LCD (liquid crystal display) panel and manufacturing method thereof

A technology for liquid crystal display panels and manufacturing methods, applied in lighting devices, optics, light sources, etc., capable of solving problems such as color shift and affecting the display effect of liquid crystal display panels, achieving good monochromaticity, improving display effects, and avoiding color shift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

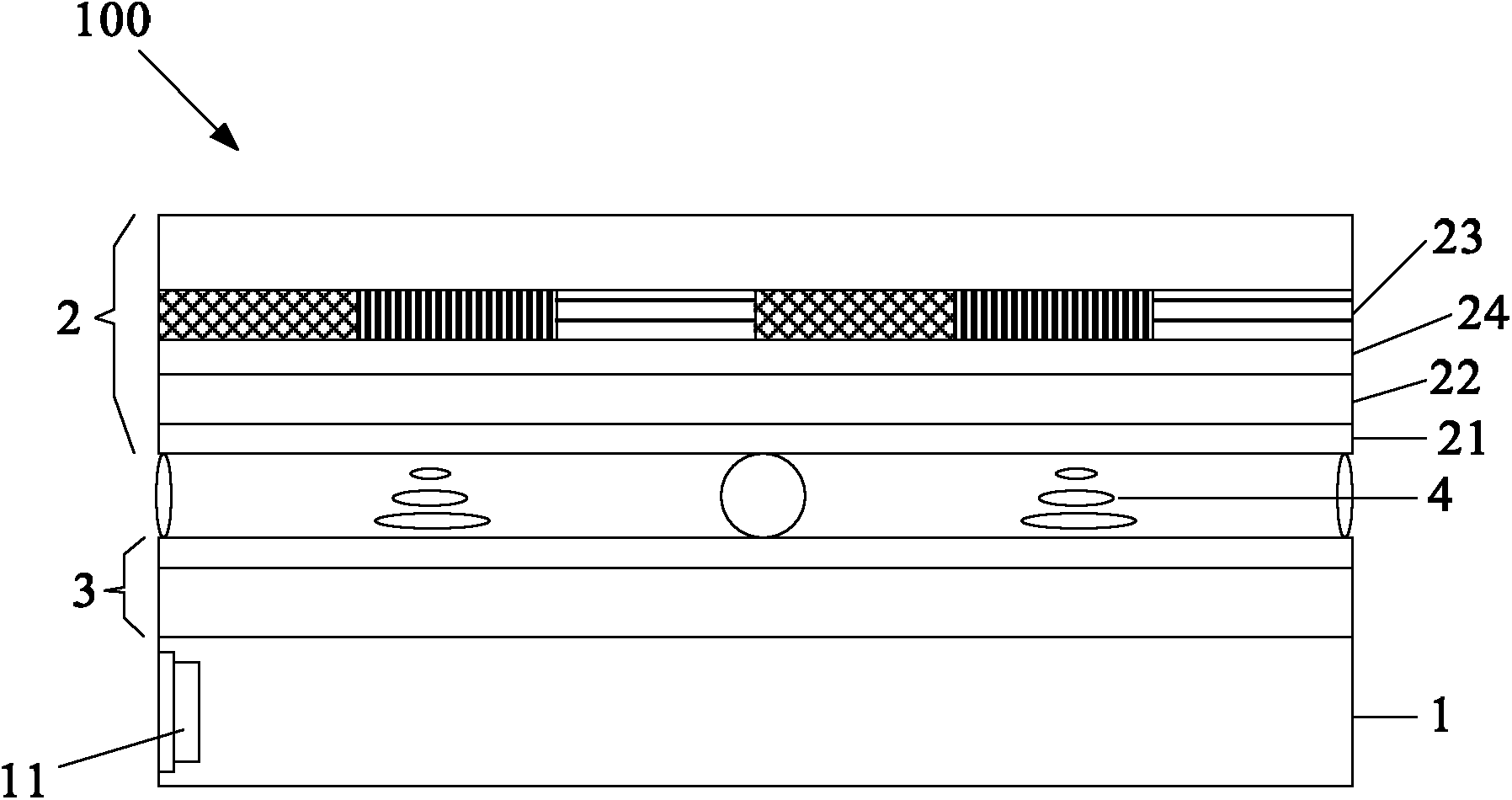

[0023] The liquid crystal display panel 100 provided by the embodiment of the present invention, such as figure 1 As shown, it includes: an LED backlight source 1, a color filter substrate 2 and a TFT array substrate 3 formed in a box, and a liquid crystal layer 4 located between the color filter substrate 2 and the TFT array substrate 3, wherein the color filter substrate 2 includes an orientation Film 21, common electrode layer 22 and color filter 23 (in figure 1 , the blue filter is represented by a vertical line filled area, the red filter is represented by a horizontal line filled area, and the green filter is represented by a grid line filled area). Further, the LED backlight 1 is a plurality of primary color LED chips 11; and on the color filter substrate 2, between the alignment film 21 and the color filter 23, a phosphor layer in which the primary color LED chips 11 form a complementary color is arranged. twenty four.

