Design of wheel leg type moving foot of multi-joint chain link type robot

A multi-joint, robot technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of strong anti-disturbance ability, high bearing capacity, wide reachable area of the foot end, etc., to achieve the effect of increasing torque and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

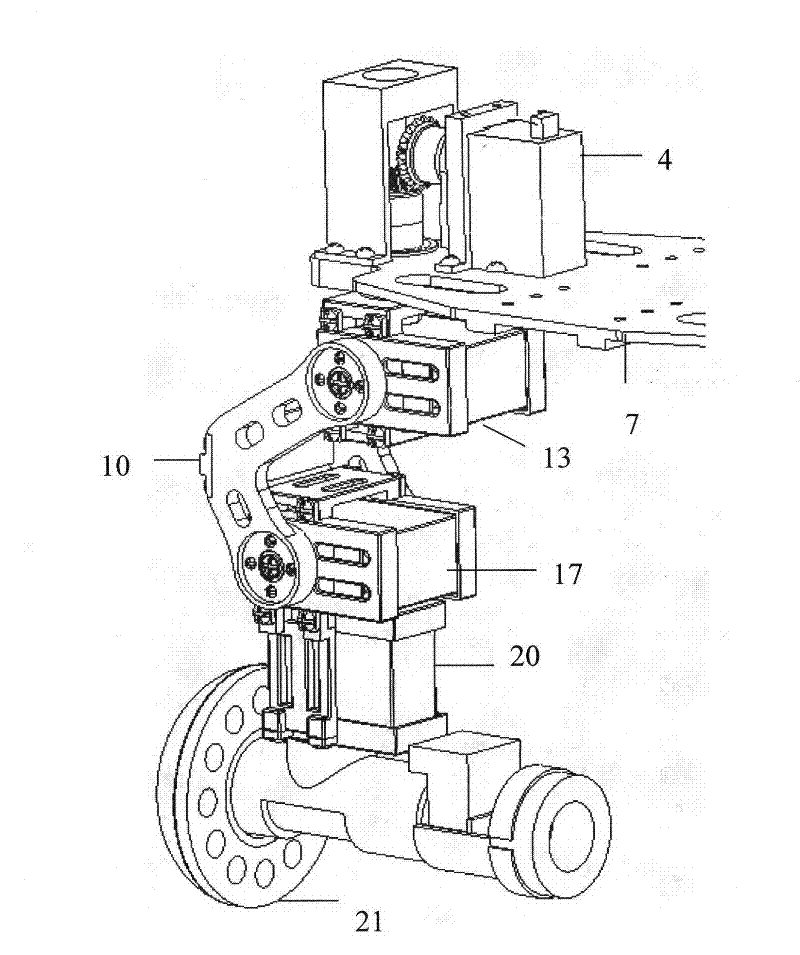

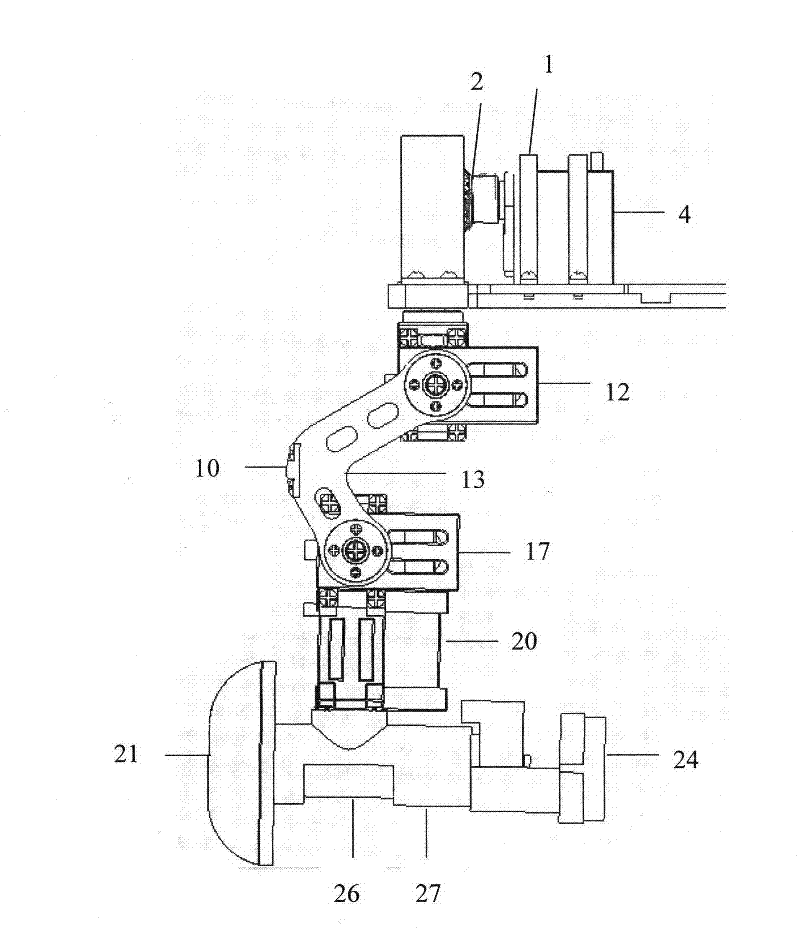

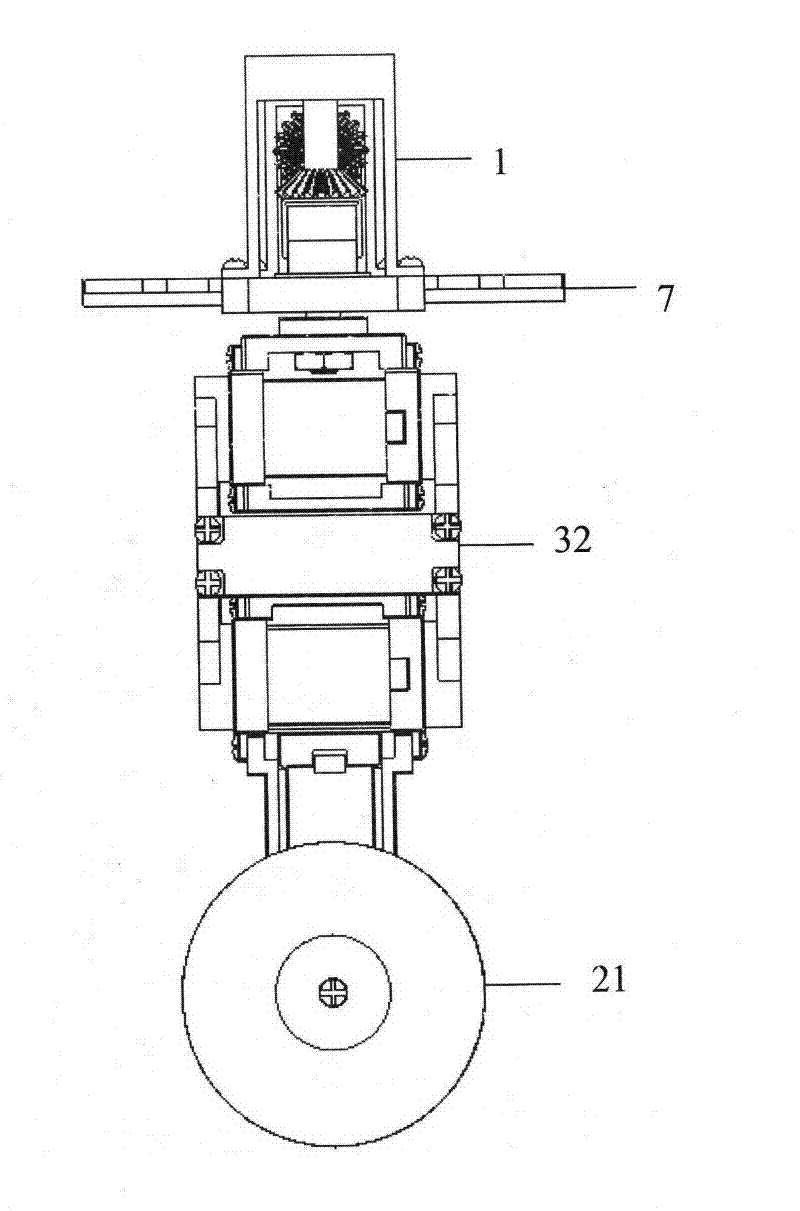

[0021] Such as figure 1 As shown, it is a schematic diagram of the single foot design of the wheel-legged sports foot of the multi-joint chain-link robot, including the No. 1 steering gear on the upper part of the connecting plate, the No. 2, No. 3, and No. motor. The surrounding structure of the steering gear includes: the bracket one (1) of the No. 1 steering gear (4) fixed by screws, the bevel gear (2), the bearing (3), the No. 1 shaft (6) and the bracket for connecting with the lower structure. The connection plate (7), the combination of the above mechanisms realizes the conversion of the horizontal rotation motion of the No. 1 steering gear into a vertical rotation motion. The No. 2 steering gear (13) is fixedly connected with four steering gear support frames by screws to realize the vertical rotation of the crank arm joint. No. 3 steering gear (17) is fixedly connected with four steering gear support frames by screws to realize the vertical rotation of the crank arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com