External dredging machine for bin

A dredge machine and external technology, applied in the field of mining machinery, can solve the problems of difficult maintenance, repair or replacement, harsh working environment conditions, and shortened life of hydraulic cylinders, and achieve good working environment conditions, easy maintenance, and reduced resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

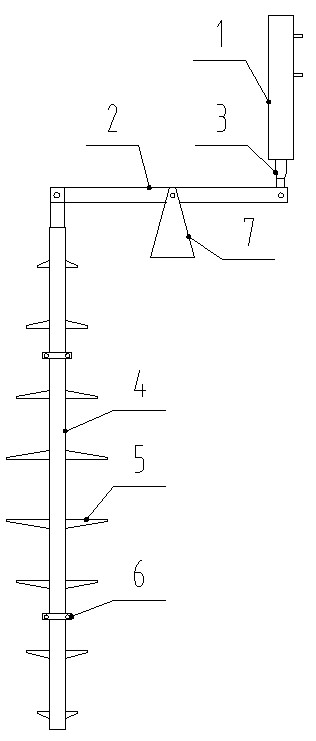

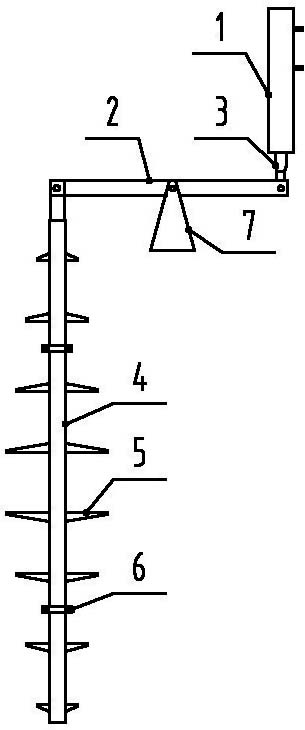

[0013] like figure 1 As shown, the external silo dredging machine of the present invention includes a hydraulic cylinder 1 and a dredging rake, the hydraulic cylinder 1 is vertically arranged outside the silo (not shown in the figure), the dredge rake is vertically arranged inside the silo, and the hydraulic cylinder The piston rod 3 of 1 is connected with the dredging rake through a driver.

[0014] The dredging rake includes a vertically arranged push-pull rod 4, and the push-pull rod 4 is axially and horizontally provided with several scrapers 5. The limit device 6 (the limit device is an existing mature technology, and the specific structure will not be described in detail), the limit device 6 plays a role in limiting the left and right swing of the push-pull rod 4, and provides a slideway for the push-pull rod 4 to move up and down; The fixed bracket 7 on the feed bin and the lever 2 hinged on the fixed bracket 7, one end of the lever 2 is hinged with the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com