Liquid crystal display panel and manufacturing method thereof

A liquid crystal display and panel technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of reducing the effective display area of the display area and contaminating the liquid crystal with sealing glue, so as to improve the display effect of the screen, improve the display quality and performance indicators , Reduce the effect of dark state brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

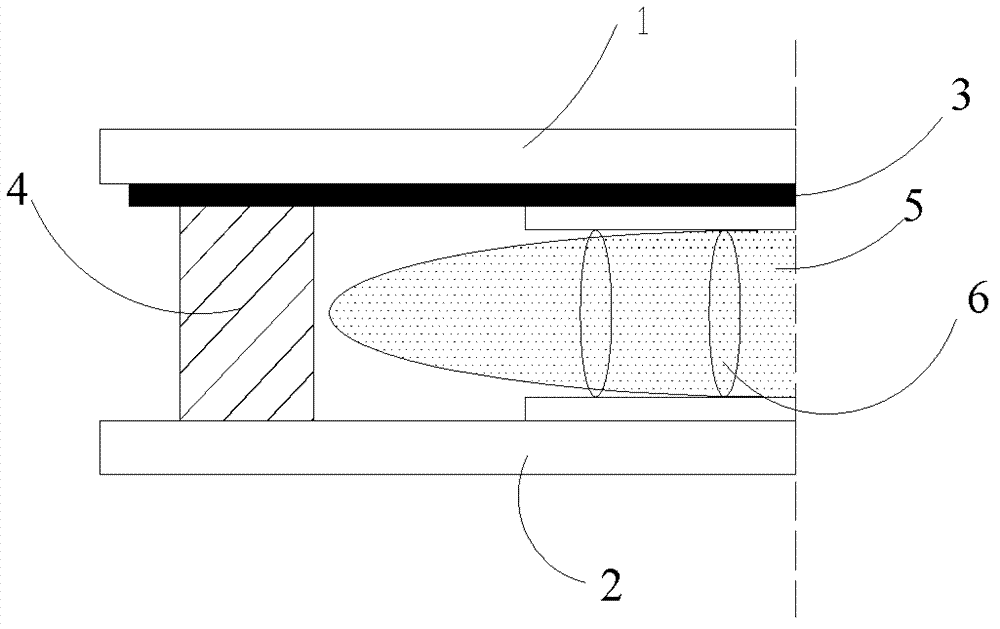

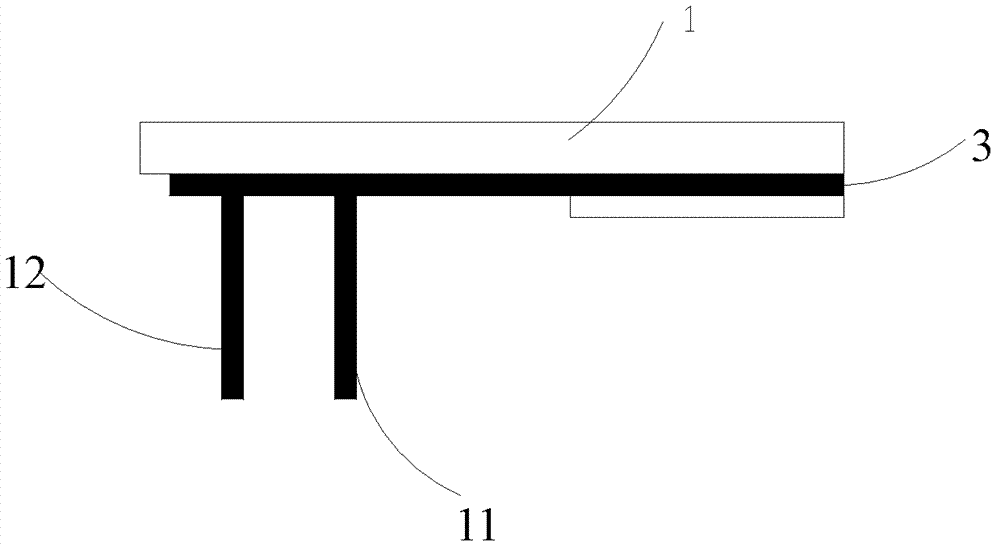

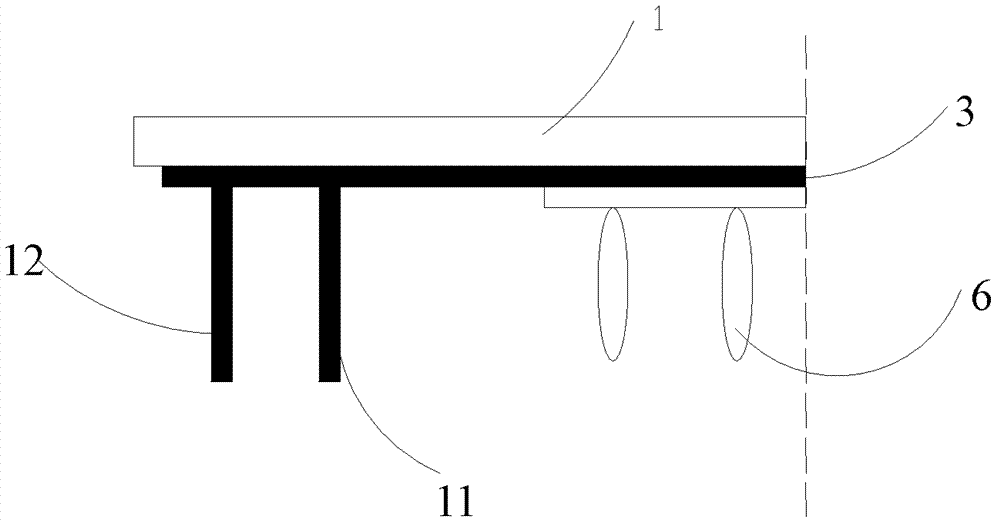

[0032] The liquid crystal display panel includes an upper substrate group and a lower substrate group, spacers are arranged between the two substrate groups, the surrounding frames of the two substrate groups are bonded by frame sealant, and liquid crystal is filled between the two substrate groups. Figure 5 Shows a schematic diagram of the peripheral structure of the liquid crystal display panel of this embodiment, where the upper substrate group is a color filter substrate 1, the lower substrate group is an array substrate 2, and the color filter substrate 1 is provided with a black matrix 3, and the color filter substrate 1 And the array substrate 2 is also provided with a liquid crystal alignment layer (not shown in the figure), the spacer 6 is arranged between the liquid crystal alignment layers, and an inner isolation layer 11 and an outer isolation layer 12 are arranged on the periphery of the two substrates, and the frame is sealed The glue 4 is coated between the inner...

Embodiment 2

[0038] The structure of the liquid crystal display panel of this embodiment is similar to the structure of the liquid crystal display panel described in Embodiment 1, with the difference that the isolation layer is only provided on the outside of the frame sealant to isolate the frame sealant from the external environment and avoid The external environment will cause corrosion, peeling or disconnection of the frame sealant. At the same time, it can also block the backlight from entering the peripheral area of the LCD panel, reduce the brightness in the dark state, and improve the contrast.

Embodiment 3

[0040] In this embodiment, the upper substrate group of the liquid crystal display panel is a color filter substrate with a black matrix and the lower substrate group is an array substrate as an example to introduce the manufacturing process of the liquid crystal display panel. The difference between the manufacturing process of the liquid crystal display panel of this embodiment and the manufacturing process of the liquid crystal display panel in the prior art is that before the frame sealant is applied between the color film substrate and the array substrate constituting the liquid crystal display panel, An inner isolation layer and an outer isolation layer are prepared on a substrate, so that the inner isolation layer and the outer isolation layer are in contact with the color filter substrate and the array substrate, and the sealant is coated between the inner isolation layer and the outer isolation layer.

[0041] The specific manufacturing process of the liquid crystal displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com