Corrosion-assistance liquid pump for etching machine of circuit board

A corrosion-resistant, etching machine technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of production planning and product quality adverse effects, stainless steel shaft corrosion damage, liquid leakage, etc., to reduce maintenance labor intensity and equipment maintenance Cost expenditure, improvement of corrosion resistance, and the effect of solving frequent failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

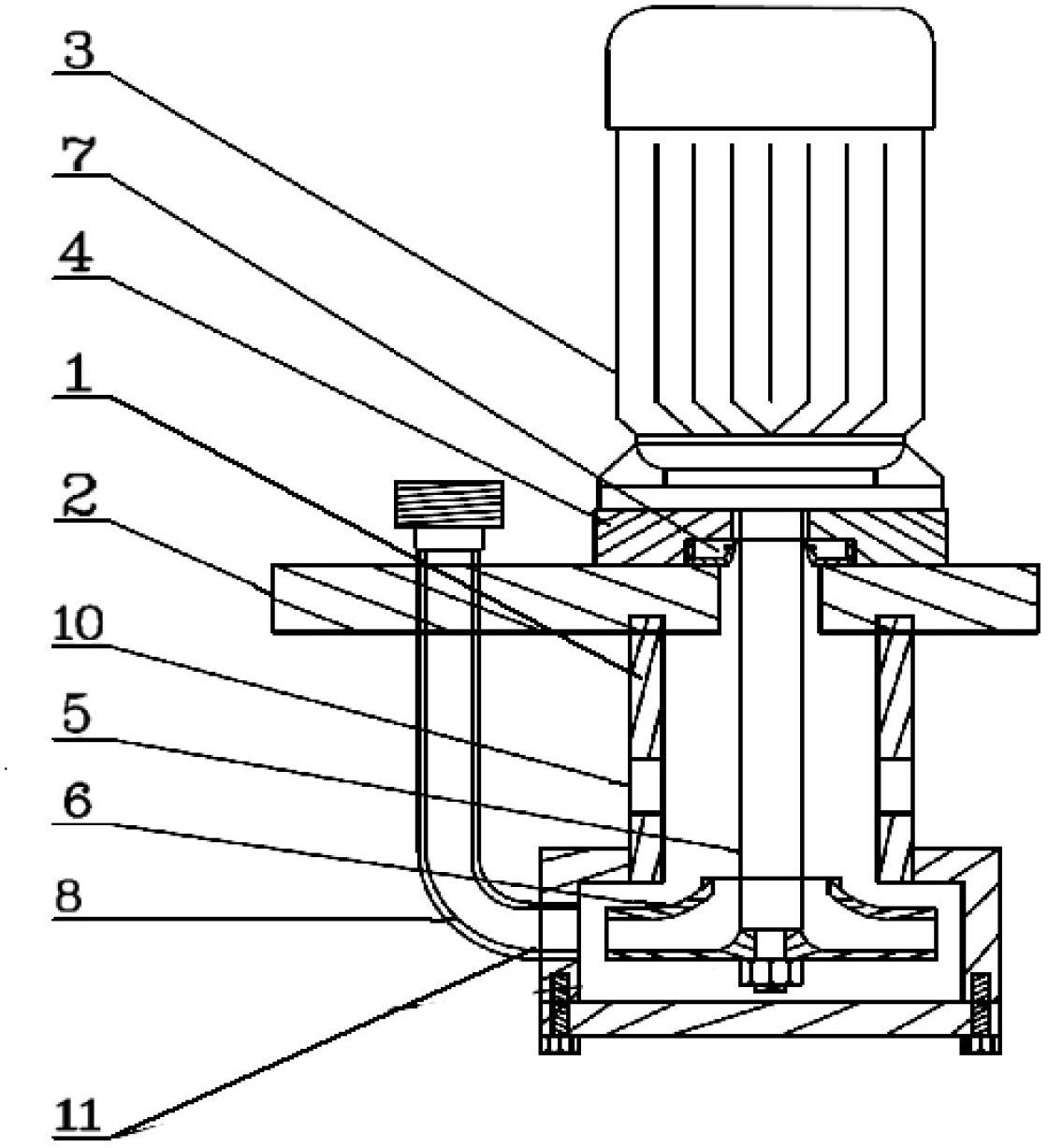

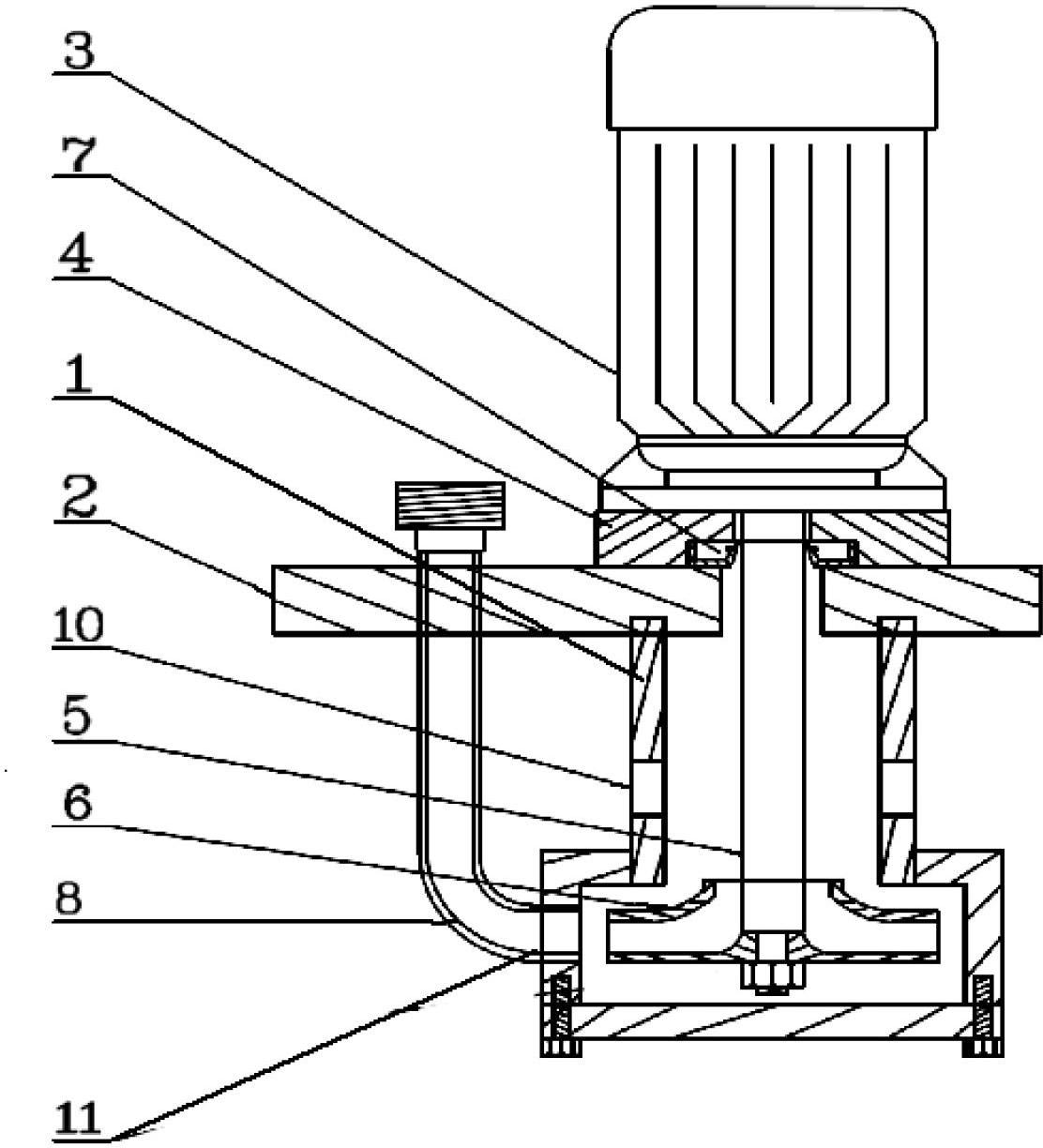

[0014] Such as figure 1 As shown, this embodiment provides a corrosion-resistant liquid pump for a circuit board etching machine, which includes a pump body with a liquid inlet 10 and a liquid discharge port 11, a fixing plate 2 for fixing the pump body 1, a motor 3, and a The motor bearing is connected to the motor 3, the motor support connecting plate 4, the rotating shaft 5 located in the pump body 1 and the upper end is connected to the shaft of the motor 3, and the impeller 6 fixedly arranged on the lower end of the rotating shaft 5, wherein: the impeller 6 sucks The mouth is upwardly installed on the lower end of the rotating shaft 5 , the liquid inlet 10 is located above the suction port of the impeller 6 , the liquid outlet 11 is substantially flat with the impeller 6 , and the liquid outlet 11 is connected with a liquid outlet pipe 8 . The outer diameter of the rotating shaft 5 is equal to the diameter of the shaft of the motor 3 . The rotating shaft 5 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com