A high-temperature corrosion inhibitor for inhibiting corrosion of high-acid value crude oil and its application

A high-temperature corrosion inhibitor and high acid value technology, applied in the field of high-temperature corrosion inhibitors and corrosion inhibitors, can solve problems such as corrosion and achieve stable adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] ①Weigh 24g of phenol and 60g of xylene into another five-neck flask, stir and raise the temperature to 30°C, control the temperature at 30°C-60°C, and slowly add 14g of phosphorus pentasulfide in batches. After the feeding is completed, react at a constant temperature of 110°C for 3 hours, then raise the temperature to 150°C, and react at a constant temperature for 2 hours;

[0018] ② Mix the reaction product of step ① with 35 g of undecyl imidazoline, stir and heat up, and react at 60°C-70°C for 30 minutes;

[0019] ③Mix the reaction product of step ② with oleic acid imidazoline amide at a mass percentage ratio of 5:1 to obtain a corrosion inhibitor.

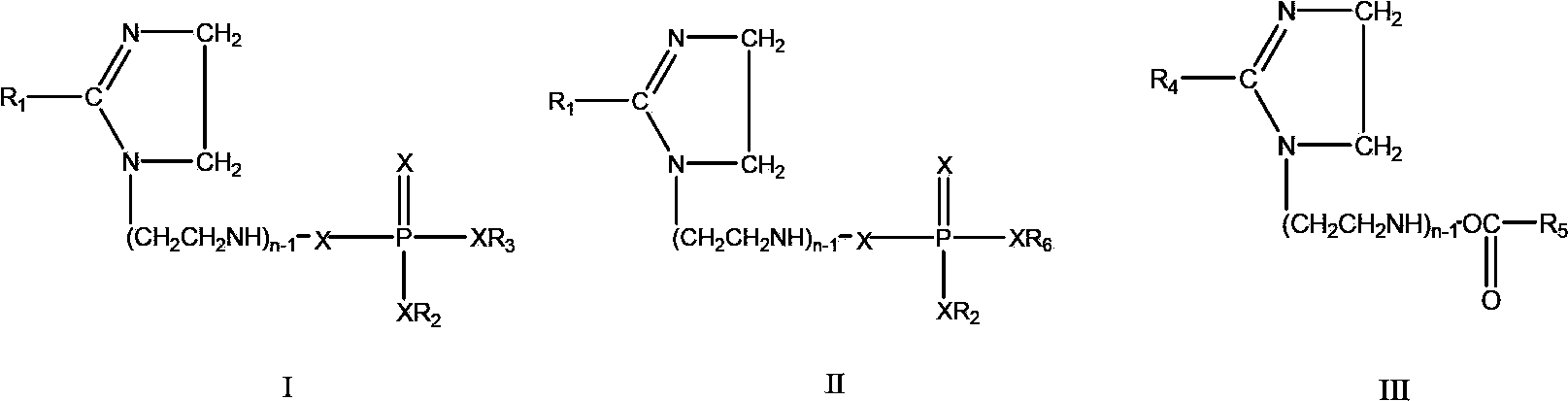

[0020] Among them, R 3 The same structure as R6, therefore, imidazoline aryl phosphate (I1) and (II1) are the same substance, the mass ratio of its total mass to imidazoline amide (III1) is 5:1, and the structural formula is:

[0021]

Embodiment 2

[0023] ① Weigh 12g phenol, 16g isooctyl alcohol and 70gC 9 Add heavy aromatics to another five-necked flask, stir and heat up to 30°C, control the temperature at 30°C-60°C, and slowly add phosphorus pentoxide 9g in batches. After the feeding is completed, react at a constant temperature of 60°C for 4 hours, then raise the temperature to 100°C, and react at a constant temperature for 2 hours;

[0024] ② Mix the reaction product of step ① with 50g of 9-heptadecenyl imidazoline, stir and heat up, and react at 60°C-70°C for 30 minutes;

[0025] ③Mix the reaction product of step ② with lauric acid imidazoline amide at a mass percentage ratio of 3:1 to obtain a corrosion inhibitor.

