Improved transparent water-based conductive high polymer mixer

A technology of conductive polymer and mixing equipment, applied in the field of improved transparent water-based conductive polymer mixing equipment, can solve problems such as affecting the continuity and efficiency of material distribution, single rotary motion, unclean discharge, etc. Forced slip, low operating noise, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

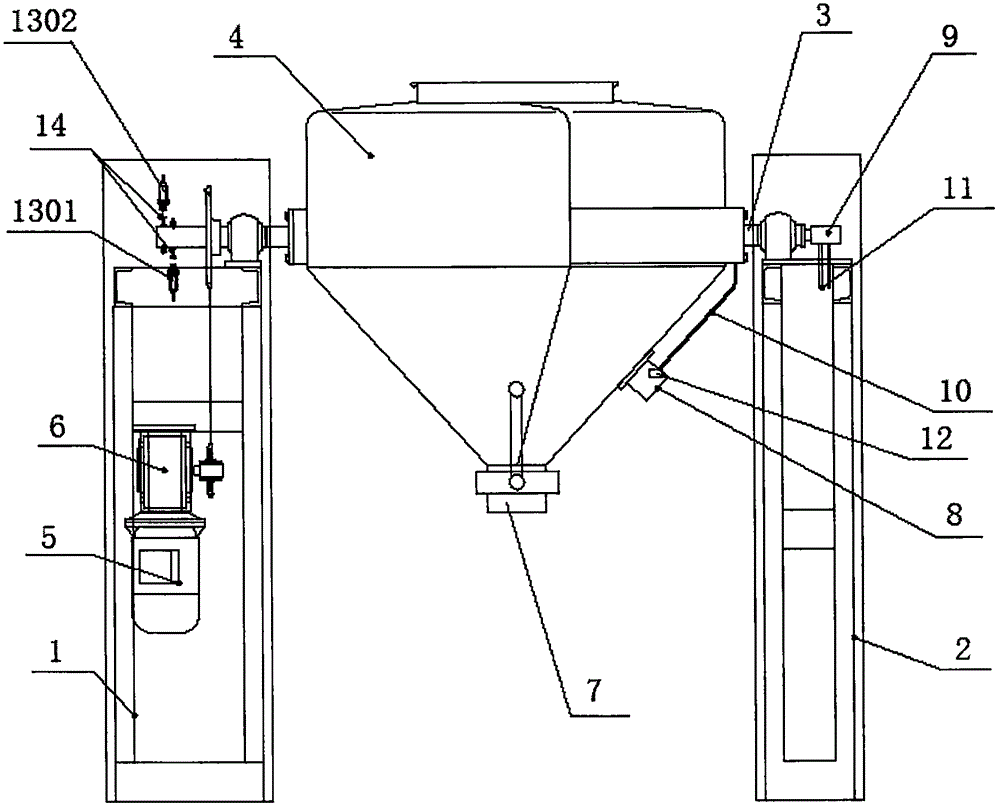

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0020] like figure 1 As shown, an improved transparent water-based conductive polymer mixing device of the present invention includes a left frame 1 and a right frame 2, and a mixing shaft 3 is fixed between the left frame 1 and the right frame 2. Hopper 4; the left frame 1 is provided with a brake motor 5 and a speed reducer 6, the brake motor 5 is connected with the speed reducer 6, and the speed reducer 6 is placed on the brake motor 5 above; the lower part of the mixing hopper 4 is provided with a discharge valve 7; the outer wall of the mixing hopper 4 is provided with a pneumatic vibrator 8, and the right frame 2 is provided with a compressed air rotary joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com