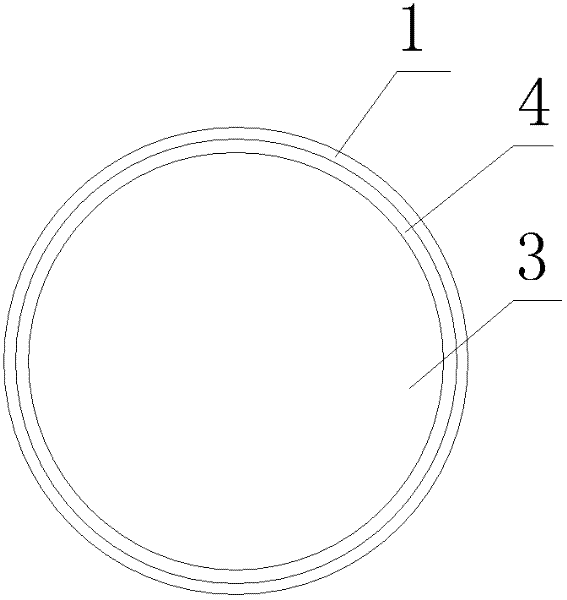

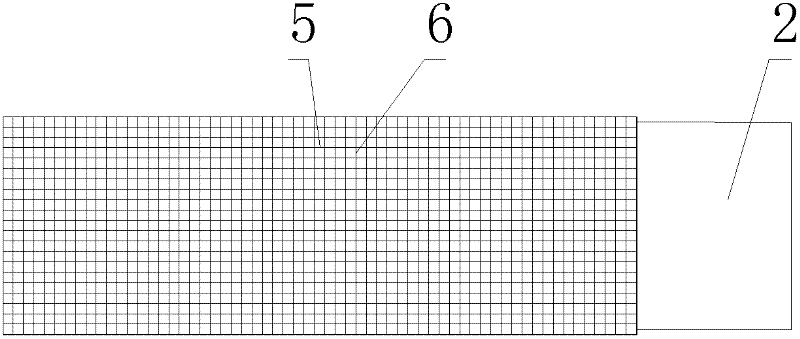

[0014] like figure 1 , figure 2 , a lightweight plastic braided inner mucous membrane air cylinder, which includes a polyethylene plastic mesh braided layer 1 as a skeleton and an inner leakproof layer 2 bonded with the outer polyethylene plastic mesh braided layer 1, wherein , the inner leak-proof layer 2 is a double-layer co-extruded blown film with a thickness of 0.005-0.04mm, and the inner leak-proof layer 2 is composed of a film inner layer 3 and a film outer layer 4 bonded with polyethylene plastic mesh braiding layer 1 The film inner layer 3 is made of LDPE material, the film outer layer 4 is made of EVA, and the polyethylene plastic mesh braided layer 1 is made of PP.

[0015] The bonding temperature of the inner anti-leakage layer 2 is low (70-90° C.), the physical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com