Water-storage-type water heater capable of improving hot water outlet efficiency

A water yield, water storage technology, applied in water heaters, fluid heaters, heat exchanger types, etc., can solve the problems of energy waste, low heat conversion rate, large heat loss, etc., to reduce the flow distance, water outlet rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

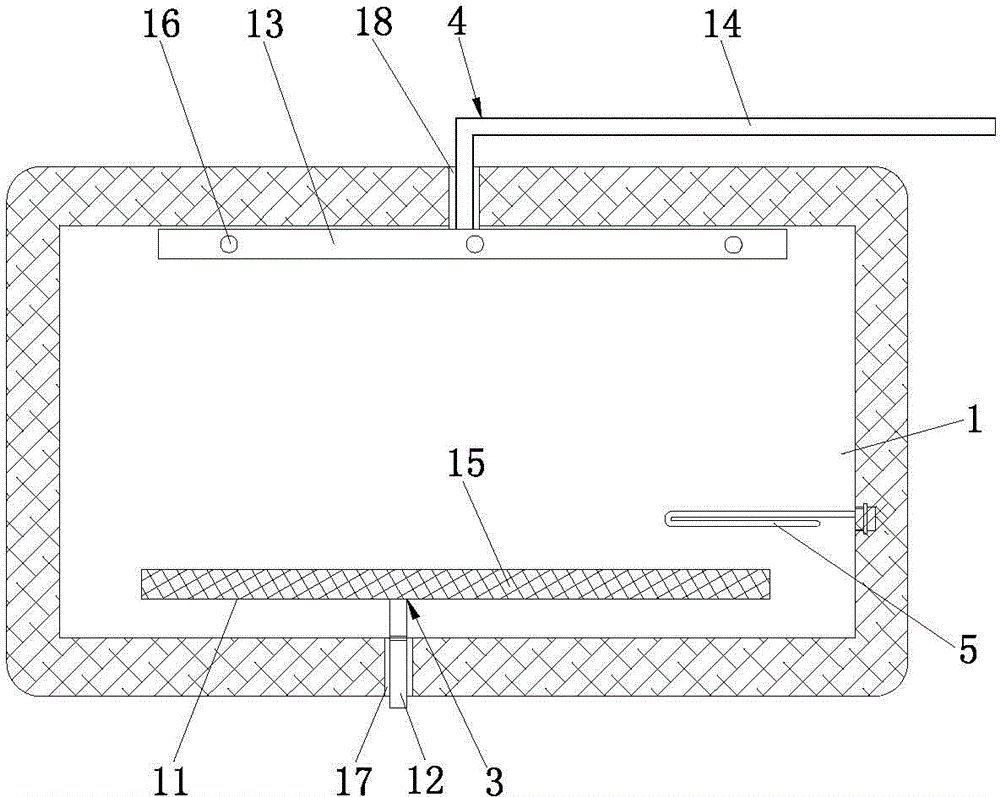

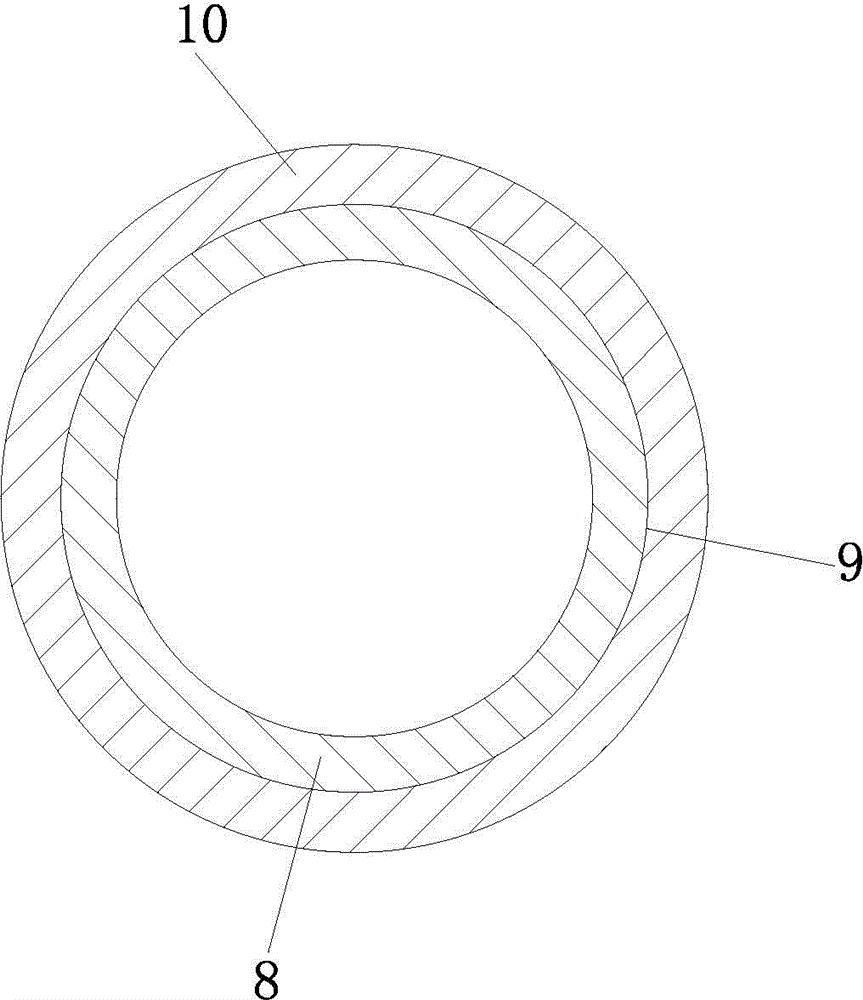

[0029] Embodiment one, such as figure 1 and image 3 As shown, a water storage water heater that can increase the hot water output rate includes a water tank 1, a heating device 5 is provided in the middle of the water tank 1, and a water inlet that allows cold water to enter the water tank 1 at a low speed is provided at the bottom of the water tank 1. Device 3, the top of the water tank 1 is provided with a water outlet device 4 that allows the hot water to flow out evenly in different regions. There is an outer water inlet pipe 12 protruding from the water tank 1, and the inner water inlet pipe 11 is provided with a number of evenly distributed water outlet holes 15, and the water outlet device 4 includes an inner water outlet pipe 13 placed laterally in the water tank 1, so that The inner water outlet pipe 13 is connected with an outer water outlet pipe 14 protruding from the water tank 1, and the inner water outlet pipe 13 includes at least two water absorption holes 16 ...

Embodiment 2

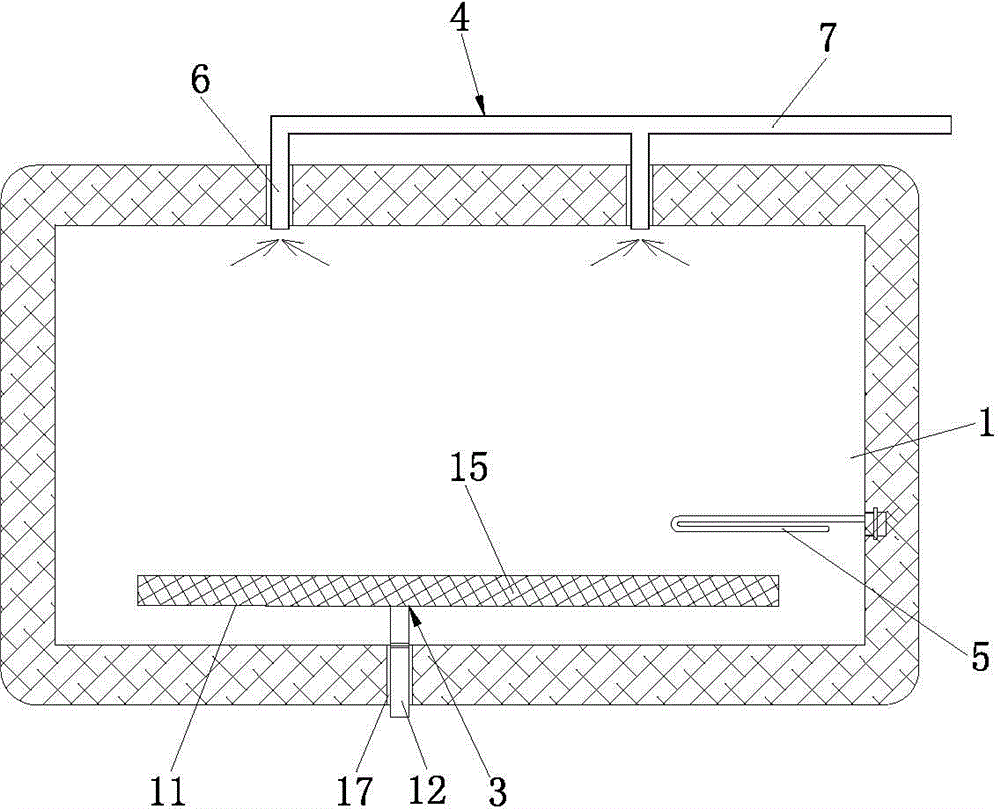

[0034] Embodiment two, such as figure 2 As shown, between the inner water inlet pipe 11 and the outer water inlet pipe 12, a three-layer mesh water outlet hole 15 with a length greater than or equal to 30mm is arranged, and a section of length greater than or equal to The 30mm three-layer mesh water outlet hole 15 can effectively buffer the speed of cold water entering the inner water inlet pipe 11 from the outer water inlet pipe 12 .