[0024] For example, if the primary color LED c...

Embodiment 2

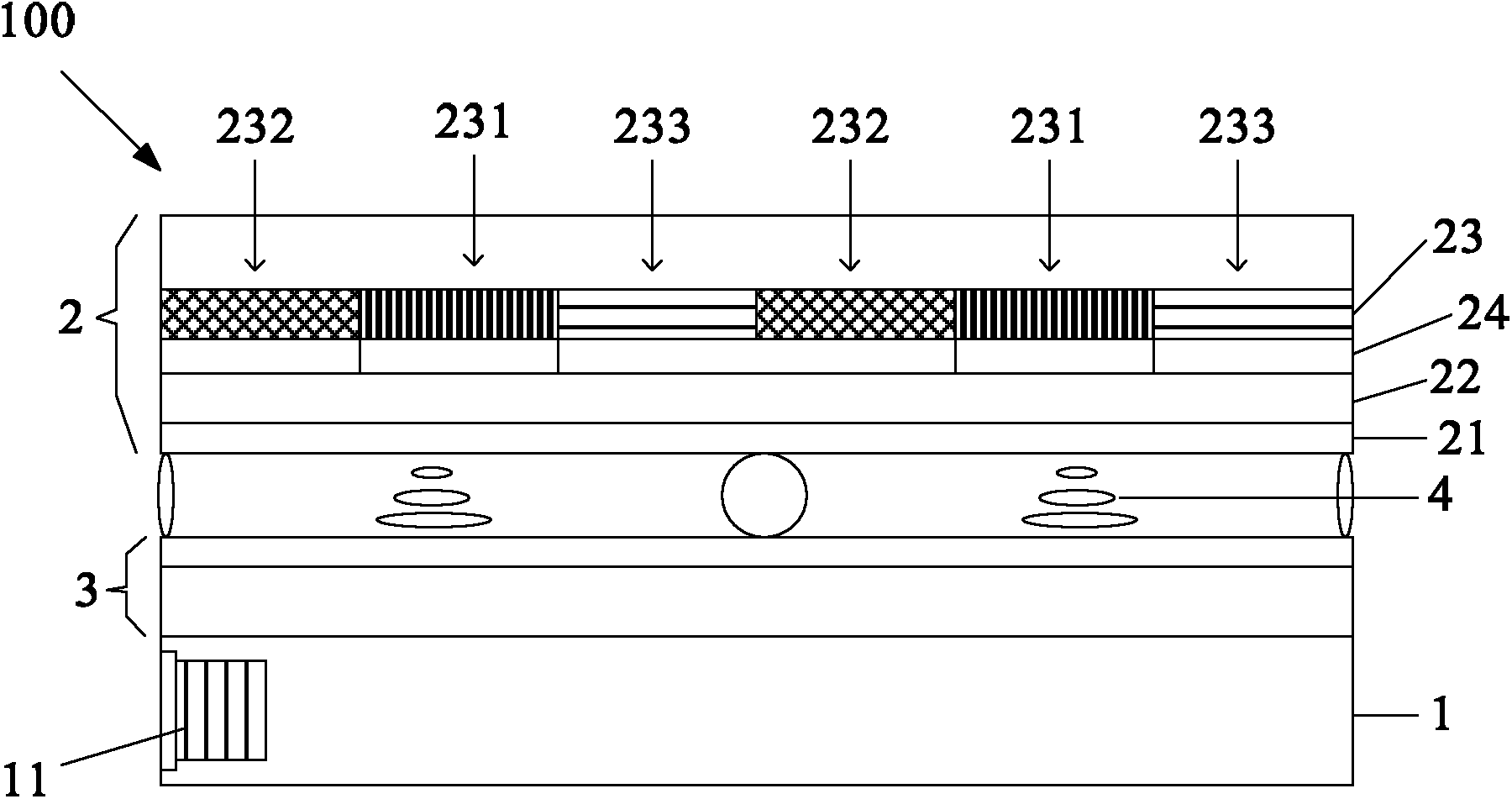

[0029] The liquid crystal display panel 100 provided by the embodiment of the present invention, such as figure 2 As shown, it includes: an LED backlight source 1, a color filter substrate 2 and a TFT array substrate 3 formed in a box, and a liquid crystal layer 4 located between the color filter substrate 2 and the TFT array substrate 3, wherein the color filter substrate 2 includes an orientation Film 21, common electrode layer 22 and color filter 23 (in figure 2 , the blue filter is represented by a vertical line filled area, the red filter is represented by a horizontal line filled area, and the green filter is represented by a grid line filled area). Further, the LED backlight 1 is a plurality of primary color LED chips 11; and on the color filter substrate 2, between the alignment film 21 and the color filter 23, a phosphor layer of the complementary color of the primary color LED chips 11 is arranged. twenty four.

