Oil-water separation chamber with multi-circuitous channels

An oil-water separation tank and circuitous channel technology, which is applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of low separation efficiency, poor separation effect, no energy saving and emission reduction of the separation tank, and improve production efficiency. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

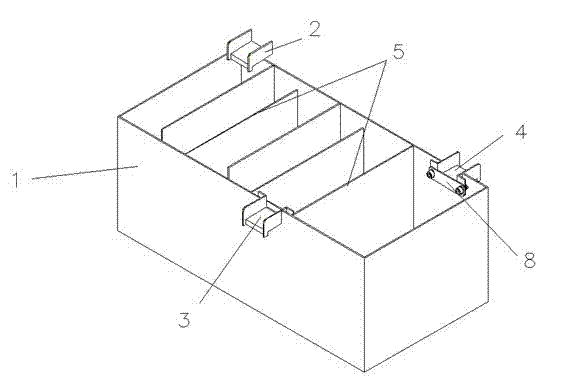

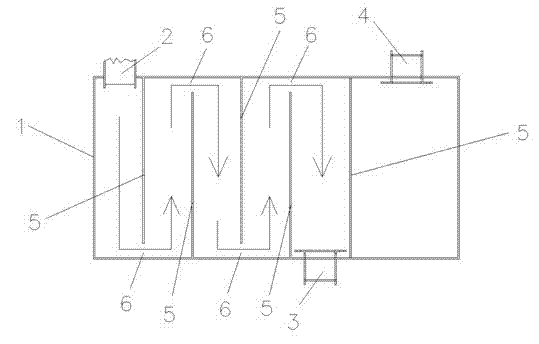

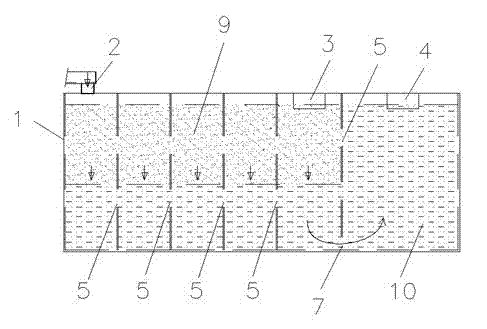

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an oil-water separation tank with multiple detours, including a separation tank 1, the separation tank is a cubic tank body, and the separation tank is respectively provided with a mixed liquid inlet 2, a lubricating oil overflow port 3 and The chip liquid overflow port 4; the separation tank is provided with multiple partitions 5, the partitions divide the separation tank into a plurality of small cavities, and the front several partitions are provided with gaps 6 laterally, so that the separation tank is formed A multiple circuitous channel structure, the last partition is a lateral fully enclosed partition, a gap 7 is opened at the bottom of the partition, the chip liquid overflow port is set on the top of the last small cavity, and the lubricating oil overflow port is set on the chip The top of the front chamber of the liquid overflow.

[0020] The lubricating oil overflow port and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com