Display device and manufacturing method thereof

A technology for display devices and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increased difficulty in manufacturing process and circuit drive, different response time of liquid crystal in the transmission area, and increased difficulty of manufacturing process, etc., to achieve the goal of manufacturing process And the effect of simple circuit driving, lower driving voltage, and consistent box thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

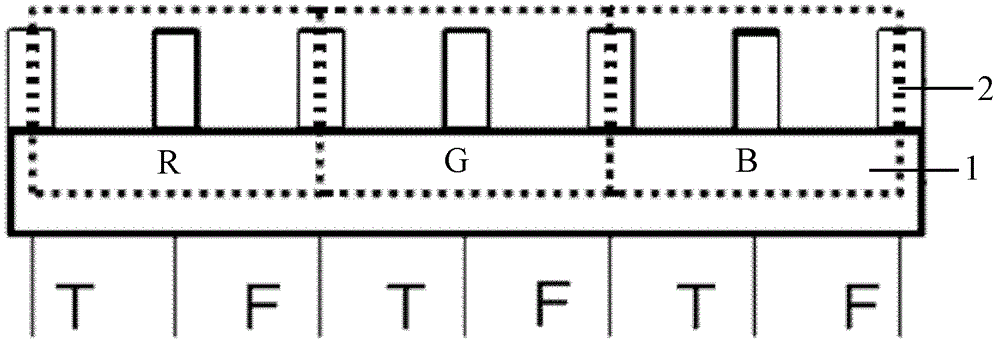

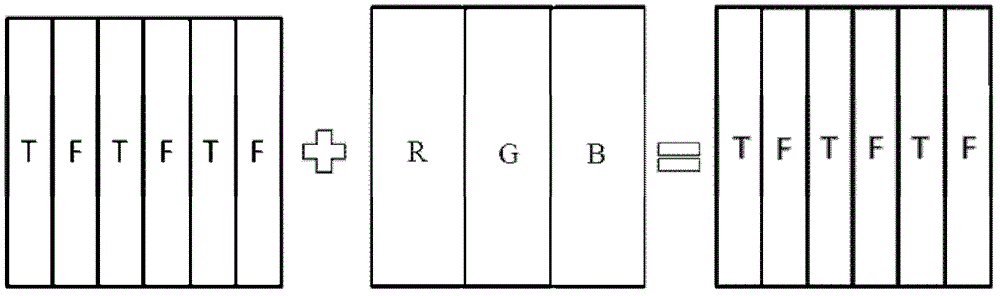

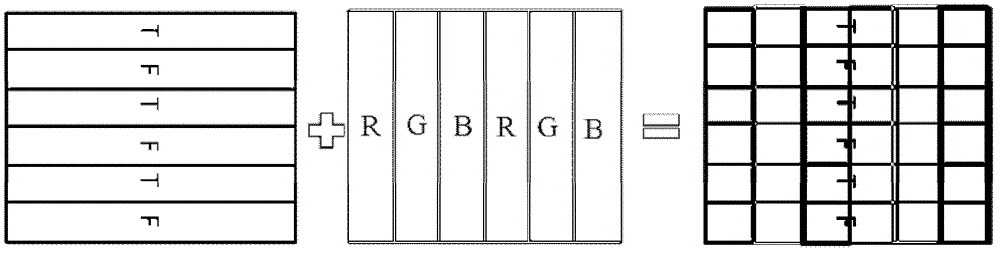

[0031] The display device provided in this embodiment includes a liquid crystal cell formed by pairing an array substrate and a color filter substrate, wherein wall-shaped electrodes arranged at intervals are formed on the array substrate, such as figure 1 As shown, the wall-shaped electrode 2 separates a row or a column of sub-pixels R or G or B on the color filter substrate, and divides each row or column of sub-pixels R or G or B into two rows or columns of sub-pixels, The areas where two rows or two columns of sub-sub-pixels are located respectively form a light transmission area T and a light reflection area F, thereby forming a plurality of adjacent grooves and walls corresponding to the transmission area T and reflection area F in the liquid crystal cell. The shaped electrode 2 is not only the separation of the transmissive area T and the reflective area F, but also serves as a signal electrode to provide a strong transverse electric field, and can also support the thick...

Embodiment 2

[0036] This embodiment provides a method for manufacturing the display device described in Embodiment 1, which includes the following processes:

[0037] First, wall-shaped electrodes are prepared on the array substrate.

[0038] Specifically, the photoresist material is coated on the array substrate, and photoetched through a mask to form wall-shaped electrodes arranged at intervals. The wall-shaped electrodes separate a row or a column of sub-pixels on the array substrate, and each row Or each column of sub-pixels is divided into two rows or two columns of sub-sub-pixels, and the regions where the two rows or two columns of sub-sub-pixels are located respectively form a light transmission area and a light reflection area arranged at intervals.

[0039] Secondly, screens are made in boxes.

[0040] Specifically, coating the frame sealant on the color filter substrate, curing the array substrate and the color filter substrate into boxes and cutting them into screens;

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com