Single-axis multi-directional cement mixing pile head and multi-axis multi-directional cement mixing pile head

A cement mixing pile and uniaxial technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of inability to mix cement and soil in multiple directions of the pile body, so as to ensure the quality of the pile body, high mixing efficiency, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

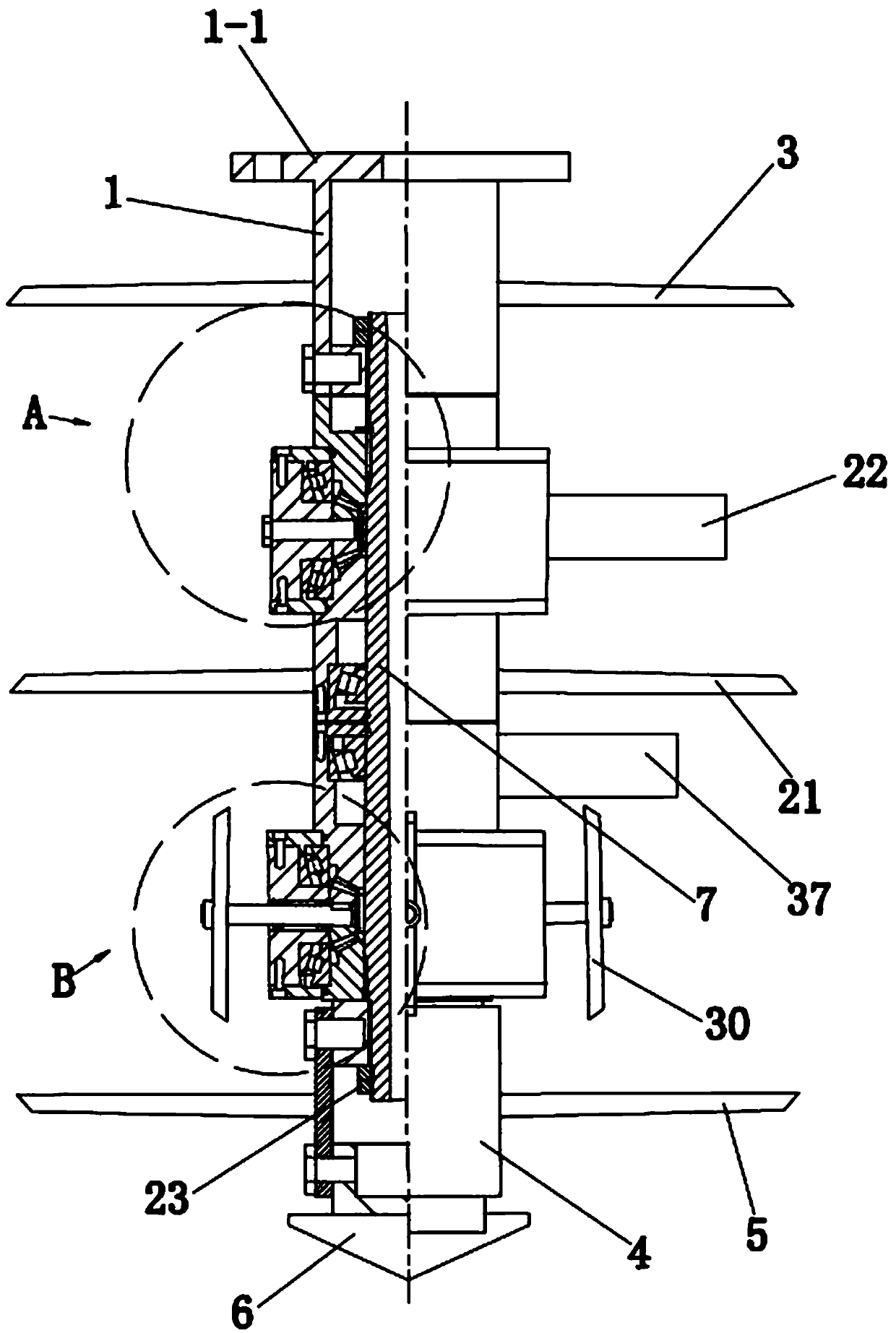

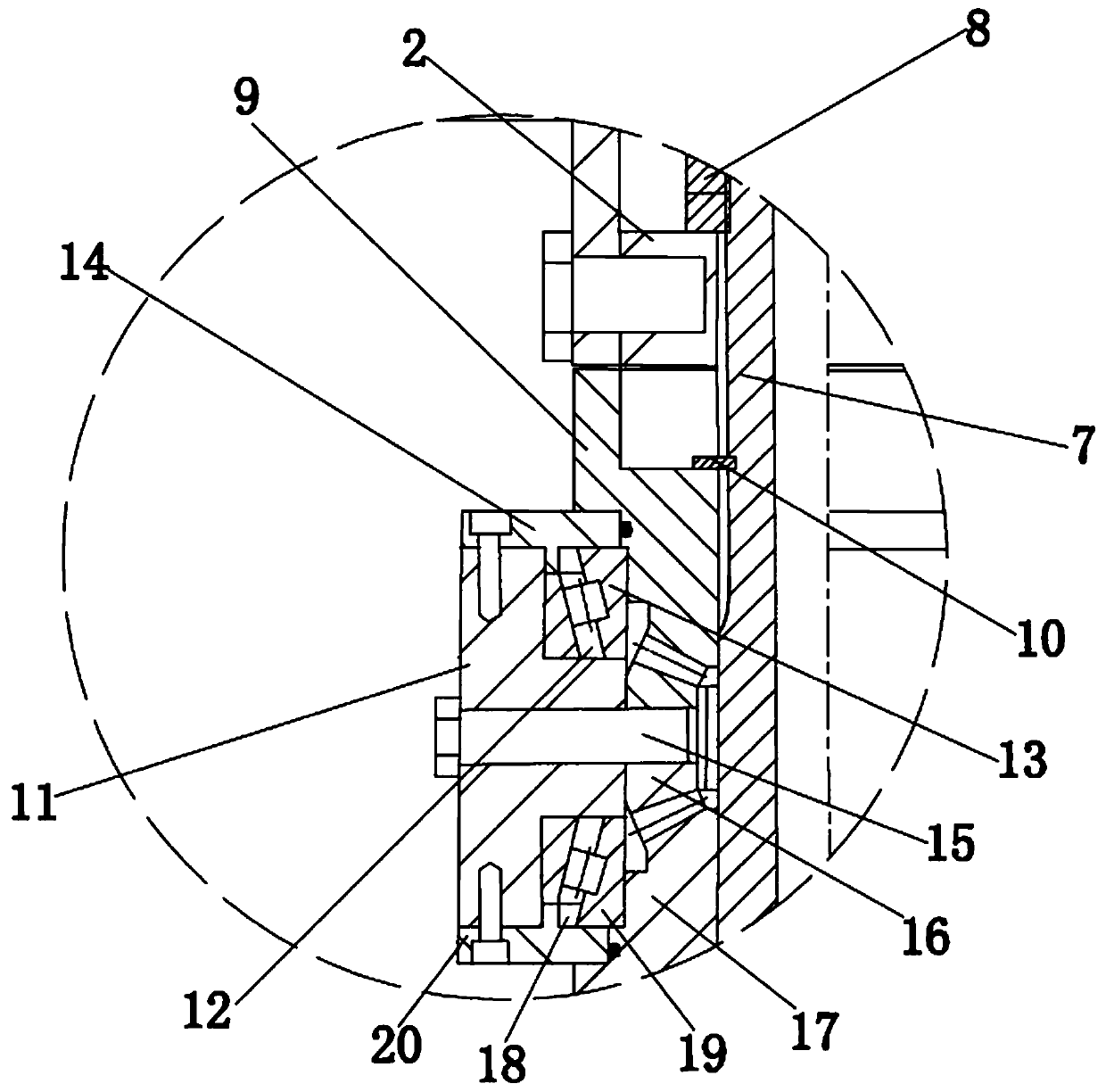