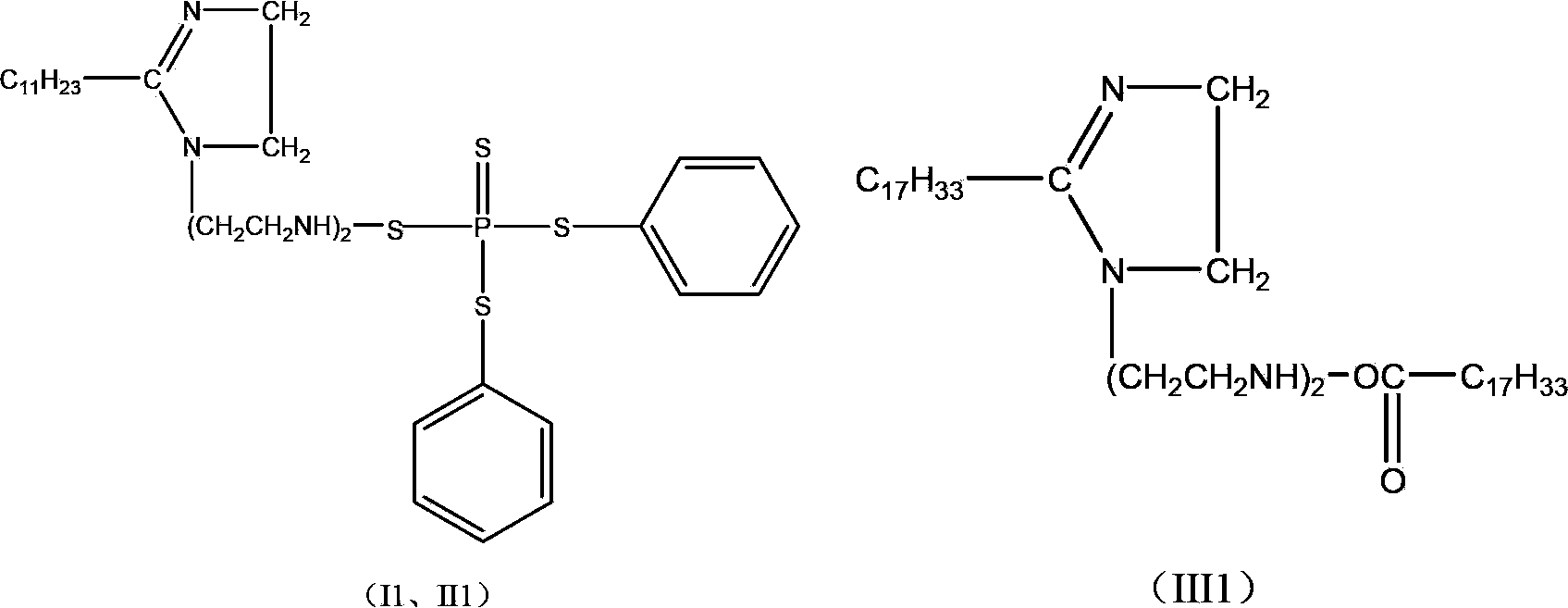

[0026] The mass ratio of the total mass of imidazoline aryl phosphate (I2) and (II2) to imidazoline amide (III2) is 3:1, and the structural formula is:

[0027]

Embodiment 3

[0029] ① Weigh 20g phenol, 5g benzyl alcohol and 70gC 10 Add the heavy aromatics to another five-necked flask, stir and raise the temperature to 40°C, control the temperature at 40°C-110°C, and slowly add phosphorus pentasulfide 14g in batches. After the feeding is completed, react at a constant temperature of 110°C for 3 hours, then raise the temperature to 150°C, and react at a constant temperature for 2 hours;

[0030] ②Mix the reaction product of step ① with 50g of 9,12-heptadecadienyl imidazoline, stir and heat up, and react at 60°C-70°C for 30 minutes;

[0031] ③Mix the reaction product of step ② with naphthenic acid imidazoline amide at a ratio of 1:3 by weight to obtain a corrosion inhibitor.

