Manufacturing machine of multi-width type full-automatic plastic drainage plate

A plastic drainage board, fully automatic technology, applied in the direction of thin material processing, lamination device, winding strip, etc., can solve the problems of high energy consumption, high cost, low efficiency, etc., and achieve low labor intensity and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

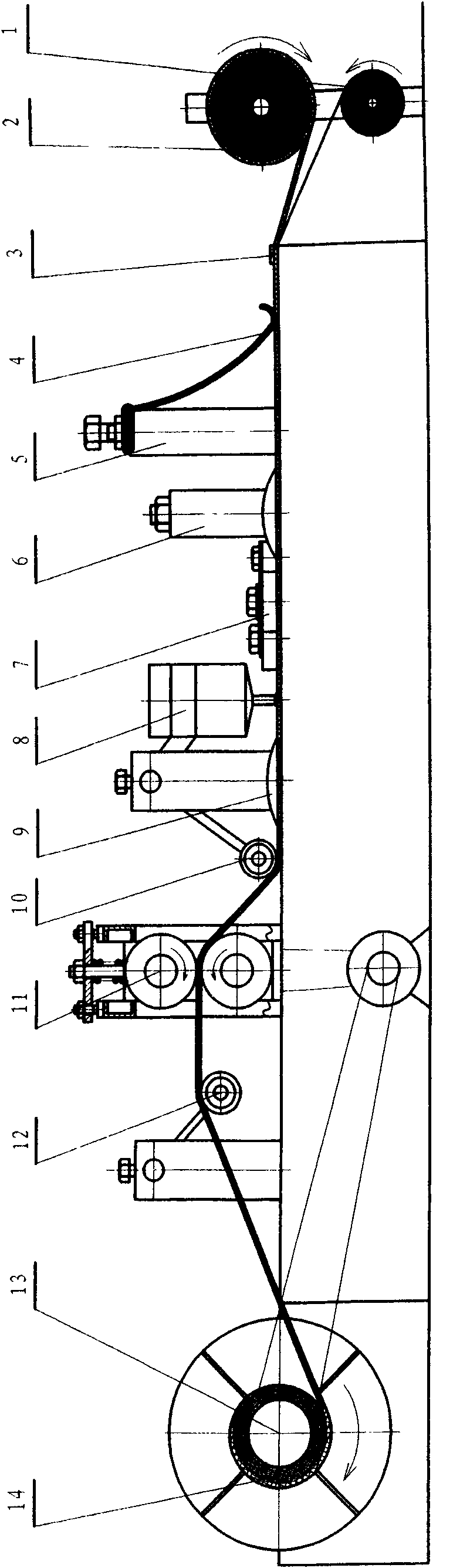

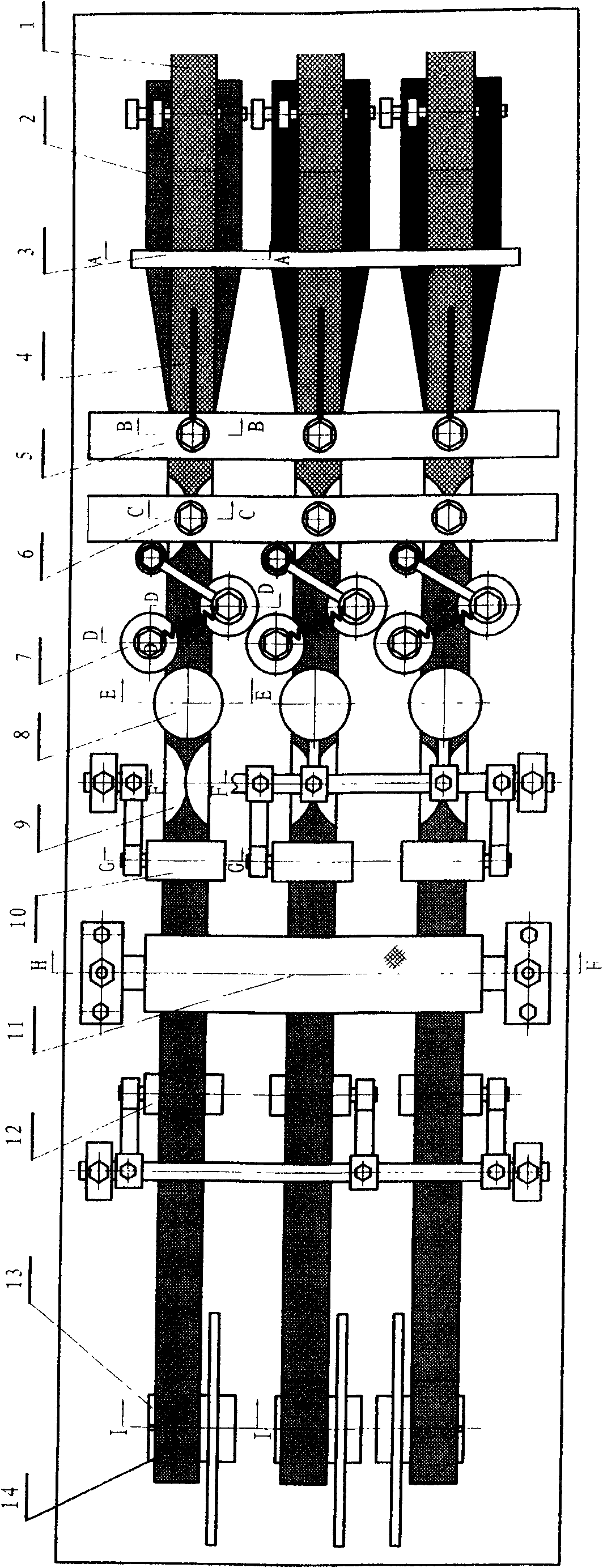

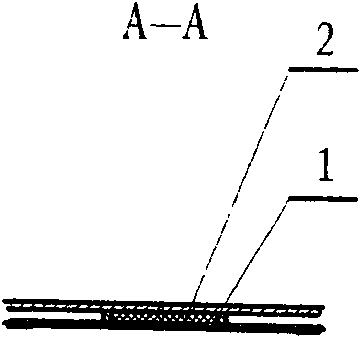

[0018] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 It is a schematic structural diagram of the main view of the present invention; figure 2 It is a schematic diagram of the top view structure of the present invention; figure 1 with figure 2 Middle: Interaction sequence of limiting plate 3, bead 4, primary coating device 5, secondary coating device 6, edge flattening device 7, gluing device 8, pasting device 9, and flattening device 10, in sequence A plurality of non-woven fabrics 1 are wrapped and fixed on the outer surfaces of a plurality of plastic core boards 2; and then a plurality of drainage boards 14 are synchronously wound into rolls by a traction device 11, idler rollers 12, and a winding device 13. image 3 Among them, the limiting plate 3 is made of iron plate welding. The size of the entrance depends on the size of the non-woven fabric 1 and the plastic core board 2. Generally, the non-woven fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com