Sound wave penetrating through moving unit body detecting method for structural concrete

A mobile unit and detection method technology, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of huge workload and long detection cycle, and achieve the effect of large control range, less workload and increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Site layout and observation

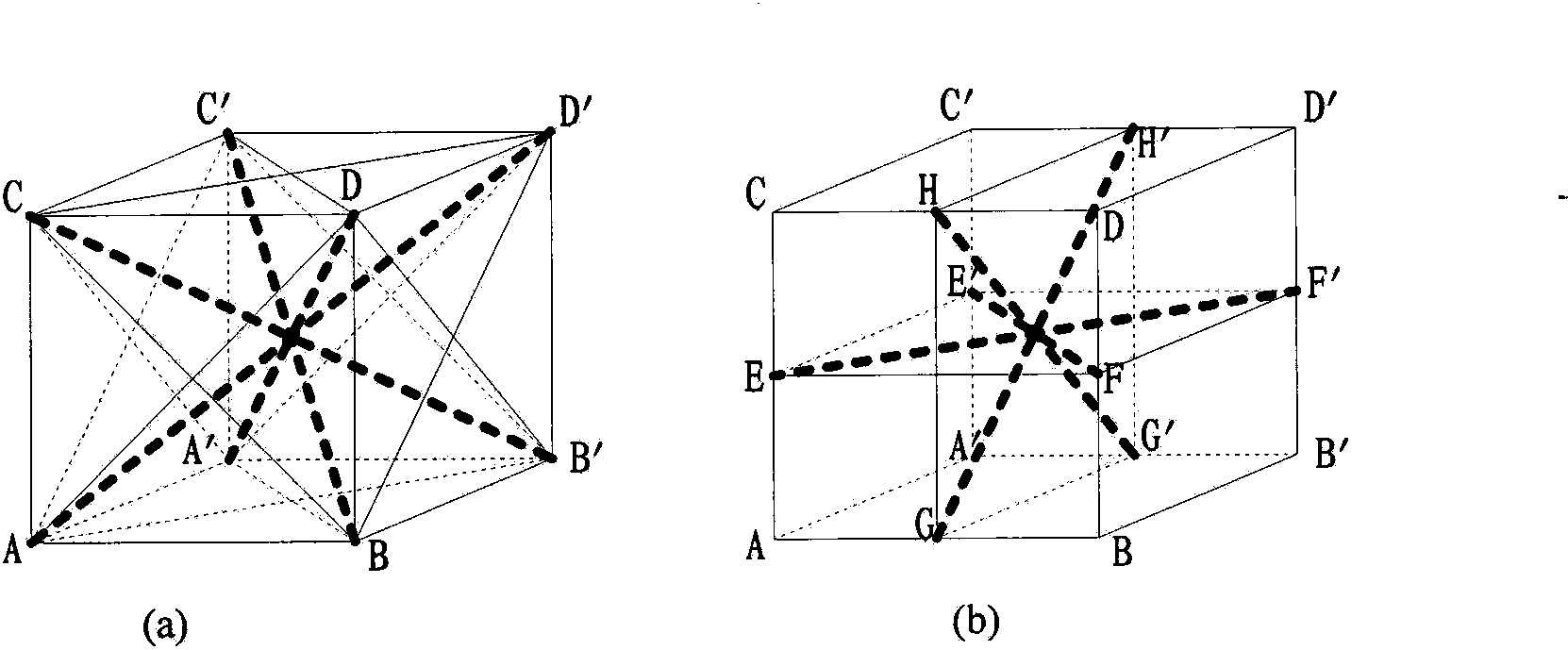

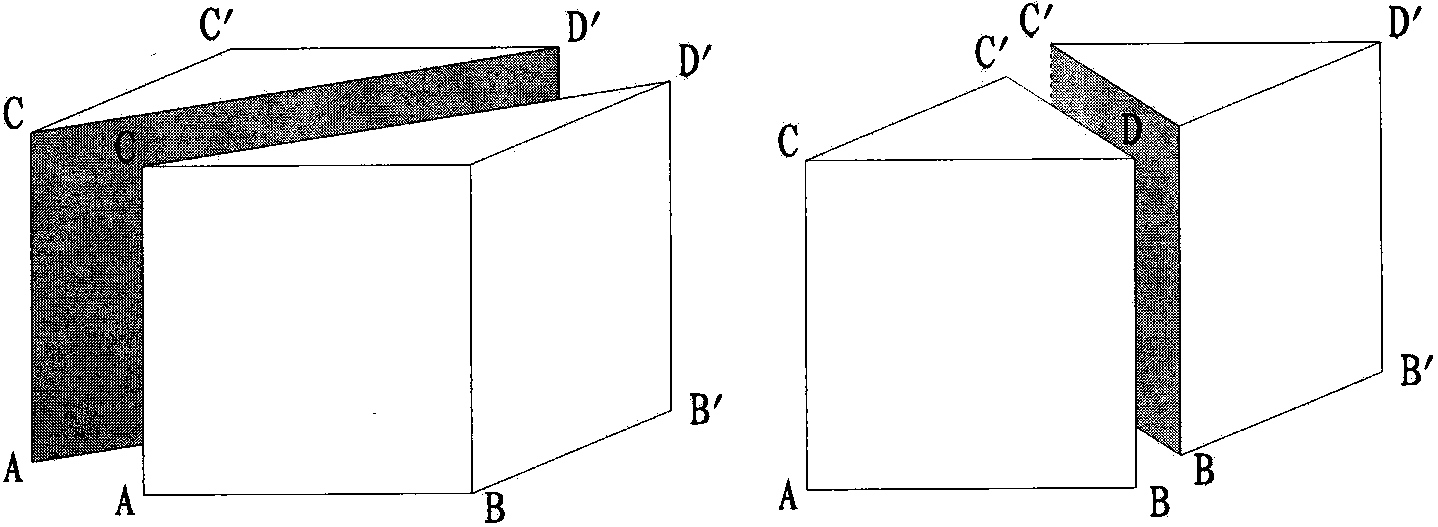

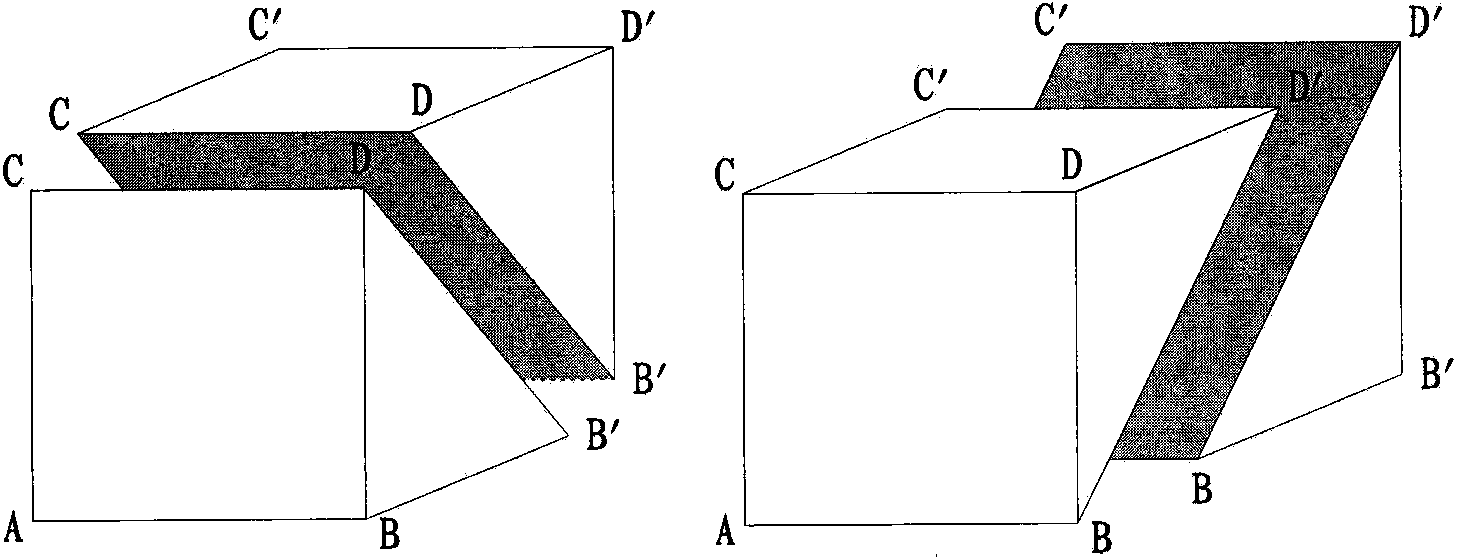

[0064] The concrete acoustic wave penetration mobile unit method for the first phase of the vertical ship lift rack in a hydropower project is tested. The test unit is arranged according to the aforementioned method. See Figure 5 , the thickness between the inner and outer surface of the concrete wall of the first phase of the vertical ship lift rack is 1.5m (the distance between point 1 and point 1'), and the distance between point 1 and point 3 is 1.2m, Penetrating Rays Stereogram Reference image 3 (a), adopt the "gradual movement" method in the longitudinal direction of the concrete wall of the first phase of the vertical ship lift rack, and the moving point distance is 0.1m, and a continuous vertical plane will be formed in the longitudinal direction, that is, the thick black line in the figure is The horizontal projection of the penetrating ray or each thick black line represents a vertical section, such as 1~3', 3~1' vertical secti...

Embodiment 2

[0072] The concrete acoustic wave penetration mobile unit method for the first phase of the vertical ship lift rack in a hydropower project is tested. The test unit is arranged according to the aforementioned method. See Figure 9 , the thickness between the inner and outer concrete surfaces of the first phase of the vertical ship lift rack is 1.5m (the distance between point 1 and point 1'), and the distance between point 1 and point 3 is 1.2m. The concrete wall of the first stage of the ship lift rack adopts the "gradual movement" method in the vertical direction, with a moving point distance of 0.1m, and the "building block movement" method in the horizontal direction to the right, with a moving step distance of 1.2m, forming a continuous control in the longitudinal direction. Vertical plane, that is, the black thick line in the figure is the horizontal projection of the penetrating ray or each black thick line represents a vertical plane, such as 1~3', 3~1'3~3', 3~5' vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com