An array substrate, a liquid crystal display panel and a liquid crystal display device

A technology for an array substrate and a color filter substrate, which is applied in the field of display devices, can solve the problems of poor quality of liquid crystal display panels, color shift of liquid crystal display panels, etc., and achieves the effect of avoiding color shift and improving display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

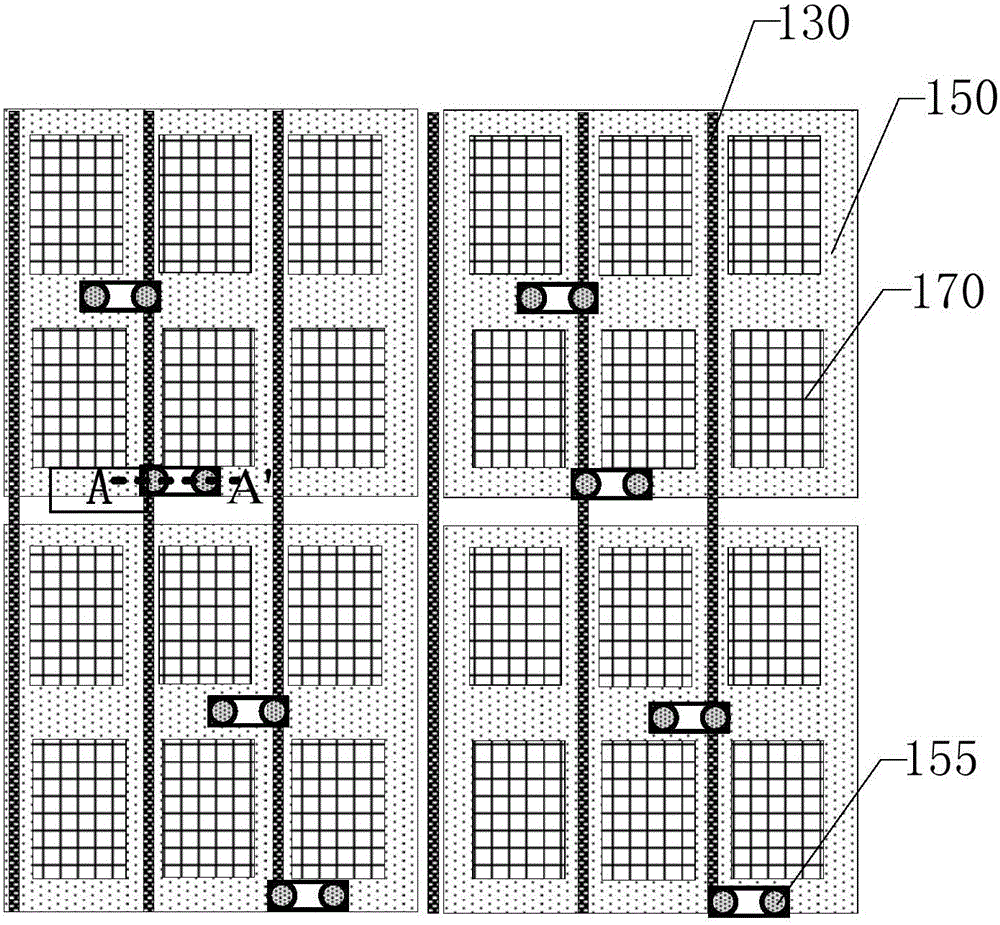

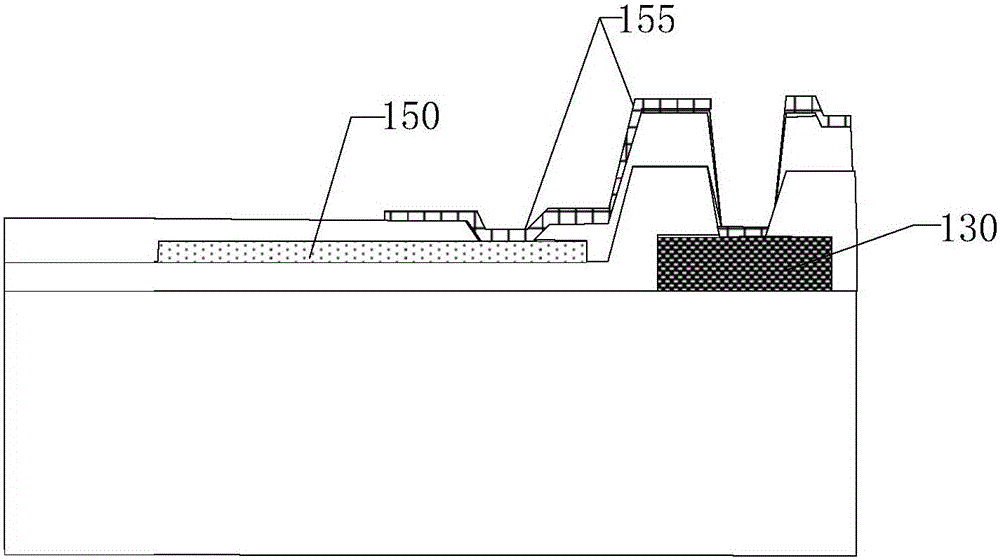

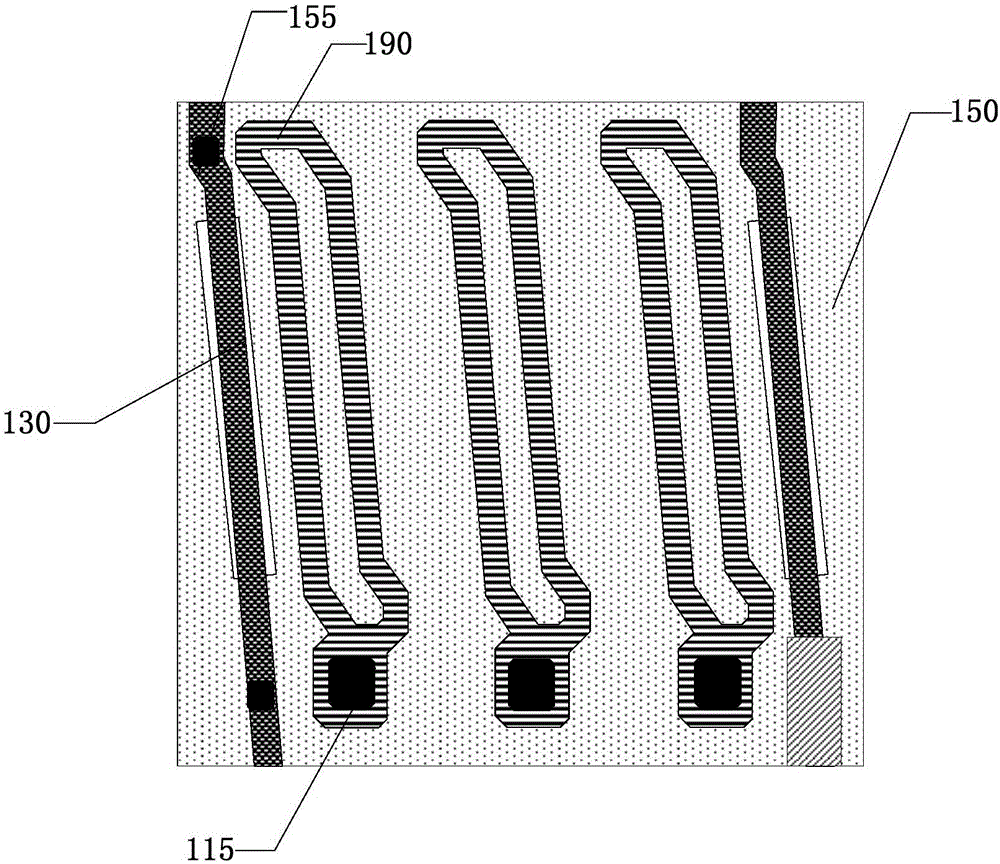

[0029] Figure 1a It is a partial top view diagram of the array substrate in the existing self-capacitance in-cell touch screen, Figure 1b for along Figure 1a Schematic cutaway of A-A'. combine Figure 1a and Figure 1b , the array substrate includes a plurality of common electrode blocks 150 and a plurality of sensing lines 130 , the common electrode blocks 150 are used for sensing user touch, and each sensing line 130 is electrically connected to a corresponding common electrode block 150 . Specifically, optionally, the sensing line 130 and the corresponding common electrode block 150 are electrically connected through the bridging structure 155, wherein the bridging structure 155 and the pixel electrode 170 are formed using the same metal layer, and the pixel electrode 170 is formed through the drain contact hole 115 is connected to the drain of the thin film transistor.

[0030] Wherein, the array substrate further includes a planarization layer 120 , a film layer wher...

no. 2 example

