Viscose fiber waste gas treatment control system

A waste gas treatment and control system technology, which is applied in the general control system, control/regulation system, program control, etc., can solve the problems of high operation risk, high device operation cost, and high cost, and achieve simple installation and maintenance operations and stable recovery The effect of high efficiency and recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

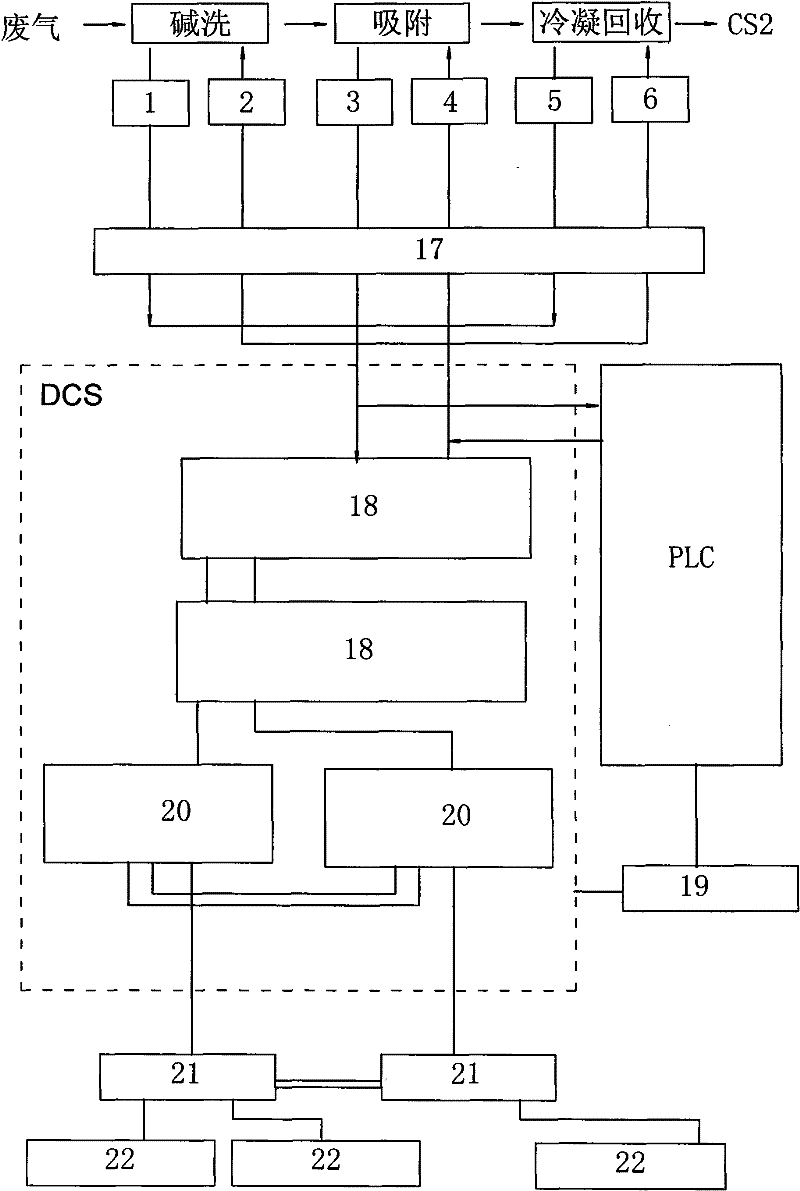

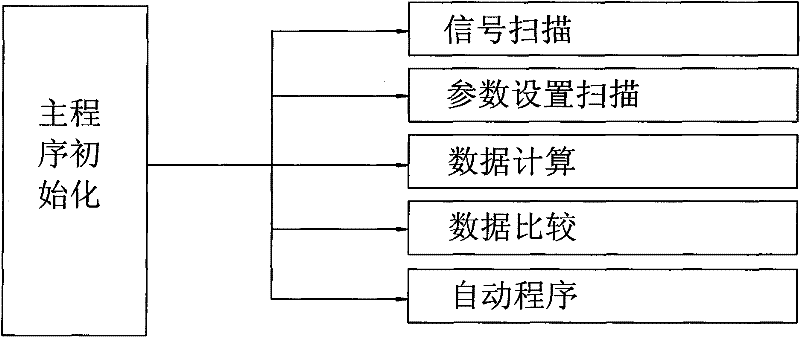

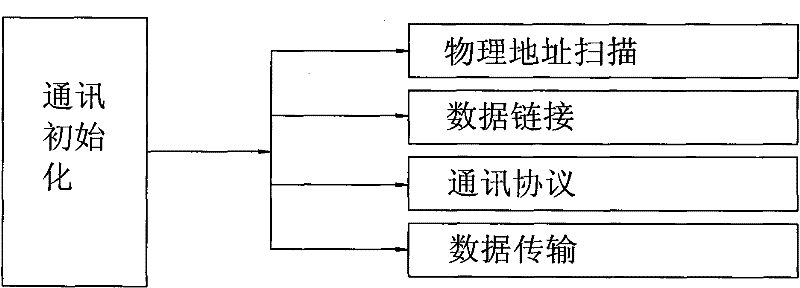

[0022] see Figure 1 to Figure 6, The invention relates to a viscose fiber waste gas treatment control system, which adopts the control idea of decentralized control, centralized operation, hierarchical management, flexible configuration and convenient configuration in design. The control device mainly includes two parts: the distributed control system DCS and the programmable controller PLC. The distributed control system DCS is the main part, and the programmable controller PLC is the backup. The distributed control system DCS is equipped with two sets of redundant control modules 20, two sets of redundant switches 21, two sets of input and output modules 18 and wired communication networks for connection, which are composed of power supply, CPU, and communication modules. Adopt optical fiber communication between 20, adopt optical fiber communication between two redundant switches 21, also can set up field operation station 22 (redundant operation station, engineer statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com