Non-circular stretching male die

A punch and non-circular technology, which is applied in the field of non-circular stretching punch molds, can solve the problems of inability to use materials with higher hardness for installation structures, complex manufacturing processes, and inability to improve precision, so as to save manufacturing costs and man-hours Less, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

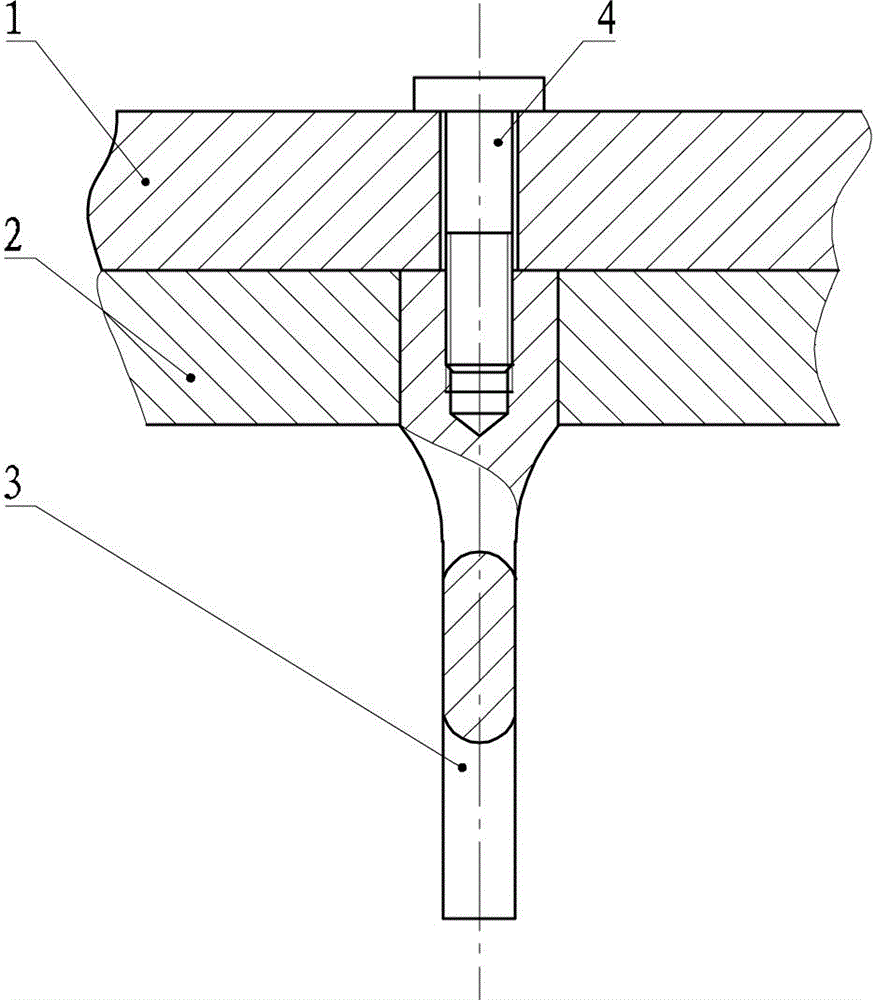

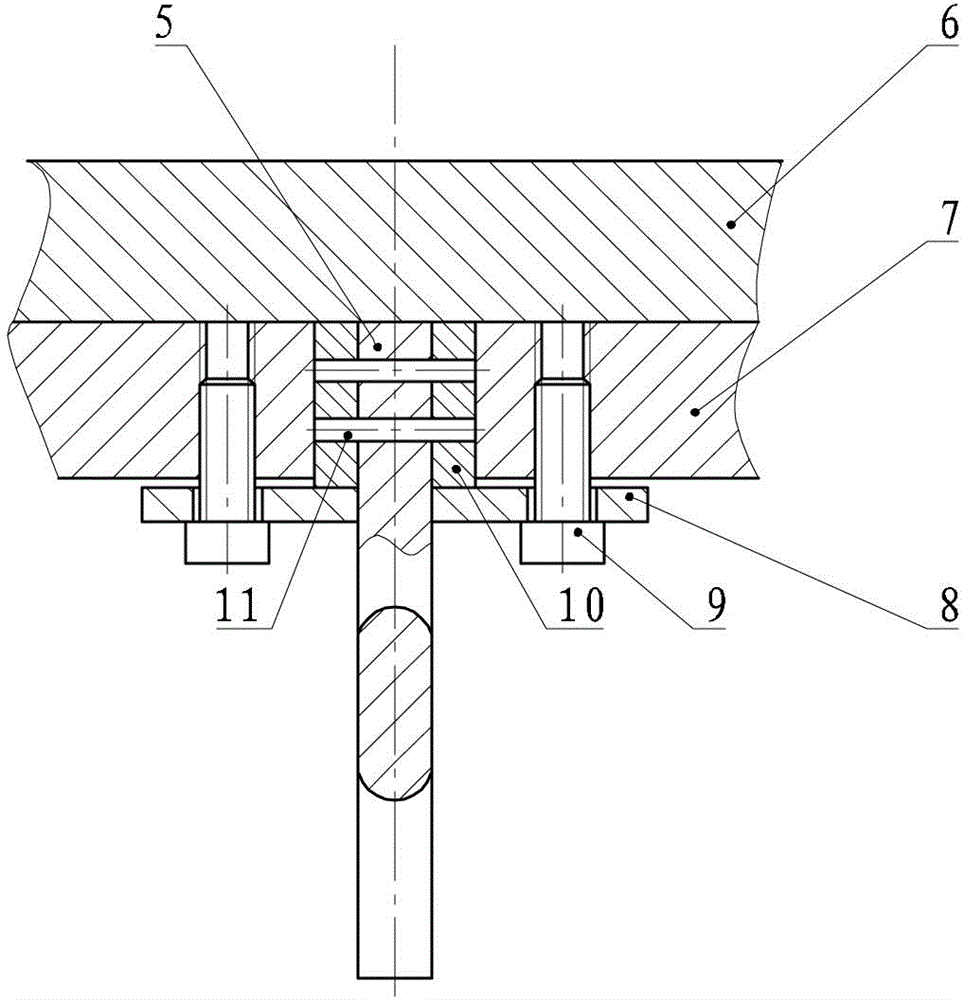

[0009] A non-circular drawing punch mold, with a non-circular cross-section bar of a qualified length cut out of a qualified length by a slow-moving wire cutting process made of hard alloy steel such as YG8, YG15, YG20, etc. , the cross-section of the phantom in this example is oblate, which is a composite shape of two ends of a rectangle and a semicircle. At its tail, there are two mounting holes vertical to the flat side and passing through the axis. There is a cuboid positioning sleeve, the axial position of which is provided with a cylindrical hole for transitional cooperation with the drawing punch, and the height of the positioning sleeve is greater than the thickness of the fixing plate installed on the stamping equipment. There are also two transverse holes on the positioning sleeve, which are coaxial and equal in diameter with the two mounting holes where the drawing punch is inserted into the positioning sleeve and put in place. After the drawing punch is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com