Novel alcohol-removing equipment for production of polyester polyol

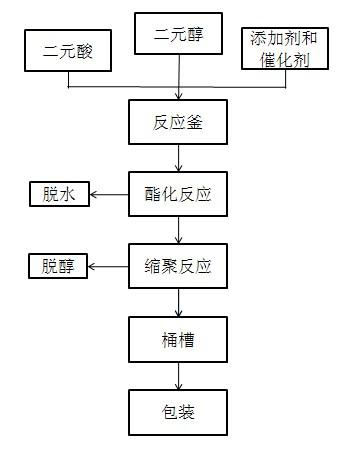

A polyester polyol and equipment technology, which is applied in the field of dealcoholization equipment for the production of new polyester polyol resins, can solve problems such as poor reactivity, and achieve the effects of preventing uneven molecular weight distribution, increasing stability, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

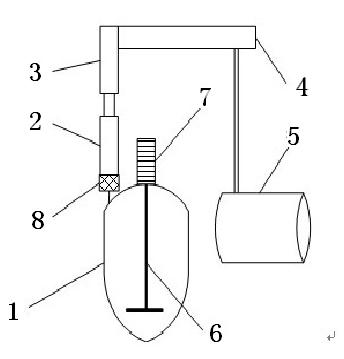

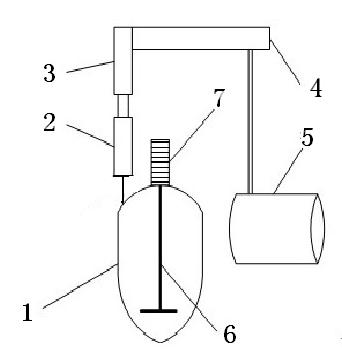

[0023] Such as figure 1 As shown, the novel polyester polyol resin production dealcoholization equipment of the present invention, this equipment comprises reactor 1, dealcoholization equipment 2 and condensation system, is provided with prevent small molecule And the butterfly valve 8 for by-product reflux. An outlet is arranged on the oblique upper side of the reaction kettle. The outlet of the reaction kettle is sealed and connected to the inlet of the dealcoholization equipment through the butterfly valve 8, and the outlet of the dealcoholization equipment is connected to the inlet of the condensation system. The reaction kettle is provided with a stirring mechanism, and the stirring mechanism includes a stirrer 7 arranged directly above the reaction kettle and a stirring shaft 6 fixedly connected with the stirrer and extending to the inside of the reaction kettle. The device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com