Color-penetrated tile and making method thereof

A technology of bleeding and porcelain tiles, which is applied in the field of polished glazed tiles for interior decoration, can solve the problems of large polishing waste, occupying a large amount of land, and difficulty in recycling, etc., to reduce the amount of polishing, reduce the amount of production, and achieve rich colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

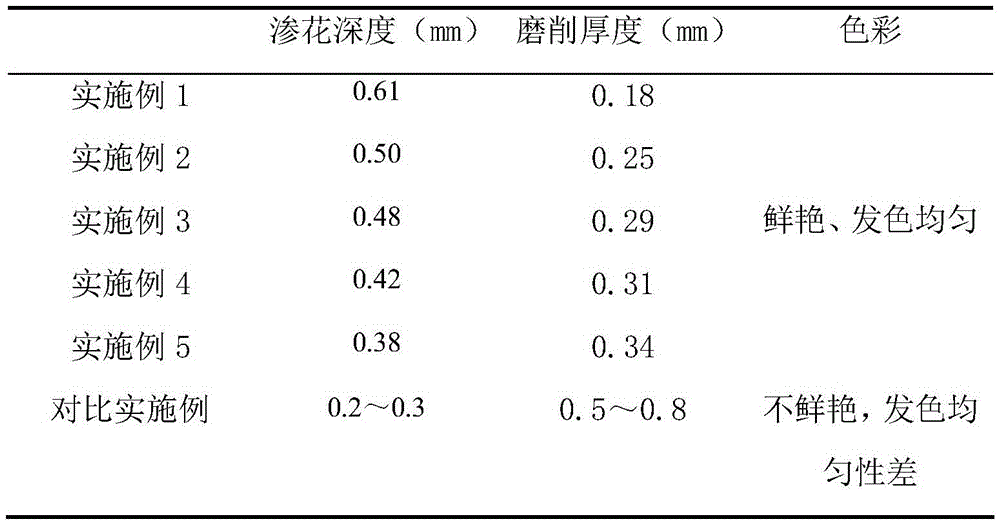

Examples

Embodiment 1

[0027] A kind of seepage tile, is prepared according to the following method:

[0028] (1) Porcelain tile raw material processing, according to the porcelain tile formula batching, ball milling, spray granulation to obtain the porcelain tile raw material granules;

[0029] (2) the preparation of water-soluble oozing flower ink, the water-soluble metal salt solution that one or more mixtures in Fe, Cr, Co, Cu, Au, Ag metal cations are included in the described ink,, described The ion mass concentration of the water-soluble metal salt solution is 5-15%;

[0030] (3) the preparation of surface glaze, described surface glaze is made up of following material by mass fraction: SiO 2 for 68 parts, Al 2 o 3 is 17 parts, MgO+CaO is 1 part, K 2 O+Na 2 O is 7 parts, ZnO is 2 parts, TiO 2 is 3 parts, BaO is 4 parts, B 2 o 3 0.5 parts, the rest are impurities, the fineness of the surface glaze is controlled at a standard sieve of 325 mesh, 2.0 parts are left after sieving, and the ...

Embodiment 2

[0040] A kind of seepage tile, is prepared according to the following method:

[0041] (1) Porcelain tile raw material processing, according to the porcelain tile formula batching, ball milling, spray granulation to obtain the porcelain tile raw material granules;

[0042] (2) the preparation of water-soluble bleeding ink, the water-soluble metal salt solution that one or more mixtures in Fe, Cr, Co, Cu, Au and / or Ag metal cations are included in the described ink, so The ion mass concentration of the water-soluble metal salt solution is 5-15%;

[0043] (3) the preparation of surface glaze, described surface glaze is made up of following material by mass fraction: SiO 2 for 59 parts, Al 2 o 3 is 15 parts, MgO+CaO is 1 part, K 2 O+Na 2 O is 10 parts, ZnO is 6 parts, TiO 2 is 2 parts, BaO is 5 parts, B 2 o 3 0.5 parts, and the rest are impurities. The fineness of the top glaze is controlled at a standard sieve of 325 mesh, with 1.5 to 2.5 parts remaining after sieving, t...

Embodiment 3

[0053] A kind of seepage tile, is prepared according to the following method:

[0054] (1) Porcelain tile raw material processing, according to the porcelain tile formula batching, ball milling, spray granulation to obtain the porcelain tile raw material granules;

[0055] (2) the preparation of water-soluble bleeding ink, the water-soluble metal salt solution that one or more mixtures in Fe, Cr, Co, Cu, Au and / or Ag metal cations are included in the described ink, so The ion mass concentration of the water-soluble metal salt solution is 5-15%;

[0056] (3) the preparation of surface glaze, described surface glaze is made up of following material by mass fraction: SiO 2 for 65 parts, Al 2 o 3 is 20 parts, MgO+CaO is 0.5 parts, K 2 O+Na 2 O is 3 parts, ZnO is 8 parts, TiO2 is 5 parts, BaO is 1 part, B 2 o 3 The fineness of the surface glaze is controlled at a standard sieve of 325 mesh, and the remaining 2.5 parts are sieved, the specific gravity is 1.85g / cm3, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com