Automatic control system of multifunctional drying machine

An automatic control system and drying machine technology, applied in the direction of drying machine, drying gas arrangement, drying, etc., can solve the problems of the quality change of the goods to be dried, the inability to dry the goods accurately, and the impact on the quality of the goods, so as to achieve fast control speed and guarantee Normal and stable operation, avoiding the effect of program running away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

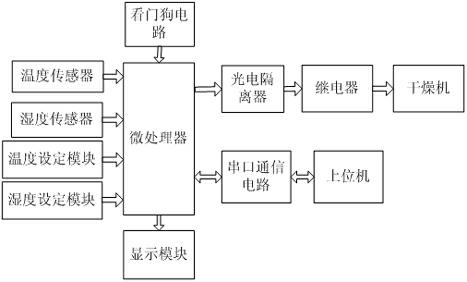

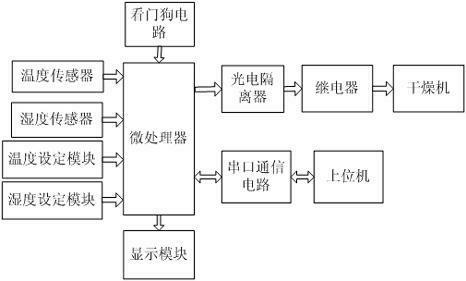

[0011] Such as figure 1 As shown, an automatic control system for a multifunctional dryer includes a microprocessor, a humidity sensor and a temperature sensor connected to the microprocessor, and is characterized in that it also includes a humidity setting module, a temperature setting module, a photoelectric isolation device, relay, dryer and host computer, the humidity setting module and temperature setting module are respectively connected to the microprocessor, the host computer is connected to the microprocessor through a serial port communication circuit, and the microprocessor is sequentially Connected through photoelectric isolator, relay and dryer.

[0012] The present invention collects the temperature and humidity information of the items to be dried through the temperature sensor and the humidity sensor, then inputs them into the microprocessor, compares ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com