Hydraulic pump, in particular a fuel pump

A technology of hydraulic pumps and fuel pumps, which is applied in the field of hydraulic pumps and can solve problems such as wear, energy consumption, and high energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

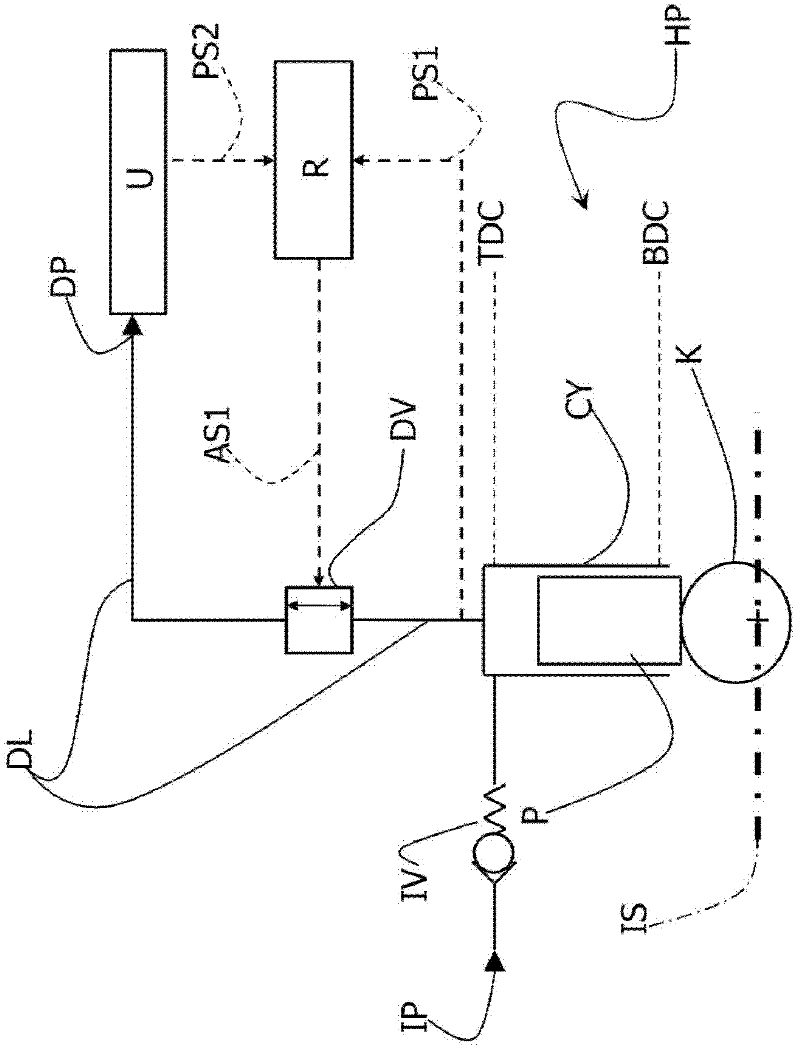

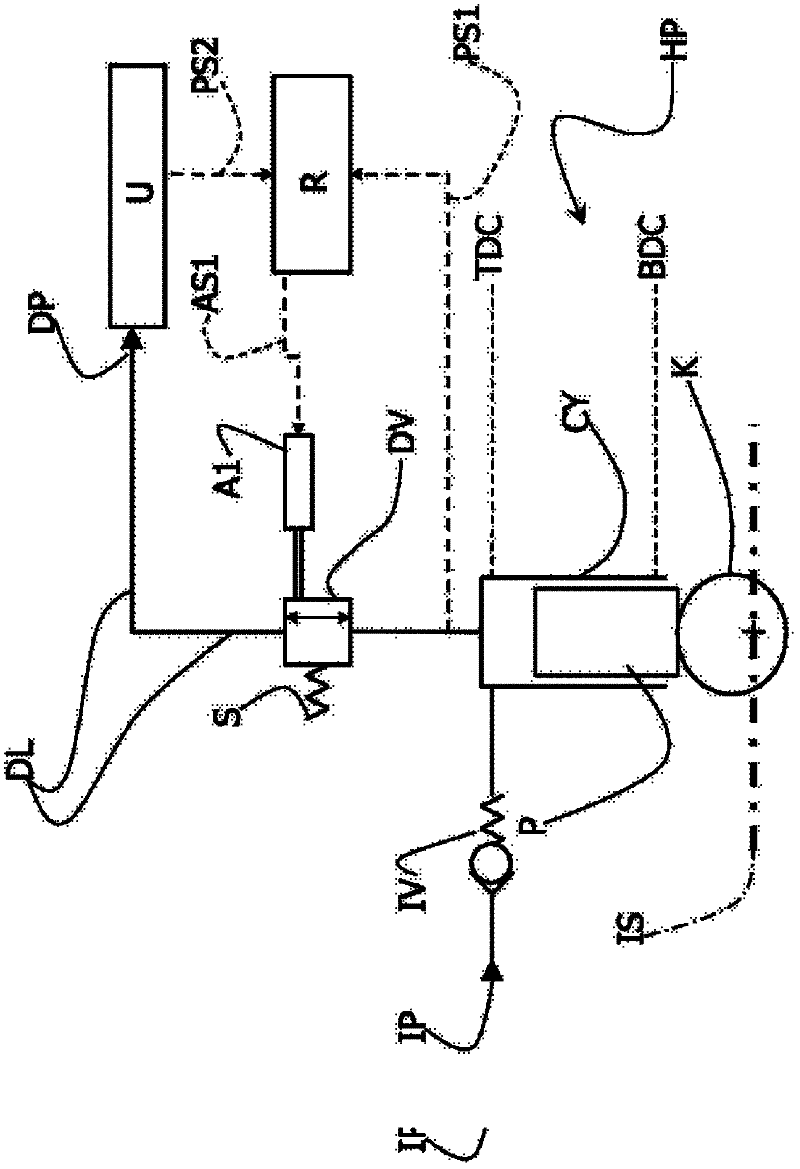

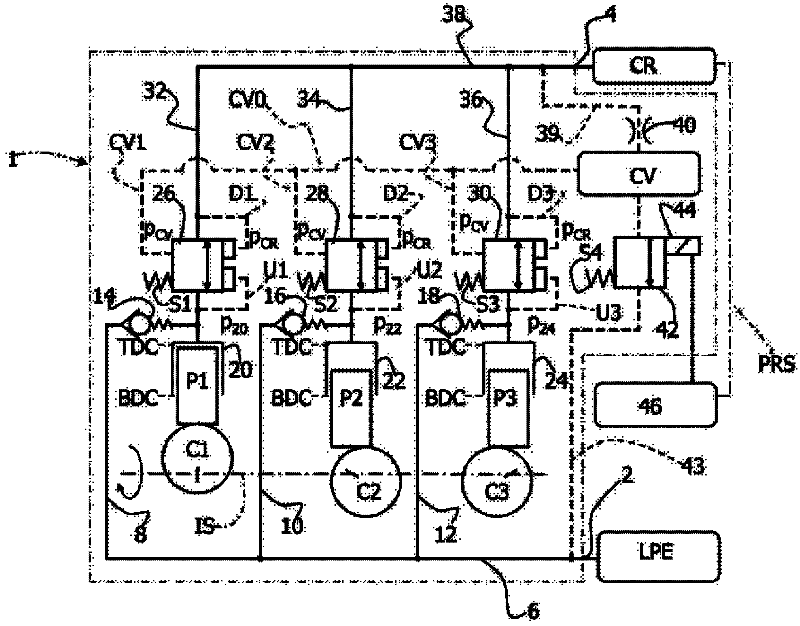

[0018] exist figure 1 , the reference sign HP designates hydraulic pumps according to different embodiments of the present invention. The pump HP comprises an inlet IP, an outlet DP and at least one cylinder CY in which a piston P is reciprocated by a mechanism K, such as a cam or crank mechanism, which in turn is actuated by an input shaft IS. Each piston P reciprocates between top dead center TDC and bottom dead center BDC.

[0019] As is known, the inlet IP is arranged in communication with the inlet port environment (not shown) and is in fluid communication with the cylinder CY through the inlet valve IV.

[0020] Furthermore, the cylinder CY is in fluid communication with the outlet DP via a delivery line DL on which a delivery valve DV controllable by means of an adjustment assembly R is arranged.

[0021] Delivery valve DV is movable between an open position arranged to allow fluid flow between cylinder CY and outlet DP and a closed position in which said fluid flow i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap