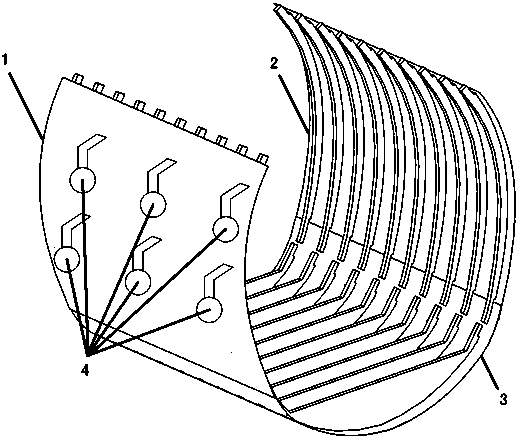

Wallboard insertion method based on polygonal approximation

A wallboard and mating technology, applied in the field of wallboard mating based on broken line approximation, can solve problems such as assembly interference, large curved wallboard size, complex shape, etc., to ensure accuracy, ensure coordinated movement, and suppress errors cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

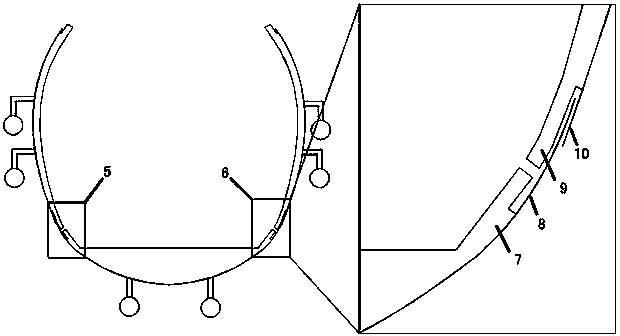

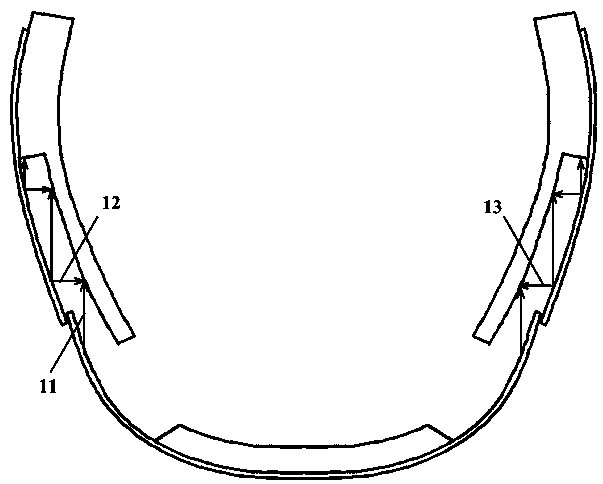

Method used

Image

Examples

Embodiment Construction

[0036] Such as Figure 4 As shown, the operation process of wall plate mating is as follows:

[0037] 1) Judging whether to perform wallboard mating for the first time, if so, go to step 2); otherwise, go to step 3);

[0038] 2) Calculate the initial pose of wall panel mating, design the polyline path, and enter the pose and path information into the database system 15, go to step 3);

[0039] 3) The process integration system 14 obtains the pose information and sends it to the lower attitude adjustment and positioning system 16, the left attitude adjustment and positioning system 17 and the right attitude adjustment and positioning system 18, and each attitude adjustment and positioning system drives the corresponding wallboard according to the pose information Translate to the starting pose, go to step 4);

[0040] 4) The process integration system 14 obtains the broken line path information and sends it to the lower attitude adjustment and positioning system 16, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com