Bicycle power generation device with automatic clutch

An automatic clutch and generator technology, applied in the direction of automatic clutch, clutch, circuit device, etc., can solve the problems of worn tires, troublesome installation and maintenance of generator hubs, and laborious riding, and achieve stable output current and simple installation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

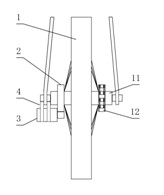

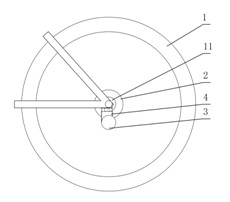

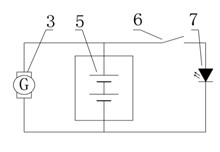

[0016] like figure 1 , figure 2 As shown, it includes a DC generator 3, a centrifugal clutch 2, the centrifugal clutch 2 is installed on the rear wheel axle 11 of the bicycle through a one-way bearing, the DC generator 3 is installed on the rear fork of the bicycle through a bracket 4, and the DC generator 3 and the centrifugal clutch 2 pass through Mechanical transmission connection. When the bicycle is riding, the sprocket 12 drives the rear wheel 1 and the rear axle 11 to rotate. At this time, the DC generator 3 does not work. When the rear axle 11 reaches a certain speed, the centrifugal clutch 2 is combined and drives the DC generator to generate electricity through mechanical transmission. Since the centrifugal clutch 2 is combined to drive the DC generator 3 to work when the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com