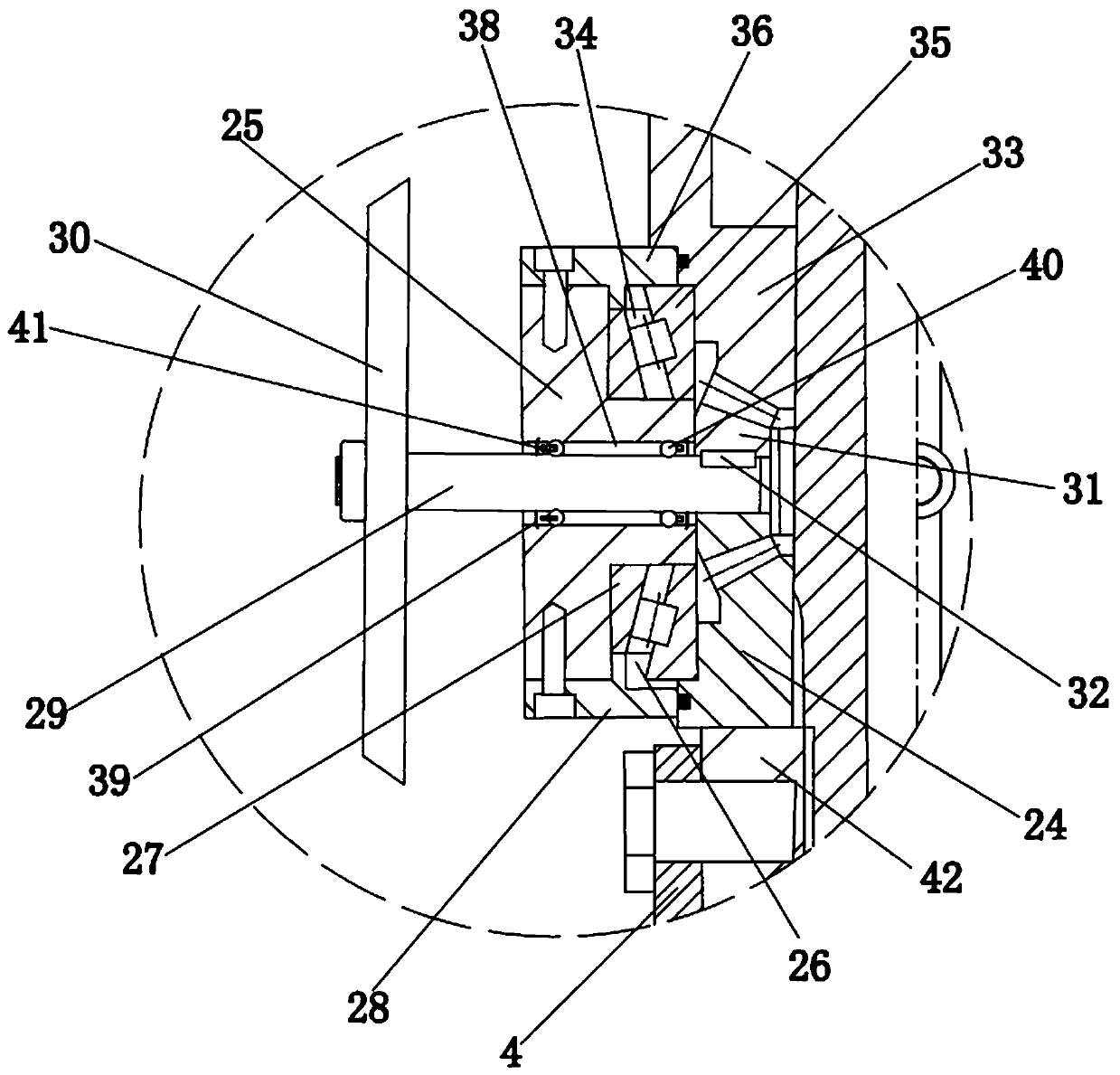

[0044] Such as Figure 1-3 As shown, as an embodiment, a uniaxial multidirectional cement mixing pile head provided in this embodiment includes:

[0045] A first rod assembly including:

[0046] A first set of rods 1, the first set of rods 1 is provided with a coupling disc 1-1, the coupling disc 1-1 is connected with the drill rod driven by the motor of the pile driver; a first spline sleeve 2, the first spline sleeve 2 The key sleeve 2 is fixed to the inside of the first set of rods 1 by bolt fasteners, and the two are in a coaxial structure; The ends of the first stirring blades 3 are all fixed to the first set of rods 1;

[0047] A second rod assembly, including:

[0048] A second set of rods 4; a second splined sleeve 42, the second splined sleeve 42 is fixed to the second set of rods 4 by bolt fasteners, and the two are coaxial structures; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com