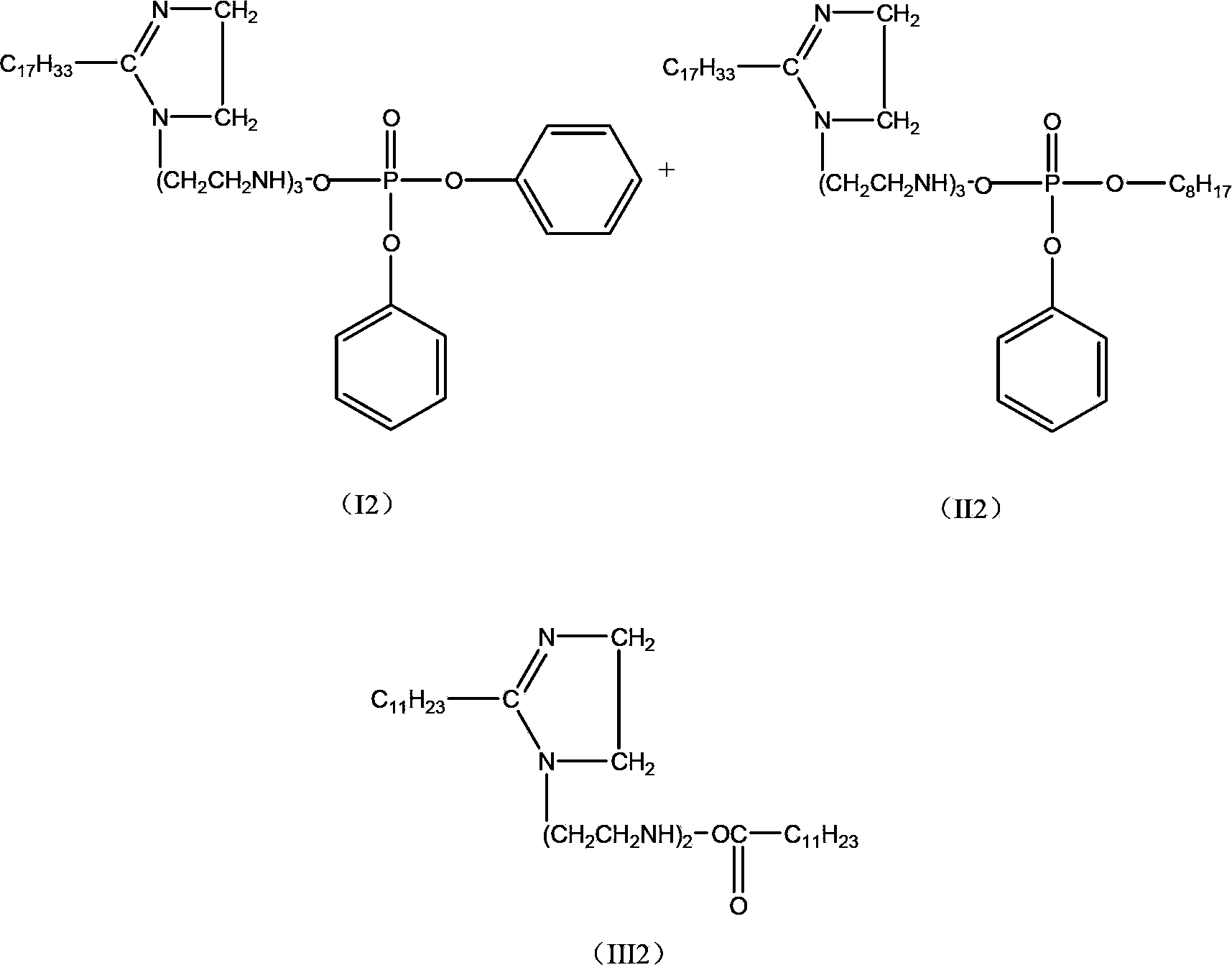

[0032] The mass ratio of the total mass of imidazoline aryl phosphate (I3) and (II3) to imidazoline amide (III3) is 1:3, and the structural formula is:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com