[0030] In this embodiment, it is assumed that the ...

Embodiment 3

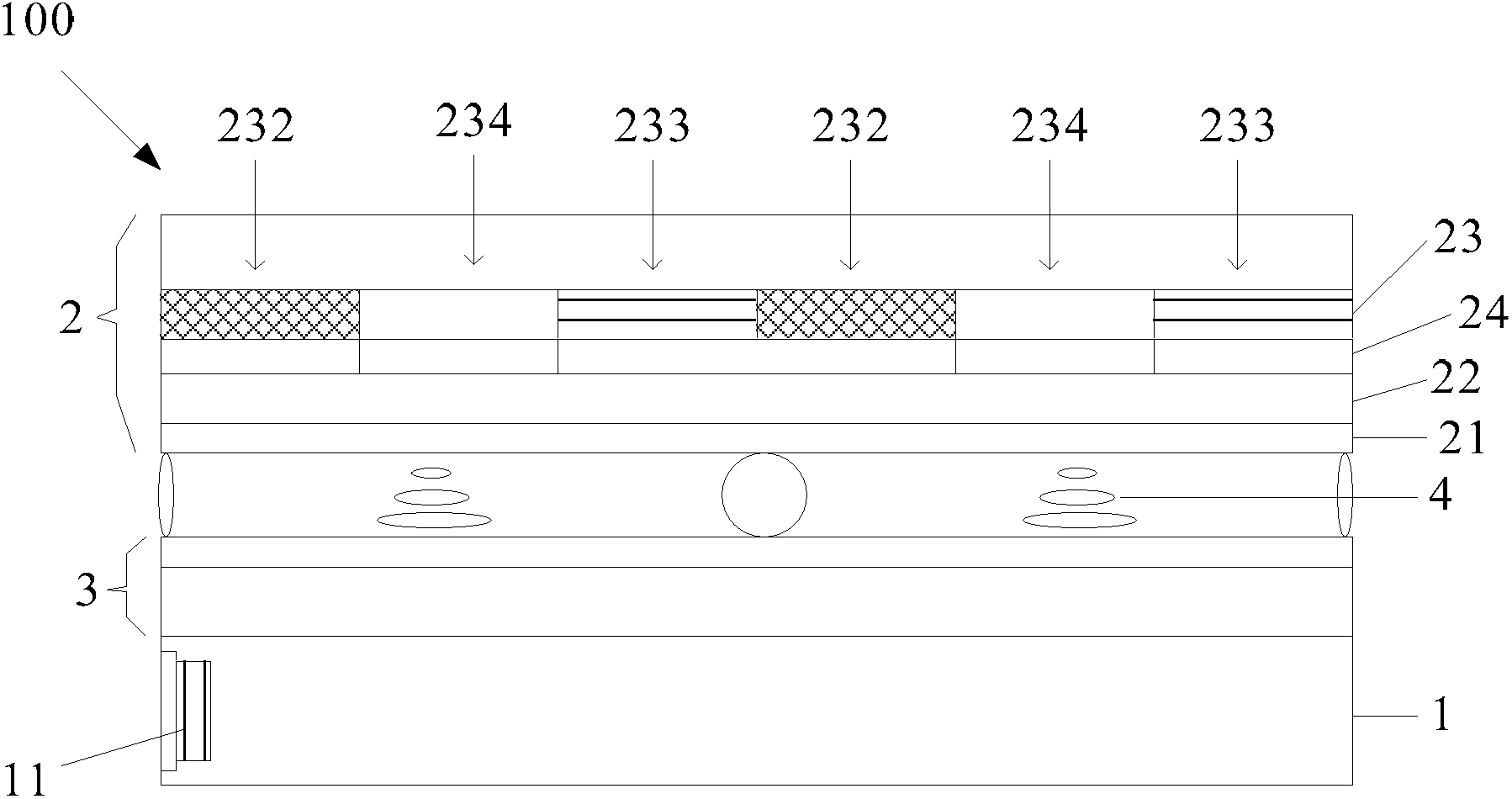

[0035] The liquid crystal display panel 100 provided by the embodiment of the present invention, such as image 3 As shown, it includes: an LED backlight source 1, a color filter substrate 2 and a TFT array substrate 3 formed in a box, and a liquid crystal layer 4 located between the color filter substrate 2 and the TFT array substrate 3, wherein the color filter substrate 2 includes an orientation Film 21, common electrode layer 22 and color filter 23 (in figure 2 , the blue filter is represented by a vertical line filled area, the red filter is represented by a horizontal line filled area, and the green filter is represented by a grid line filled area). Further, the LED backlight 1 is a plurality of primary color LED chips 11; and on the color filter substrate 2, between the alignment film 21 and the color filter 23, a phosphor layer of the complementary color of the primary color LED chips 11 is arranged. twenty four.

[0036] In this embodiment, it is assumed that the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com