[0048] The second embodiment of the present invention also provides an array substrate. Figure 2a A schematic partial top view of an array substrate provided in the second embodiment of the present invention. see Figure 2a , the embodiment of the present invention and the first embodiment Figure 1e The arrangement of the auxiliary wires is the same, the difference is that each pixel electrode 170 is electrically connected to at least one auxiliary wire 180 .

[0049] The storage capacitor of the array substrate is mainly composed of the pixel electrode 170 and the common electrode block 150 . In a high-resolution touch screen, the smaller area of the pixel electrode 170 leads to a lower storage capacitance, which makes the existing high-resolution liquid crystal display panels prone to display defects such as flicker and crosstalk.

[0050] Figure 2b for along Figure 2a Schematic cutaway of BB'. combine Figure 2a and Figure 2b , in this embodiment, at least on...

no. 3 example

[0060] Based on the above embodiments, the third embodiment of the present invention provides an array substrate. The array substrate includes adjacent first pixel units, second pixel units, third pixel units and fourth pixel units, wherein there are two auxiliary wires between the adjacent first pixel units and the second pixel units, each At least one pixel electrode in each pixel unit is electrically connected to one of the auxiliary wires; there are two auxiliary wires between the adjacent third pixel unit and the fourth pixel unit, and at least one pixel electrode in each pixel unit is connected to one of the auxiliary wires. The auxiliary wires are electrically connected; there is no auxiliary wire between adjacent second pixel units and third pixel units.

[0061] image 3 It is a schematic partial top view of an array substrate provided by the third embodiment of the present invention. Such as image 3 As shown, there is a first auxiliary wire 181 and a second auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com