[0035] In this embodiment, each water absorption hole 16 is correspondingly provided with a partitioned water outlet pipe 6, and the partitioned water outlet pipe 6 is comprehensively connected with a water outlet main pipe 7, the water outlet main pipe 7 protrudes from the water tank 1, and the water outlet main pipe 7 extends The water tank 1 and the water outlet main pipe 7 can be located in the water tank 1 or outside the water tank 1, and the end of the water outlet main pipe 7 extending out of the water tank 1 can be located on the upper...

Embodiment 3

[0038]Embodiment 3. In this embodiment, when the hot water output rate is not kept warm, when the water output of the water outlet device 4 is 63KG, about 4628.7G per minute, the average inlet water temperature is 23.1°C, and the average outlet water temperature is 66.6 ℃, the highest water outlet temperature is 68.5℃, and the hot water outlet rate can be increased to 92.5%; when the water output of the water outlet device 4 is 65.1KG, about 4628.7G per minute, the average inlet water temperature is 23.1℃, and the average outlet water temperature is 65.6°C, the highest water outlet temperature is 68.6°C, and the hot water output rate can be increased to 93.1%; when the water output of the water outlet device 4 is 62.74KG, about 11865.6G per minute, the average inlet water temperature is 23°C, and the average outlet water temperature is 67.8°C, the highest water outlet temperature is 69.6°C, and the hot water output rate that can be increased is 92.4%; when the water output of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com