Process for the production of chlorine dioxide

A chlorine dioxide and alkali metal chlorate technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve problems such as complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In this patent application, the term "pump" refers to the explosive decomposition of chlorine dioxide into oxygen and chlorine during chlorine dioxide production. This phenomenon can be caused by impurities in the reaction mixture or by excessively high local temperatures ("hot spots").

[0023] The term "reaction mixture" refers to a mixture comprising an alkali metal chlorate, water, sulfuric acid and a reducing agent. Typically, the reaction mixture also contains chlorine dioxide and an alkali metal salt. Chlorine dioxide and alkali metal salts produced as by-products are removed from the reaction mixture. At a minimum, an aqueous alkali metal chlorate solution, sulfuric acid and reducing agent are fed to the remaining reaction mixture. Thus, the composition of the reaction mixture varies in the different process steps.

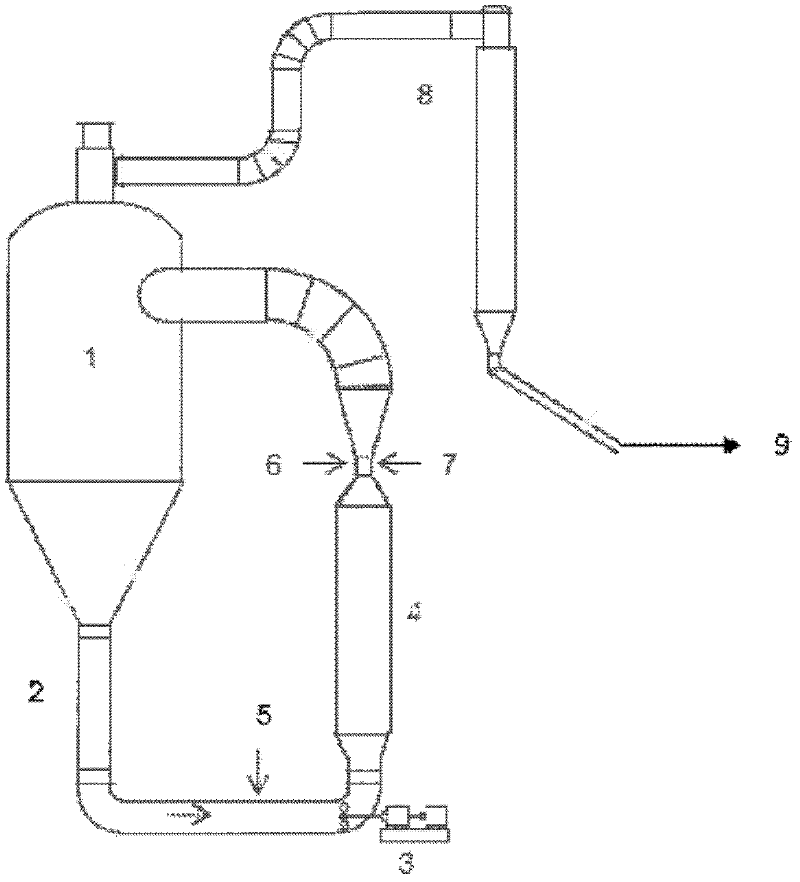

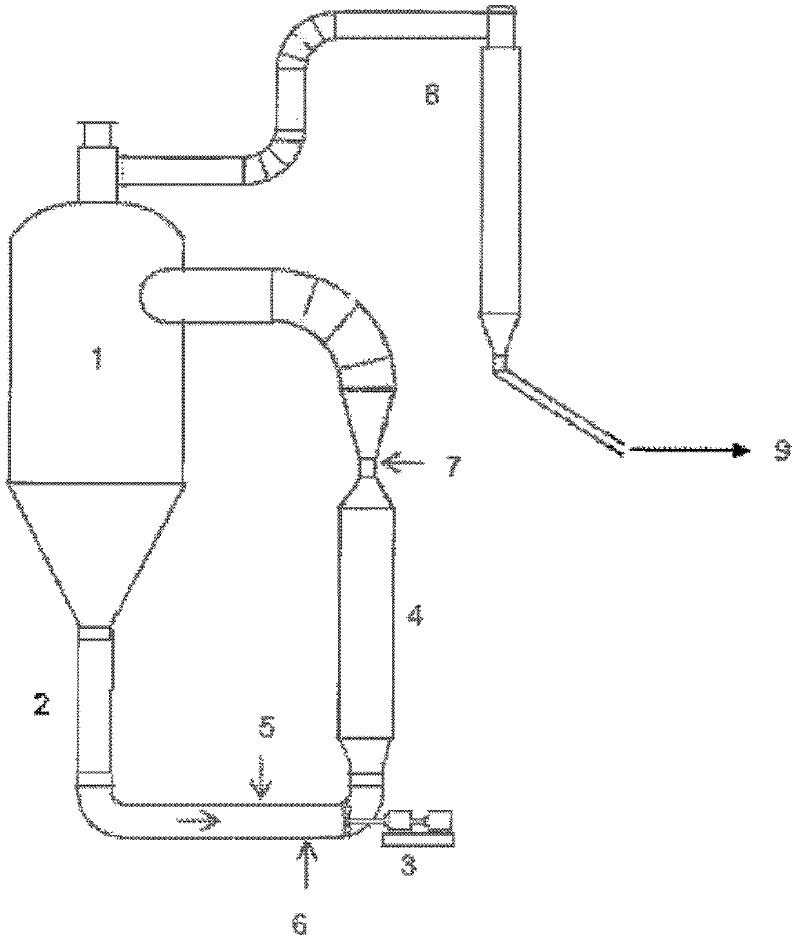

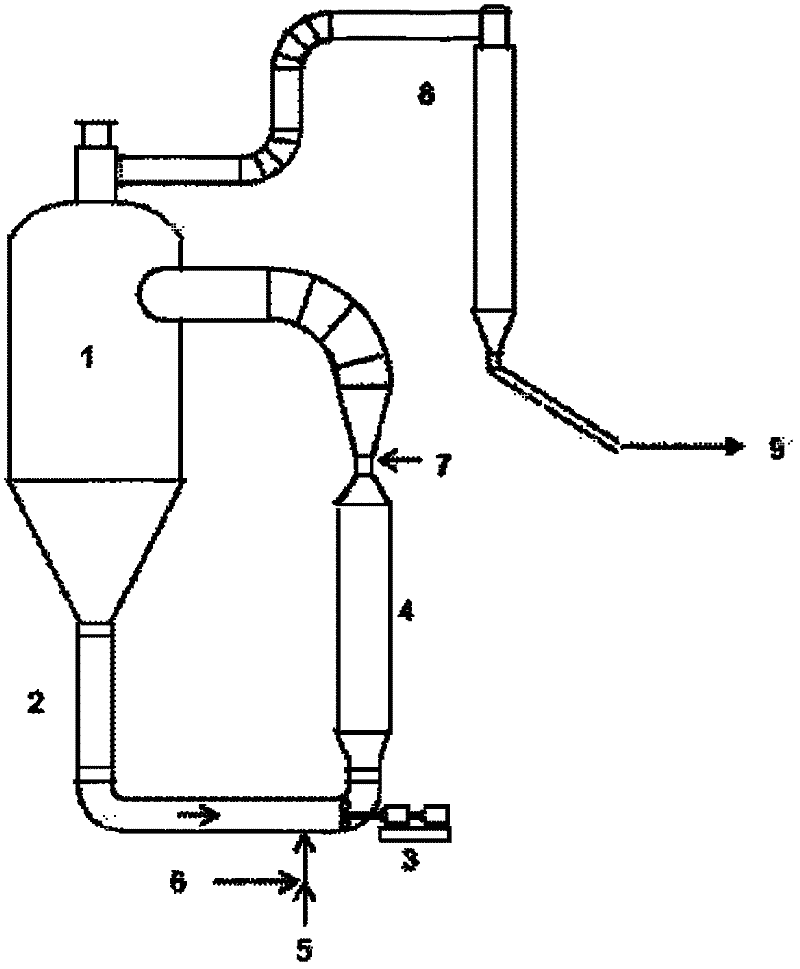

[0024] The invention relates to a process for the production of chlorine dioxide by means of a plant comprising a reaction vessel 1 operating un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com