Preparation method of polarization modified iron-carbon micro-electrolysis material

An iron-carbon micro-electrolysis and modification technology, which is applied in the field of water treatment, can solve problems such as scrapping of reaction tanks, uneven mixing of iron and carbon, and collapse of iron filings or steel filings, so as to save equipment investment and operating costs, and improve reaction speed, effects that improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of a polarized modified iron-carbon micro-electrolytic material:

[0024] A, choosing iron content is 300 parts by weight of low-carbon steel material of 60%;

[0025] B, above-mentioned material is pulverized into 100 order fine powders with pulverizer;

[0026] C, above-mentioned fine powder is processed through magnetic separation, makes the iron content in the iron material after processing reach 90%;

[0027] D. Add 8 parts by weight of isocyanate to the above material at a temperature of 1500 ° C, and incorporate 8 parts by weight of nano-attapulgite when it enters the foaming stage, and polarize the material to make the material have good hydrophilicity. And enhance the anode and cathode performance of its redox reaction;

[0028] E. After the above polarization reaction for 15 minutes, add 1.5 parts by weight of dimethyl silicone oil, stir for 15 minutes, and cool to room temperature;

[0029] F, pulverize the polarized material to 20 mesh particl...

Embodiment 2

[0032] Preparation of a polarized modified iron-carbon micro-electrolytic material:

[0033] A, choosing iron content is 200 parts by weight of low-carbon steel material of 70%;

[0034] B, above-mentioned material is pulverized into 300 mesh fine powders with pulverizer;

[0035] C, above-mentioned fine powder is processed through magnetic separation, makes the iron content in the iron material after processing reach 90%;

[0036] D. Add 3 parts by weight of isocyanate to the above material at a temperature of 1500°C, and incorporate 5 parts by weight of nano-attapulgite when it enters the foaming stage, and perform polarization modification on the material to make the material have good hydrophilicity and enhance the anode and cathode performance of its redox reaction.

[0037] E. After the above polarization reaction for 15 minutes, add 1 part by weight of dimethyl silicone oil, stir for 15 minutes, and cool to room temperature;

[0038] F, pulverize the material after p...

Embodiment 3

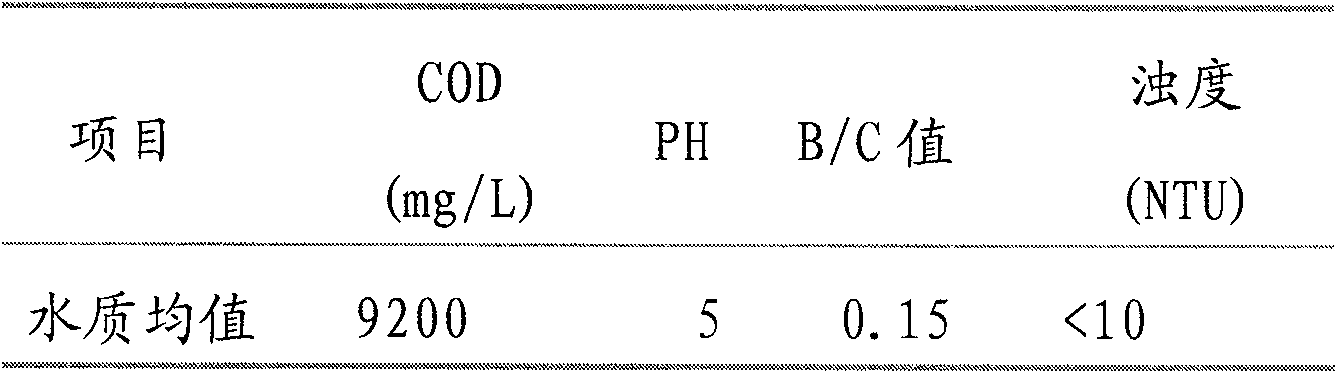

[0042] An application example of a company using the material of the present invention to treat high-concentration organic chemical wastewater

[0043] 1, the preparation of the iron-carbon micro-electrolytic material of polarization modification of the present invention:

[0044] A, choosing iron content is 100 parts by weight of low-carbon steel material of 65%;

[0045] B, above-mentioned material is pulverized into 200 order fine powders with pulverizer;

[0046] C, above-mentioned fine powder is processed through magnetic separation, makes the iron content in the iron material after processing reach 90%;

[0047] D. Add 5 parts by weight of isocyanate to the above material at a temperature of 1500 °C, and incorporate 10 parts by weight of nano-attapulgite when it enters the foaming stage, and polarize the material to make the material have good hydrophilicity. And enhance the anode and cathode performance of its redox reaction;

[0048] E. After the above polarization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com